Abstract

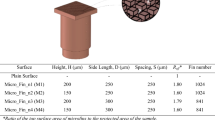

The temperature uniformity on a heat pipe hot chuck (HPHC) during semiconductor wafer processing has been an important factor to critical dimension (300 mm) uniformity as the feature size of semiconductors decreases and productivity density increases due to the new process of nano size special manufacturing technology. To design the present heat pipe hot chuck system, which has enhanced temperature uniformity for the wafer process, the heat distribution of the system was analyzed experimentally with various working fluids such as water, TiO2, ATO, ITO, Al2O3, and Ag-nanofluids and 8 cell structures. Unlike the conventional solid state chuck, the present heat pipe hot chuck system consists of a heat pipe containing specially charged working fluid. Various working fluids have been tested to find best temperature uniformity feature on the top surface of hot chuck. TiO2-nanofluid was used and tested as the working fluid of the heat pipe hot chuck system in this paper. The temperature uniformity of upper surface was sustained in the range of ±1°C. A nano-porous layer was observed on the surface with the good result of surface temperature uniformity compared with distilled water.

Similar content being viewed by others

References

Y. Hisaaki and O. Tetsuro, Development of Heat Pipe Isothermal Heating Plate, Proceeding of 8 th IHPS, Kumamoto, Japan, (2006).

Q. Zhang, P. Friedberg, K. Poolla and C. Spanos, Enhanced Spatial PEB Uniformity through a Novel Bake Plate Design, AEC/APC XVII 2005, (2006).

Q. Zhang, P. Friedberg et al., Across Wafer CD Uniformity Enhancement through Control of Multi-zone PEB Profiles, Metrology, Inspection, and Process Control for Microlithography XVIII, SPIE 5375, (2004).

P. Friedberg, C. Tang et al., Time-based PEB adjustment for optimizing CD distributions, Metrology, Inspection, and Process Control for Microlithography XVIII, SPIE 5375, (2004).

D. Steele, A. Coniglio et al, Characterizing Post Exposure Bake Processing for Transient and Steady State Conditions, in the Context of Critical Dimension Control, Metrology, Inspection, and Process Control for Microlithography XVI, SPIE 5375, (2002).

D. R. FLYNN, W. M. HEALY and R. P. ZARR, High-Temperature Guarded Hot Plate Apparatus: Optimal Locations of Circular Heaters, International Thermal Conductivity 28th Conference/International Thermal Expansion 16th Symposium. Proceedings, June 26–29, New Brunswick, Canada, (2005) 466–477.

G. J. Park, J. O. Yang, H. S. Kwak, S. H. Park and J. J. Lee, Design and Experimental Test of a Hot Plate for Hot Embossing Nano-Imprintting Equipments, Proceeding of KSME Annual Spring & Fall Meeting, (2006) 2006–2011.

G. J. Park, H. S. Kwak, D. W. Shin and J. J. Lee, Numerical simulation of thermal control of a hot plate for thermal nanoimprint lithography machines, Proceeding of KSCFE Annual Fall Meeting, (2007) 153–158.

S. Y. Lee, H. H. Cho, Y. W. Lee and Lee, A study to improve Temperature Uniformity in Hot plate Oven for Silicon Wafer Manufacturing, Journal of the KSME (B), 2(2) (2000) 261–266.

J. Lee and H. H. Cho, Study on Thermal Design of Hot Plate for Enhancing Temperature Uniformity, KSME Annual Fall Meeting, (2007) 190–194.

G. J Park, J. O. Yang, H. S. Kwak and J. J. Lee, Employment of heat pipes to achieve temperature uniformity of a large-area hot-plate for TH-NIL, KSMTE Annual Fall Meeting, (2007) 74–79.

J. H. Boo, W. B. Chung, T. G. Kim, study on the Condenser Temperature Characteristics of a Disk Type Heat Pipe, KSME Fall Conference, (2000) 148–153.

Y. Lee, I. L. Pioro and H. J. Park, An Experimental Study on a Plate Type Two-Phase Closed Thermosyphon, 4 th IHPS, Tsukuba, Japan, (1994) 49–58.

H. Imura, K. Sasaguchi and H. Kozai, Critical Heat Flux in a Two Phase Closed Thermosyphon,” Int. J. of Heat Transfer, 26(8) (1993) 1181–1188.

S. J. Kim, I. C. Bang, J. Buongiorno and L. W. Hub, Surface wettability change during pool boiling of nanofluids and its effect on critical heat flux, Int. J. of Heat and Mass Transfer, 50(19–20) (2007) 4105–4116.

S. U. S. Choi, Enhancing thermal conductivity of fluids with nanoparticles, in Developments and Applications of Non-Newtonian Flows, ASME FED 231/MD 66 (1995) 99–103.

S. K. Das, N. Putra and W. Roetzel, Pool boiling characterization of nano-fluids, International Journal of Heat and Mass Transfer, 46 (2003) 851–862.

S. K. Das, N. Putra and W. Roetzel, Pool boiling nanofluids on horizontal narrow tubes, International Journal of Multiphase Flow, 29 (2003) 1237–1247.

H. T. Chien, C. I., Tsai, P. H., Chen and P.-Y. Chen, Improvement on thermal performance of a disk shaped miniature heat pipe with nanofluid, IEEE ICEPTD, (2003) 381–391.

C. Y. Tsai, H. T. Chien, P. P. Ding, B. Chan, T. Y. Luh and P. H. Chen, Effect of structural character of gold nanoparticles in nanofluid on heat pipe thermal performance, Materials Letters, 58 (2004) 1461–1465.

S. W. Kang, W. C. Wei, S. H. Tsai and S. Y. Yang, Experimental investigation of silver nano-fluid on heat pipe thermal performance, Applied Thermal Engineering, 26 (2006) 2377–2382.

H. B. Ma, S. U. S. Choi and M. Tirumala, Effect of nanofluid on the heat transport capability in an oscillating heat pipe, Applied Physics Letters, 88 (2006) 116–143.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Dongsik Kim

Taek-Kyu Lim is a graduate student in the School of Mechanical Engineering, Chungbuk National University. He is working on heat pipe systems, CFD and heat exchangers.

Seok-Ho Rhi is an Associate Professor in Chungbuk National University and he received the Ph.D degree from the University of Ottawa, Canada. He is interested in heat pipes, heat exchangers and, thermoelectric modules.

Rights and permissions

About this article

Cite this article

Lim, TK., Rhi, SH. Experimental study on nanofludic heat pipe hot chuck plate in semiconductor wafer baking process. J Mech Sci Technol 24, 1501–1509 (2010). https://doi.org/10.1007/s12206-010-0501-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-010-0501-6