Abstract

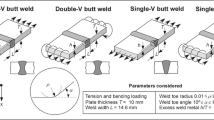

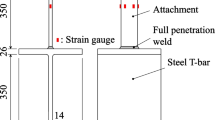

To effectively calculate the stress intensity factors in welded components, a weld toe magnification factor is introduced here that will allow for the influence of geometrical effects. This factor was derived from the data obtained in a parametric study performed by FEM. Several sets of weld toe magnification factor solutions have been presented, but these are applicable only to non-load-carrying cruciform or T-butt joints, due possibly to the requirement of very complicated calculations. In the majority of cases for various welded joints such as cruciform, cover plate and longitudinal stiffener joints, the currently used weld toe magnification factors do not adequately describe the behavior of weld toe cracks. In the present study, the weld toe magnification factor solutions with exponents and fractions that have polynomial functions in terms of a/c and a/t — i.e., crack depths normalized by corresponding crack lengths and specimen thickness — were developed through a parametric study using 3-dimensional finite elements for the above mentioned three types of welded joints. These weld toe magnification factor solutions showed a tendency to increase at a/t < 0.2. Meanwhile, for 0.2 < a/t < 0.7, the effect of the attachment on the weld toe magnification factor decreased asymptotically. When the a/t ratio exceeded this range, the weld toe magnification factor became almost one of unity. The fatigue crack propagation life was evaluated by using the proposed weld toe magnification factor and by considering the propagation mechanisms of multiple-surface cracks, and it showed good agreement-to within a deviation factor of 2-between the experimental and calculated results for the fatigue crack propagation life for all welded joint.

Similar content being viewed by others

References

C. Suh, N. Hwang and M. Park, Fatigue crack growth, coalescence behavior and its simulation on multi-surface cracks, Transactions of the Korean Society of Mechanical Engineers, 18(3) (1994) 716–728.

D. Browness and M. Lee, Prediction of weld toe magnification factors for semi-elliptical cracks in T-butt joints, International Journal of Fatigue, 22 (2000) 369–387.

R. Bell and K. Kirkhope, Stress intensity factors for single and multiple semi-elliptical surface cracks in pressurized thick-walled cylinders, International Journal of Pressure Vessels and Piping, 47(2) (1991) 247–257.

BS7910, Guide on methods for assessing the acceptability of flaws in metallic structures, British Standard Institute (1999).

S. T. Lie, Z. Zhao and S. H. Yan, Two-dimensional and three-dimensional magnification factors, Mk, for non-load-carrying fillet welds cruciform joints, Engineering Fracture Mechanics, 65 (2000) 435–453.

J. Han, S. Han, B. Shin and J. Kim, Fatigue crack initiation and propagation life of welded joints, Key Engineering Materials, 297 (2006) 781–787.

R. Yuuki and T. Yoshida, Fatigue life prediction system for structures, Journal of High Pressure Institute, 24(3) (1986) 115–123.

T. Fett, An extension of the Newman-Raju formula, International Journal of Fracture, 33 (1987) 47–50.

JSSC, Guideline of Fatigue Design in Steel Construction, Japan Society of Steel Construction (1993).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Dong-Ho Bae

Jeong-Woo Han received his B.S. and M.S. degrees in Mechanical Engineering from Inha University, Korea, in 1992 and 1994, respectively. He then received his Ph.D in Mechanical Design Engineering from Chungnam National University, Korea, in 2005. Dr. Han is currently a principal researcher at the Dept. of System Reliability of Korea Institute of Machinery & Materials in Daejeon, Korea. His research interests are in structural safety and experimental fatigue strength assessment.

Rights and permissions

About this article

Cite this article

Han, JW., Lee, KH. & Han, SH. Three-dimensional weld toe magnification factors for various welded joints. J Mech Sci Technol 26, 2121–2124 (2012). https://doi.org/10.1007/s12206-012-0527-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-012-0527-z