Abstract

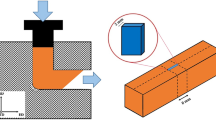

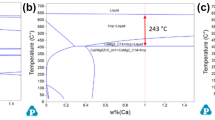

The workability of ZK60A billets fabricated by semi-continuous casting, subsequent extrusion, and die casting were evaluated. To determine the deformation capability of the three different billets, upsetting tests were conducted at elevated temperatures and two different strain rates. The differences in critical height reduction depending on the casting methods were investigated based on inherent defects inside the billets, and variation in the mechanical property with the location within the semi-continuously casted billet was investigated by X-ray tomography and electron backscatter diffraction. Uniformity of density substantially affected the mechanical properties of the billet. The drastic decrease in the workability of the die-casted billet at temperatures higher than 320°C was also discussed.

Similar content being viewed by others

References

H. E. Friedrich and B. L. Mordike, Magnesium technology, Springer, Berlin Heidelberg (2010).

F. Czerwinski, Magnesium injection molding, Springer, NY (2008).

M. M. Avedesian, N. Magnesium Inc. And H. Baker, ASM specialty handbook: Magnesium and magnesium alloys, ASM International, Materials Park, OH (1999).

H. Chen, H. Yu, S. B. Kang, G. Min and Y. Jin, Effect of forming process on microstructure and mechanical properties of ZK60 alloy sheet, Rare Metal Mat. Eng., 40(10) (2011) 1708–1712.

D. Orlov, G. Raab, T. T. Lamark, M. Popov and Y. Estrin, Improvement of mechanical properties of magnesium alloy ZK60 by integrated extrusion and equal channel angular pressing, Acta. Mater., 59 (2011) 375–385.

R. Lapovok, P. F. Thomson and R. Cottam, The effect of grain refinement by warm equal channel angular extrusion on room temperature twinning in magnesium alloy ZK60, J. Mater. Sci., 40 (2005) 1699–1708.

R. Lapovok, P. F. Thomson, R. Cottam and Y. Estrin, The effect of warm equal channel angular extrusion on ductility and twinning in magnesium alloy ZK60, Mater. Trans., 45(7) (2004) 2192–2199.

S. M. He, L. M. Peng, X. Q. Zeng, W. J. Ding and Y. P. Zhu, Comparison of the microstructure and mechanical properties of a ZK60 alloy with and without 1.3 wt.% gadolinium addition, Mat. Sci. Eng. A, 433 (2006) 175–181.

J. Zhang, X. Zhang, W. Li, F. Pan and Z. Guo, Partition of Er among the constituent phases and the yield phenomenon in a semi-continuously cast Mg-Zn-Zr alloy, Scripta Mater., 63 (2010) 367–370.

T. Liu, F. Pan and Z. Zhang, Effect of Sc addition on the work-hardening behavior of ZK60 magnesium alloy, Mater. Design, 43 (2013) 572–577.

N. Ogawa, M. Shiomi and K. Osakada, Forming limit of magnesium alloy at elevated temperatures for precision forging, Int. J. Mach. Tool Manu., 42 (2002) 607–614.

C. Y. Wang, X. J. Wang, H. Chang, K. Wu and M. Y. Zheng, Processing maps for hot working of ZK60 magnesium alloy, Mat. Sci. Eng. A, 464 (2007) 52–58.

K. H. Jung, Y. B. Kim, B. Ahn, S. Lee, J. Lee, D. S. Choi and G. A. Lee, Workability of ZK60A alloy depending on microstructure, Appl. Mech. Mater., 217–219 (2012) 373–376.

F. C. Campbell, Elements of metallurgy and engineering alloys, ASM International, Materials Park, OH (2008).

G. V. Voort, Metallography of magnesium and its alloys, TECH-NOTES, Buehler GmbH, 4 (2). http://www.buehlerasia.com/brochure/apps_support-tech-notes_vol4iss2-tn42.pdf.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Dae-Cheol Ko

Ki-Ho Jung received B.E. from Korea Univ. and Ph. D. from KAIST in 2012. Since 2012, he has been a senior researcher at KITECH. His research interest includes forging process of magnesium alloy, sheet-bulk forging, and friction in meso µ forming.

Rights and permissions

About this article

Cite this article

Jung, K.H., Lee, S., Kim, Y.B. et al. Assessment of ZK60A magnesium billets for forging depending on casting methods by upsetting and tomography. J Mech Sci Technol 27, 3149–3153 (2013). https://doi.org/10.1007/s12206-013-0835-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-013-0835-y