Abstract

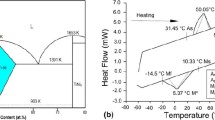

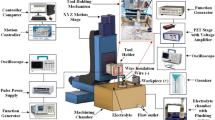

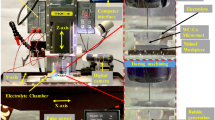

Nitinol, a shape memory alloy (SMA), is manufactured from titanium and nickel, and is employed in various fields for use in devices such as micro sensors, ultra-precision devices and satellite wings. It is also highly recommended as a material in medical stents for insertion into the human body because it has excellent organic compatibility. However, because they are intended to be inserted into the human body, products such as medical stents require a high-quality surface. Because nitinol has more of the characteristics of titanium than of nickel, one of its drawbacks is that heat generated in nitinol during machining is not discharged smoothly and inner stress occurs when traditional machining methods are used. To overcome this difficulty, various non-traditional machining methods, including non-contact machining, have been investigated for use with nitinol. To further explore non-traditional machining methods that may be appropriate for use with nitinol, this study investigates the application of electrochemical polishing to the machining of nitinol. Characteristics of the electrochemical polishing (EP), a representative non-traditional machining, for nitinol SMA are studied. Nitinol SMA of the EP machining parameters such as electrolyte composition, applied current, machining time and inter electrode gap (IEG) are researched and the machined surface state is analyzed according to each parameters parameter. So, the most suitable EP machining conditions for nitinol SMA are derived.

Similar content being viewed by others

References

I. Roy and M. N. Gupta, Smart polymeric materials: emerging biochemical applications, Chemistry & Biology, 10(12) (2003) 1161–1171.

A. B. Flatau and K. P. Chong, Dynamic smart material and structural systems, Engineering Structures, 24(3) (2002) 261–270.

R. Mukherjee, T. F. Christian and R. A. Thiel, An actuation system for control multiple shape memory alloy actuator, Sensor and Actuators A:physics, 55 (1996) 185–192.

M. J. Shin, S. Y. Baek and E. S. Lee, A study for improving surface roughness and micro-deburring effect of nitinol shape memory alloy by electropolishing, Transactions of the Korean Society of Machine Tool Engineers,16(6) (2007) 49–54.

R. Schuster, V. Kirchner, P. Allongue and G. Ertl, Electrochemical Micromachining, Science, 289 (2000) 98–101.

P. S. Pa, Design of continuity processes of electrochemical finishing and grinding following turning, Journal of Mechanical Science and Technology, 22(11) (2008) 2197–2202.

W. M. Kim, A study on the development of the electrolytic-deburring system and characteristics of the micro deburring, Graduate Thesis of In-ha Univ. (2006).

E. S. Lee, J. W. Park and Y. H. Moon, Development of Ultra Clean Machining Technology with Electrolytic Polishing Process, International Journal of the Korean Society of Precision Engineering, 2(1) (2001) 18–25.

T. Hryniewicz, Towards a new conception of electropolishing of metals and alloys, Proceedings of First East-West Symposium on Materials and Processes, UK, 243–252 (1990).

K. Fushimi, M. Stratmann and A. W. Hassel, Electropolishing of NiTi shape memory alloys in methanolic H2SO4, Electrochimica Acta, 52(3) (2006) 1290–1295.

X. Z. Ma, L. Zhang, G. H. Cao, Y. Lin and J. Tang, Electrochemical micromachining of nitinol by confined-etchantlayer technique, Electrochimica Acta, 52(12) (2007) 4191–4196.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor In-Ha Sung

Eun Sang Lee received B.S. and M.S. degrees in Mechanical Engineering from INHA University in 1985 and in 1987. Dr. Lee received a Ph.D. from the Korea Advanced Institute of Science and Technology in 1998. Dr. Lee is currently a Professor at the School of Mechanical Engineering at INHA University in Incheon, Korea. His research fields are in ultra-precision manufacturing, electrochemical micromachining and the development of a semiconductor wafer polishing system.

Rights and permissions

About this article

Cite this article

Lee, E.S., Shin, T.H. An evaluation of the machinability of nitinol shape memory alloy by electrochemical polishing. J Mech Sci Technol 25, 963–969 (2011). https://doi.org/10.1007/s12206-011-0209-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-011-0209-2