Abstract

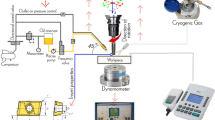

This work investigated the influence of cutting speed and feed rate on cutting forces, surface roughness, and slot width circular sawing of AISI 1045 steel. The effects of tool material (cermet and tungsten carbide) and geometry (chip breaker flute and pre-cutting/post-cutting teeth) were also investigated. Thrust and radial forces generally tended to decrease as the cutting speed increased and tended to increase with the feed rate. The lowest values of thrust and radial forces were obtained using a tungsten carbide saw ground with precutting and post-cutting teeth. With regard to the quality of the machined wall, the lowest surface roughness was obtained by applying the highest cutting speed and lowest feed rate and employing a cermet brazed saw. Under this condition, roughness values comparable to face turning and parting off operations were obtained. The cermet brazed saw was responsible for producing the narrowest slot widths.

Similar content being viewed by others

References

C. S. Kim, K. S. Hong and M. K. Kim, Nonlinear robust control of a hydraulic elevator, Control Engineering Practice, 13(6) (2005) 789–803.

F. Klocke, Manufacturing Process 1: Cutting, vol 1, Springer-Verlag, Berlin-Heidelberg, Germany (2011).

G. Schneider, Principles of tungsten carbide engineering: Expanded and up-dated to include ceramics, 2nd ed., ASM International, Materials Park, USA (1989).

Y. K. Hwang and C. M. Lee, Surface roughness and cutting force prediction in MQL and wet turning process of AISI 1045 using design of experiments, J. Mech. Sci. Technol., 24(8) (2010) 1669–1677.

M. Tillmann, Schlussbericht: Schnellsttrennen von stahl mit hochharten schneidstoffen, 15958 N: Industriellen Gemeinschaftsforschung (IGF), Remscheid, Germany (2011).

M. Sawar, J. Haider, M. Persson and H. Hellberg, Forces, wear modes, and mechanisms in bandsawing steel work-pieces, Proc. Inst. Mech. Eng. Part B: J.Eng. Manuf., 224 (2009) 1655–1662.

S. R. Bradbury and D. B. Lewis, A comparison of the performance and wear characteristics of high-speed steel circular saw blades machining Nimonic PK31, AISI O1 tool steel, Inconel 600L and AISI 1018 carbon steel, J. Mater. Sci., 35 (2000) 1511–1524.

H. W. Lee and W. T. Kwon, Determination of the minute range for RSM to select the optimum cutting conditions during turning on CNC lathe, J. Mech. Sci. Technol., 24(8) (2010) 1637–1645.

H. Tschätsch and J. Dietrich, Praxis der Zerpantechnik: Verfahren, Werzeuge, Berechnung, 9 Aufl, Vieweg + Teubner, Wiesbaden, Germany (2008).

Kistler Instrumente AG Winterthur, 3-Component Dynamometer Fx, Fy, Fz, Technical Brochure Nr. 6.9257BA, Ed. 11.95, Winterthur, Switzerland (1995).

T. Childs, K. Maekawa, T. Obikawa and Y. Yamane, Metal machining — Theory and applications, arnold, London, UK (2000).

M. Sawar, M. Persson, H. Hellberg and J. Haider, Measurement of specific cutting energy for evaluating the efficiency of bandsawing different workpiece materials, Int. J. Mach. Tools Manuf., 49 (2009b) 958–965.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jihong Hwang

A. M. Abrão received his Ph.D. from the School of Manufacturing and Mechanical Engineering of the University of Birmingham, UK, in 1995. Currently, he is an associate professor at the Department of Mechanical Engineering of the University of Minas Gerais, Brazil. His main fields of interest are cutting by shearing, nonconventional machining and abrasive processes.

Rights and permissions

About this article

Cite this article

Abrão, A.M., Moreira, M.C., Faria, P.E. et al. High-performance circular sawing of AISI 1045 steel with cermet and tungsten carbide inserts. J MECH SCI TECHNOL 28, 4275–4282 (2014). https://doi.org/10.1007/s12206-014-0941-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0941-5