Abstract

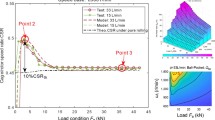

Skidding, which occurs in rolling element bearings during shaft rotational acceleration, causes wear and incipient failure. This paper presents an analytical model to investigate skidding during rolling element bearing acceleration, taking account of the contact force and friction force between the rolling elements and the races and the cage, gravity, and the centrifugal force of the rolling elements. The Hertzian contact theory is applied to calculate the non-linear contact force. The Coulomb friction law is used to calculate the friction force. All forces above are included in force equilibrium equations to derive the non-linear governing equations of the bearing during acceleration, and are solved using a fourth-order Runge-Kutta algorithm with fixed time step. The proposed model is verified by comparison to other published results and with experimental results. The proposed model can be used to investigate skidding in rolling element bearings during acceleration and the transient motion behavior of rolling elements, and it will lay the theoretical foundations for eliminating skidding in rolling element bearings.

Similar content being viewed by others

References

A. B. Jones, Ball motion and sliding friction in ball bearing, ASME Trans., 81 (1959) 1–12.

A. B. Jones, A general theory for elastically constrained ball and roller bearings under arbitrary load and speed conditions, ASME Trans., 82 (1960) 309–320.

T. A. Harris, Ball motion in thrust-load angular contact bearings with coulomb friction, Journal of Lubrication Technology, Transactions of the ASME, 95 (1971) 32–38.

T. A. Harris, An analytical model to predict skidding in thrust-loaded, angular-contact ball bearings, Journal of Lubrication Technology, Transactions of the ASME, 93 (1971) 17–24.

T. A. Harris, An analytical model to predict skidding in high speed roller bearings, ASME Trans., 9 (1966) 229–241.

C. T. Walters, The dynamics of ball bearings, Journal of Lubrication Technology, 93 (1971) 1–10.

P. K. Gupta, Transient ball motion and skid in ball bearings, Journal of Lubrication Technology (1975) 261–269.

T. A. Harris and K. MichealN, Rolling bearing analysisessential concepts of bearing technology, 5th Ed. Taylor and Francis; (2007).

F. Hirano, Motion of a ball in angular-contact ball bearing, ASLE Trans., 8 (1965) 425–434.

N. T. Liao and L. F. Lin, Ball bearing skidding under radial and axial loads, Mechanism and Machine Theory, 37 (2002) 91–113.

A. Selvaraj and R. Marappan, Experimental analysis of factors influencing the cage slip in cylindrical roller bearing, Inv J Adv Manuf Technol (2010).

S. Andersson, A. Soderberg and S. Bjorklund, Friction models for sliding dry, boundary and mixed lubricated contacts, Tribology International, 40 (2007) 580–587.

E. Laniado-Jacome, J. Meneses-Alonso and V. Diaz-Lopez, A study of sliding between rollers and races in a roller bearing with a numerical model for mechanical event simulations. Tribology International (2010).

S. Jain and H. Hunt, A dynamic model to predict the occurrence of skidding in wind-turbine bearings, 9th International Conference on Damage Assessment of Structures (2011).

N. Ghaisas, C. R. Wassgren and F. Sadeghi, Cage instabilities in cylindrical roller bearing, Journal of Tribology, 126 (2004) 681–689.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Ohseop Song

Wenbing Tu, born in 1983, is currently a Ph.D student of Chongqing University, People’s Republic of China. He conducts research in the areas of structural dynamics and numerical simulation, vibration and noise of mechanical system.

Yimin Shao is a full Professor in the State Key Laboratory of Mechanical Transmission at Chongqing University, Chongqing, China. His research interests include machine dynamic analysis, vibration analysis, signal processing and on-line machinery condition monitoring and fault diagnosis system.

Chris K. Mechefske is a full Professor in the Department of Mechanical and Materials Engineering at Queen’s University in Kingston, Ontario, Canada. His research interests include vibration based machine condition monitoring and fault diagnostics, maintenance and reliability, machine dynamic analysis, biomechanics of artificial limbs, vibration and noise reduction in and around biomedical equipment. He is a member of the editorial board of the Journal of Condition Monitoring and Diagnostic Engineering Management; Canadian Advisory Council, ISO Technical Committee 108, Sub-Committee 5; American Society of Mechanical Engineers; Canadian Machinery Vibration Association (past president 2003–2005); and the International Institute of Acoustics and Vibration (Director 2007–2009).

Rights and permissions

About this article

Cite this article

Tu, W., Shao, Y. & Mechefske, C.K. An analytical model to investigate skidding in rolling element bearings during acceleration. J Mech Sci Technol 26, 2451–2458 (2012). https://doi.org/10.1007/s12206-012-0627-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-012-0627-9