Abstract

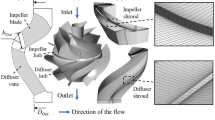

In the present study, the hydrodynamic characteristics of the Maxblend impeller have been investigated. A commercial CFD package (CFX 12.0) was used to solve the 3D hydrodynamics and to characterize the flow patterns at every point. A shear thinning fluid with yield stress was modeled in the laminar regime and transition regime. The study focused on the effect of fluid rheology, agitator speed, impeller clearance from the tank bottom and blade size on the fluid flow and power consumption. Predictions have been compared with literature data and a satisfactory agreement has been found.

Similar content being viewed by others

References

P. M. Armenante, C. Luo, C. C. Chou, I. Fort and J. Medek, Velocity profiles in a closed, unbaffled vessel: comparison between experimental LDV data and numerical CFD prediction, Chem. Eng. Sci. 52(20) (1997) 3483–3492.

A. K. Sahu, P. Kummar and J. B. Joshi, Simulation of flow in stirred vessels with axial flow impellers: zonal modeling and optimization of parameter, Ind. Eng. Chem. Res. 37(6) (1998) 2116–2130.

M. Sommerfeld and S. Decker, State of the art and future trends in CFD simulation of stirred vessel hydrodynamics, Chem. Eng. Tech. 27(3) (2004) 215–224.

Sumitomo Heavy Industries, available at http://www.shi.co.jp/maxblendclub/e-index.html.

T. Kouda, H. Yano and F. Yoshinaga, Effect of agitator configuration on bacterial cellulose productivity in aerated and agitated culture, J. Ferm. Bioeng. 83(2) (1997) 371–376.

O. Hiruta, K. Yamamura, H. Takebe, T. Futamura, K. Iinuma and H. Tanaka, Application of Maxblend fermentor for microbial processes, J. Ferm. Bioeng. 83(1) (1997) 79–86.

Y. Sumi and M. Kamiwano, Development and mixing characteristic of multistage impeller for agitating highly viscous fluid, Chem. Eng. Jpn. 34(4) (2001) 485–492.

W. Yao, M. Mishima and K. Takahashi, Numerical investigation on dispersive mixing characteristics of Maxblend and double helical ribbons, Chem. Eng. J. 84(3) (2001) 565–571.

N. Dohi, T. Takahashi, K. Minekawa and Y. Kawase, Power consumption and solid suspension performance of largescale impellers in gas-liquid-solid three-phase stirred tank reactors, Chem. Eng. J. 97(3) (2004) 103–114.

K. Takahashi, H. Horiguchi, M. Mishima and R. Yatomi, Mixing characteristics in a vessel agitated by large paddle impeller Maxblend, Proc. of 12th European Conference on Mixing, Bologna, Italy (2006).

T. Takahashi, A. Tagawa, N. Atsumi, N. Dohi and Y. Kawase, Liquid phase mixing time in boiling stirred tank reactors with large cross-section impellers, Chem. Eng. Proc. 45(4) (2006) 303–311.

A. Iranshahi, C. Devals, M. Heniche, L. Fradette, P. A. Tanguy and K. Takenaka, Hydrodynamics characterization of the Maxblend impeller, Chem. Eng. Sci. 62(4) (2007) 3641–3653.

L. Fradette, G. Thome, P. A. Tanguy and K. Takenaka, Power and mixing time study involving a Maxblend impeller with viscous Newtonian and non Newtonian fluids, Chem. Eng. Res. Des. 85(11) (2007) 1514–1523.

C. Devals, M. Heniche, K. Takenaka and P. A. Tanguy, CFD analysis of several design parameters affecting the performance of the Maxblend impeller, Comp. Chem. Eng. 32(8) (2008) 1831–1841.

D. Patel, F. Ein-Mozaffari and M. Mehrvar, Improving the dynamic performance of continuous-flow mixing of pseudoplastic fluids possessing yield stress using Maxblend impeller, Chem. Eng. Res. Des. 90(4) (2011) 514–523.

C. A. Rivera, M. Heniche, K. laminar and transition flow of Chem. Eng. Sci. 64(21) (2009) 4442–4456.

J. Aubin, I. Naude, C. Xuereb and J. Bertrand, Blending of Newtonian and shear-thinning fluids in a tank stirred with a helical screw agitator, Trans. Inst. Chem. Eng. 78(4) (2000) 1105–1114.

I. Naude, Direct simulations of impellers in a stirred tank: Contribution to the optimization of the choice of an agitator, Ph.D. thesis, INPT, France (1998).

B. Letellier, C. Xuereb, P. Swaels, P. Hobbes and J. Bertrand, Scale-up in laminar and transient regimes of a multistage stirrer, a CFD approach, Chem. Eng. Sci. 57(21) (2002) 4617–4632.

V. Buwa, A. Dewan, A. F. Nasser and F. Durst, Fluid dynamics and mixing of single-phase flow in a stirred vessel with a grid disc impeller: experimental and numerical investigations, Chem. Eng. Sci. 61(9) (2006) 2815–2822.

C. W. Macosko, Rheology: Principles, measurements & applications, Wiley-VCH, New York (1994).

B. Metzner and R. E. Otto, Agitation of non-Newtonian fluids, AIChE J. 3(1) (1957) 3–11.

E. Galindo and A. W. Nienow, The performance of the Scaba 6SRGT agitator in the mixing of simulated xanthan gum broths, Chem. Eng. Technol. 16(2) (1993) 102–108.

L. Pakzad, F. Ein-Mozaffari and P. Chan, Using computational fluid dynamics modeling to study the mixing of pseudoplastic fluids with a Scaba 6SRGT impeller, Chem. Eng. and Proc. 47(12) (2007) 2218–2227.

L. W. Adams and M. Barigou, CFD analysis of caverns and pseudo-caverns developed during mixing of non-Newtonians fluids, Chem. Eng. Res. Des. 85(5) (2007) 598–604.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Byeong Rog Shin.

Houari Ameur was born in 1982 in Tlemcen, Algeria. He received his degree of engineer in marine engineering and master in mechanical engineering at the University of Science and Technology, Oran, Algeria. He is a Ph.D student in rheology of complex fluids. His current research interests are mainly in the area of non-Newtonian fluid flows, mechanical mixing and computational fluid dynamics.

Rights and permissions

About this article

Cite this article

Ameur, H., Bouzit, M. & Helmaoui, M. Hydrodynamic study involving a maxblend impeller with yield stress fluids. J Mech Sci Technol 26, 1523–1530 (2012). https://doi.org/10.1007/s12206-012-0337-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-012-0337-3