Abstract

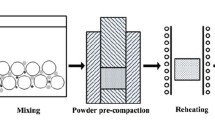

Aluminum alloy matrix composites reinforced with SiC particles (AMC) are potential materials applicable to weight reduction of friction materials. We developed two AMC: A356/SiC and A390/SiC. 30 μm and 60 μm SiC particles with volume fraction of 20% were dispersed in the matrix of A356 and A390 alloys. When the temperature of the liquid alloy was higher than that of the melting point, SIC particles floated up to the surface because of the low viscosity, high surface tension and interfacial energy. To mix the ceramic particles, the aluminum alloy was in the mushy state near the solidus temperature, 610°C for A356 and 645°C for A390. Metallurgical, mechanical and tribological characteristics of the manufactured composites were evaluated.

Similar content being viewed by others

References

T. Tsujimura, K. Takao, A. Watanabe and E. Nishii, Development of aluminum alloy composite brake disc for rolling stocks, QR of RTRI, 36(3) (1995) 149–154.

K. Laden, J. D. Guerin, M. Watremez and J. P. Bricout, Frictional characteristics of Al-SiC composite brake discs, Tribology Letters, 8 (2000) 237–247.

H. Nakanishi, K. Kakihara, A. Nakayama and T. Murayama, Development of aluminum metal matrix composites (Al-MMC) brake rotor and pad, JSAE Review, 3 (2002) 365–370.

R. K. Uyyuru, M. K. Surappa and S. Brusethaug, Effect of reinforcement volume fraction and size distribution on the tribological behavior of Al-composite/brake pad tribo-couple, Wear, 260(11–12) (2006) 1248–1255.

J. Han, Z. Sha, W. Li, S. Cui and J. Wang, Research on the method for producing complex SiCp/Al composite disk brake castings, Journal of Ceramic Processing Research, 7(4) (2006) 339–342.

S. Zhang and F. Wang, Comparison of friction and wear performances of brake material dry sliding against two aluminum matrix composites reinforced with different SiC particles, Journal of Materials Processing Technology, 182(1–3) (2007) 122–127.

A. Daoud and M. T. Abou El-khair, Wear and friction behavior of sand cast brake rotor made of A359-20 vol% SiC particle composites sliding against automobile friction material, Tribology International, 43(3) (2010) 544–553.

D. Gultekin, M. Uysal, S. Aslan, M. Alaf, M. O. Guler and H. Akbulut, The effects of applied load on the coefficient of friction in Cu-MMC brake pad/Al-SiCp MMC brake disc system, Wear, 270(1–2) (2010) 73–82.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Dong-Ho Bae

Byeong-choon Goo, who received his Ph.D. from the University of Franche-Comté, France, has been a principal researcher at Korea Railroad Research Institute since 1996. His main research area includes brake system, brake squeal noise, structural analysis, wheel/rail contact, fatigue, and shape memory alloy.

Rights and permissions

About this article

Cite this article

Goo, BC., Kim, MH. Characteristics of A356/SiCp and A390/SiCp composites. J Mech Sci Technol 26, 2097–2100 (2012). https://doi.org/10.1007/s12206-012-0522-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-012-0522-4