Abstract

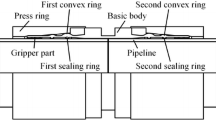

For better film characteristics of the main pump seal (MPS), a theoretical calculation model was proposed based on the Reynolds equation. A case study with defined MPS was carried out, film stiffness was taken as the basic constraint condition, and the cone angle and clearance are two optimization targets. When the film stiffness reaches a maximum, the corresponding cone angle and clearance is the optimal value. The results show that: (1) film stiffness increased and decreased with clearance and cone angle, respectively; (2) the optional clearance was determined to be within a range of 2~8 µm at a cone angle of between 0.1~1.2′; (3) the maximum of film stiffness is inversely proportional to the cone angle (Clearance) approximately under the clearance (Cone angle) is fixed; (4) leakage is directly proportional to the clearance to power three, and the clearance has greater influence on the amount of leakage than the cone angle. These results provide a reliable theoretical justification for MPS-based designs including optimization method. It therefore forms a fundamental base for research and practical application.

Similar content being viewed by others

References

R. P. Gabriel, Fundamentals of spiral groove noncontacting face seals, Lubrication Engineering, 50 3 1994 215–224.

W. B. Zhu, H. S. Wang and L. Dong, Design and performance analysis of dual vibrating motors self synchronous shaker with balanced elliptical motion, Applied Mechanics and Materials, 284 2013 677–680.

H. K. Müller and G. W. Ott, Dynamic sealing mechanism of rubber rotary shaft seals, 10th International Conference on Fluid Sealing, NS Nau (Ed.), USA (1984) 451–466.

A. Djamai, N. Brunetiere and B. Tournerie, Numerical modeling of thermohydrodynamic mechanical face seals, Tribology Transactions, 53 3 2010 414–425.

T. Koga and T. Fujita, The hydrostatic noncontact seal including fluid inertia effect, ASLE Transactions, 29 1 1986 35–42.

N. Brunetiere, A modified turbulence model for low Reynolds numbers: Application to hydrostatic seals, J. of Tribology, 127 1 2005 130–140.

N. Brunetière, E. Galenne, B. Tournerie and I. Pierre-Danos, Modelling of non-laminar phenomena in high reliability hydrostatic seals operating in extreme conditions, Tribology International, 41 4 2008 211–220.

E. Galenne and I. Pierre-Danos, Thermo-elasto-hydro-dynamic modeling of hydrostatic seals in reactor coolant pumps, Tribology Transactions, 50 4 2007 466–476.

N. Brunetière, B. Tournerie and J. Fre, Influence of fluid flow regime on performances of non-contacting liquid face seals, J. of Tribology, 124 3 2002 515–523.

X. Hao, Seal, Metallurgical Industry Press, Beijing, China (1999).

R. F. Salant and B. Cao, Unsteady analysis of a mechanical seal using Duhamel’s method, J. of Tribology, 127 3 2005 623–631.

J. K. Lee, M. Naganuma, J. Park and A. Kohyama, Investigation on fabrication of SiC/SiC composite as a candidate material of fuel sub-assembly, Proceedings of Global (2005).

W. Kim, H. S. Hwang, J. Y. Park and W. R. Seog, Corrosion behaviors of sintered and chemically vapor deposited silicon carbide ceramics in water at 360 C, Journal of Materials Science Letters, 22 8 2003 581–584.

Z. Xinmin, X. Yanqiu, Z. Qing and F. Xin, Analysis for rotordynamic coefficients of partially tapered short annular seals, Lubrication Engineering, 163 3 2004 71–75.

H. Zhenmin, W. Qinhu, C. Zhipeng and H. Ye, Theory research and application of using temperature control method to avoid the nuclear main pump high stops due on the 1st shaft seal high leakage, Pump Technology, 2008 6 2008 7–13.

Z. Luan and M. Khonsari, Numerical simulations of the flow field around the rings of mechanical seals, J. of Tribology, 128 3 2006 559–565.

D. Weiqi, C. Jining, Z. Qiuxiang and L. Shuangxi, Numerical simulation of flow in convergent wedgelike gap hydrostatic mechanical seal, Lubrication Engineering, 33 6 2008 31–34.

M. Dongbo, C. Jining, Z. Qiuxiang and L. Shuangxi, Study on the seal property of the second seals of reactor coolant pump in nuclear station from contacting to non-contacting mechanical seal, Lubrication Engineering, 34 7 2009 33–37.

A. O. Lebeck, M. E. Nygren, S. A. Shirazi and R. Soulisa, Fluid Temperature and Film Coefficient Prediction and Measurement in Mechanical Face Seals—Experimental Results, Tribology Transactions, 41 4 1998 411–422.

J. D. Summers-Smith, Mechanical seal practice for improved performance, Mechanical Engineering for the Institution of Mechanical Engineers, London, UK (1988).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jun Sang Park

Wang Heshun is a professor at Xihua University, Chengdu, China. He received his Ph.D. in Mechanical Design&Theory from Southwest Jiaotong University, Chengdu, China. He is a director of the institute of engineering graphics organization. His main research interests include mechanical seals design, seal flow numerical simulations and engineering drawing.

Zhu Weibing is a professor at Xihua University, Chengdu, China. He received his Ph.D. in Mechanical Design&Theory from Southwest Petroleum University, Chengdu, China. He is the director of the institute of mechanical transmission. His main research interests include oil well vibrating screen, transmission seals design, and numerical simulations.

Huang Zepei is a professor senior engineer at Sichuan Nikki Seal Co. Ltd., Chengdu, China. He is a visiting scholar in metallurgy material school of Birmingham University, Birmingham, United Kingdom. His main research interests include mechanical seals design and process, materials of seal and pump technology.

Zhang Chening is a professor senior engineer at Sichuan Nikki Seal Co. Ltd., Chengdu, China. He is the director of technical department. He received his B.S. in Chemical Mechanicals from Sichuan University, Chengdu, China. His main research interests include dry gas seals design, control system of seal and materials of seals.

Zhang Junkai is a professor senior engineer at Sichuan Nikki Seal Co. Ltd., Chengdu, China. He is the director of unclear power seal department. He received his B.S. in Agricultural Mechanical from Southwest University, Chongqing, China. His main research interests include nuclear power seals design, oil seals and floating ring seals.

Rights and permissions

About this article

Cite this article

Wang, H., Zhu, W., Huang, Z. et al. Research on the cone angle and clearance of main pump seal. J Mech Sci Technol 29, 2939–2947 (2015). https://doi.org/10.1007/s12206-015-0239-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-0239-2