Abstract

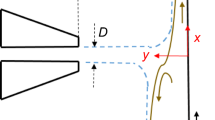

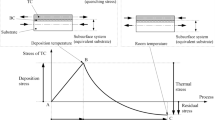

It is known that the distributions of the impinging pressure gradient and the shear stress at the strip surface play a decisive key role in the decision of the coating thickness in hot-dip galvanizing. So, to predict the exact coating thickness, it is essential that the distributions of the impinging wall jet pressure and the shear stress acting between the liquid film and jet stream are measured (or calculated) exactly for each specific coating condition. So far, to obtain the impinging wall jet pressure, it was assumed that the jet issuing from an air-knife is similar to the Hiemenz plane stagnation flow, and the wall shear stress could be predicted by an equation using the assumption of a non-negative Gaussian profile in impinging wall jet pressure in general, so that it cannot be reliable for some impinging wall jet regions and nozzle systems intrinsically. Nevertheless, one cannot find a suitable method to cope with the difficulties in measuring/calculating of the shear stress and the impinging wall jet pressure. Such a difficulty which will cause an inaccuracy in the coating thickness prediction. With these connections, in the present study, we suggest a new method named as a two-step calculation method to calculate the final coating thickness, which consists of the air jet analysis and coating thickness calculation. And, from the comparison of the results one may confirm the validation of the new suggested method.

Similar content being viewed by others

References

J. A. Thornton and H.F. Graff, An analytical description of the jet finishing process for hot-dip metallic coatings on strip, Metallurgical Trans. B, 7B (1976) 607–618.

S. Umeda, K. Hara, T. Yamaguchi, Y. Imai and K. Ebara, Continuous galvanizing line for mild steel strip, UDC, 621,795,5,06-932,2:669,58.

C. V. Tu and D. H. Wood, Wall pressure and shear stress measurements beneath an impinging jet, Experimental Thermal and Fluid Science, 13 (1996) 364–373.

T. Hara, T. Adaniya, M. Yamashita, Y. Tajiri and M. Ogawa, Development of a new gas wiping process for high-speed chemical treatment, Iron and Steel, 105 (1984) 90–97.

C. H. Ellen and C. V. Tu, An analysis of jet stripping of liquid coatings, J. of Fluids Eng., 106 (1984) 399–404.

H. Schlichting, Boundary layer theory, 7th ed. Mcgraw-Hill, pp. 95–110.

S. Beltaos, Oblique impingement of plane turbulent jets, J. of the Hydraulics Division (1976) 1177–1192.

Y. Takeishi, A. Yamauchi and S. Miyauchi, Gas wiping mechanism in hot-dip coating process, Iron and Steel, 81(6) (1995) 643–648.

M. Dubois, J. M. Buchlin, A. Gosset and V. Perrot, Effect of nozzle tilting on splashing in jet wiping, Galvatech’04 Conf. Prc., pp. 197–120.

Y. Takeishi, Y. Suzuki and K. Yabuki, Mechanism and prevention of splashing from strip edge in gas wiping process for continuous hot-dip coating, Japanese J. Multiphase Flow, 14(2) (2000) 194–202.

Kurabo Electronics Division, Infrared Thickness Meter RX-210.

POSCO Technical Research Laboratories 699, Gumhodong, Gwangyang Jeonnam 545-090, Korea.

J. Senter and C. Soliec, Flow field analysis of a turbulent slot air jet impinging on a moving flat surface, Int. J. Heat and Fluid Flow, 28 (2007) 708–719.

S. B. Kwon, Y. D. Kwon, S. J. Lee, S. Y. Shin and G. Y. Kim, Numerical analysis for the coating thickness prediction in continuous hot-dip galvanizing, J. of Mechanical Science and Technology, 23 (2009) 3471–3478.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Simon Song

Soon-Bum Kwon received his B.S. and M.S. degrees in Mechanical Engineering from Kyungpook National University in 1974 and 1980, respectively, and his Ph.D degree from Kyushu University in 1987. He is a Professor at the school of Mechanical Engineering at Kyungpook National University, Korea. His research interests are compressible gas dynamics and nonequlibrium condensation.

Rights and permissions

About this article

Cite this article

Jo, C.M., Kim, G.Y., Kwon, Y.D. et al. A suggestion of a new method for the calculation of the coating thickness in continuous hot-dip galvanizing. J Mech Sci Technol 25, 2781–2786 (2011). https://doi.org/10.1007/s12206-011-0907-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-011-0907-9