Abstract

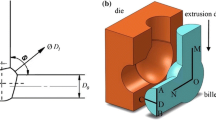

A new severe plastic deformation (SPD) method based on equal channel angular pressing (ECAP) is introduced for producing ultrafine grains in bulk alloys, entitled as “Planar twist channel angular extrusion (PTCAE)”. In PTCAE method, there is additional angle, α, (plus φ and ψ angles in ECAP method) which represents angle associated with the lateral reversal arc of curvature in deformation zone. Three dimensional finite element method (FEM) simulations of both ECAP and PTCAE processes were performed in order to investigate the plastic deformation state of processed samples and, moreover, the effect of different die geometry (in terms of variation of planar twist angle) on plastic strain distribution and magnitude. Results revealed that PTCAE process related with ECAP process can impose higher strain values in different shear planes simultaneously in one deformation zone. Therefore, PTCAE can produce UFG or nanostructured materials better than ECAP method which has simpler design and significantly higher efficiency compared with other new SPD processes.

Similar content being viewed by others

References

R. Z. Valiev, R. K. Islamgaliev and I. V. Alexandrov, Bulk nanostructured materials from severe plastic deformation, Progress in Materials Science, 45 (2000) 103–189.

R. Kocich, M. Greger, M. Kursa, I. Szurman and A. Machackova, Twist channel angular pressing (TCAP) as a method for increasing the efficiency of SPD, Materials Science and Engineering: A, 527 (2010) 6386–6392.

R. Z. Valiev and T. G. Langdon, Principles of equal-channel angular pressing as a processing tool for grain refinement, Progress in Materials Science, 51 (2006) 881–981.

K. Nakashima, Z. Horita, M. Nemoto and T. G. Langdon, Influence of channel angle on the development of ultrafine grains in equal channel angular pressing, Acta materiala, 46(5) (1998) 1589–1599.

E. Cerri, P. P. De Marco and P. Leo, FEM and metallurgical analysis of modified 6082 aluminium alloys processed by multipass ECAP: Influence of material properties and different process settings on induced plastic strain, Materials Processing Technology, 209 (2009) 1550–1564.

B. Talebanpour, R. Ebrahimi and K. Janghorban, Microstructural and mechanical properties of commercially pure aluminum subjected to dual equal channel lateral extrusion, Materials Science and Engineering: A. b527 (2009) 141–145.

B. Talebanpour and R. Ebrahimi, Upper-bound analysis of dual equal channel lateral extrusion, Materials and Design, 30 (2009) 1484–1489.

B. Mani, M. Jahedi and M. H. Paydar, Consolidation of commercial pure aluminum powder by torsional-equal channel angular pressing (T-ECAP) at room temperature, Powder Technology, 219 (2012) 1–8.

A. Rosochowski and L. Olejnik, Finite element analysis of two-turn Incremental ECAP, International Journal of Materials Forum, 1 (2008) 483–486.

O. Bouaziz, Y. Estrin and H. S. Kim, A new technique for severe plastic deformation: The cone-cone method, Advanced Engineering Materials, 12 (2009) 982–985.

Y. Beygelzimer, V. Varyukhin, S. Synkov and D. Orlov, Useful properties of twist extrusion, Materials Science and Engineering: A, 503 (2009) 14–17.

Y. Beygelzimer, V. Varyukhin and S. Synkov, Shears, vortices, and mixing during twist extrusion, International Journal Materials Forum, 1 (2008) 443–446.

Y. Beygelzimer, D. Prilepo, R. Kulagin, V. Grishaev, O. Abramova, V. Varyukhin and M. Kulakov, Planar twist extrusion versus twist extrusion, Materials Processing Technology, 211 (2011) 522–529.

N. Pardis and R. Ebrahimi, Deformation behavior in simple shear extrusion (SSE) as a new severe plastic deformation technique, Materials Science and Engineering: A, 527 (2009) 355–360.

N. Pardis and R. Ebrahimi, Different processing routes for deformation via simple shear extrusion (SSE), Materials Science and Engineering: A, 527 (2010) 6153–6156.

A. Zangiabadi and M. Kazeminezhad, Development of a novel severe plastic deformation method for tubular materials: Tube channel pressing (TCP), Materials Science and Engineering: A, 528 (2011) 5066–5072.

N. Pardis, B. Talebanpour, R. Ebrahimi and S. Zomorodian, Cyclic expansion-extrusion (CEE): A modified counterpart of cyclic extrusion-compression (CEC), Materials Science and Engineering: A, 528 (2011) 7537–7540.

M. Shamsborhan and A. Shokuhfar, A planar twist channel angular extrusion (PTCAE) as a novel severe plastic deformation method based on equal channel angular extrusion (ECAE) method, Proc. IMechE. Part C: Journal of Mechanical Engineering Science, doi:10.1177/0954406213515645.

N. Q. Chinh, G. Horvath, Z. Horita and T. G. Langdon, A new constitutive relationship for the homogeneous deformation of metals over a wide range of strain, Acta Materialia, 52 (2004) 3555–3563.

F. Djavanroodi and M. Ebrahimi, Effect of die channel angle, friction and back pressure in the equal channel angular pressing using 3D finite element simulation, Materials Science and Engineering: A, 527 (2010) 1230–1235.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Seong Beom Lee

Mahmoud Shamsborhan is presently a Ph.D. Candidate in the department of mechanical engineering at K. N. Toosi University of Technology (KNTU), Tehran, Iran. He is the member of the Advanced Materials and Nanotechnology Research Laboratory at K. N. Toosi University of Technology since under the supervision of Professor Ali Shokuhfar. His scientific interests include Severe Plastic Deformation (SPD), FEM Simulation, Biomechanics and Full Anatomical Modeling of Biological Tissues. He has published more than 15 papers in national and international journals and conferences. Also, he has one Iranian patent.

Rights and permissions

About this article

Cite this article

Shokuhfar, A., Shamsborhan, M. Finite element analysis of planar twist channel angular extrusion (PTCAE) as a novel severe plastic deformation method. J Mech Sci Technol 28, 1753–1757 (2014). https://doi.org/10.1007/s12206-014-0321-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0321-1