Abstract

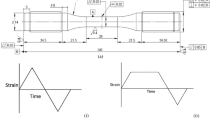

Super-heater tubes are subjected to alternate heating and cooling in power plants causing them to crack and eventually fail. This phenomenon is referred to as “thermal fatigue.” In this paper, a laboratory simulation for reproducing the thermal fatigue phenomenon is developed to determine the number of cycles necessary before failure occurs in super-heater tubes. The temperature and strain distributions along the specimen were computed theoretically using ANSYS software for the applied temperature condition. The thermal fatigue test was conducted for both base and shielded metal arc (SMA) welded tubes separately and both passed in the non-destructive tests. These tubes were subjected to thermal cycles from 800°C (accelerated temperature) to room temperature. Oxy-acetylene heating setup was utilized as a heating source, and a water bath was utilized for quenching purposes. The tests were carried out until open cracks were identified. Surface cracks were identified in the base and weld tubes after 90 and 60 cycles respectively. This study reveals that heating and cooling cause thermal fatigue, initiate cracks in the tubes.

Similar content being viewed by others

References

M. Hayashi, Thermal fatigue behavior of thin-walled cylindrical carbon steel specimens in simulated BWR environment, International Journal of Nuclear Engineering and Design, 184 (1998) 123–133.

T. Yoshimoto, S. Ishihara, T. Goshima, A. J. McEvily and T. Ishizaki, An improved method for the determination of the maximum thermal stress induced during a quench test, Scripta Materialia, 41(5) (1999) 553–559.

A. Tulyakov, Thermal fatigue in heat power engineering, Mashinostroyeniye, 197 (1978).

A. B. Vainman, R. K. Melekhov and O. D. Smiyan, Hydrogen induced embitterment of high- pressure boiler elements. Kyiv, Naukova Dumka, 272 (1990).

Virkkunen Iikka, Thermal fatigue of austenitic and duplex stainless steels. Acta Polytechnica Scandinavica, Published by the Finnish Academies of Technology Mechanical Engineering Series No. 154 Espoo (2001) 115.

B. B. Kerezsi, J. W. H. Price and R. N. Ibrahim, Using S-N curves to analyse cracking due to repeated thermal shock, Journal of Materials Processing Technology, 145 (2004) 118–125.

H. C. Young and Y. C. Sun, Socket weld integrity in nuclear piping under fatigue loading condition, Nuclear Engineering and Design, 237 (2007) 213–218.

A. Usman and A. Nusair Khan, Failure analysis of heat exchanger tubes, Engineering Failure Analysis, 15 (2007) 118–128.

A. Shiblia and F. Starr, Some aspects of plant and research experience in the use of new high strength martensitic steel T91, International Journal of Pressure Vessels and Piping, 84 (2007) 114–122.

T. B. Brown, Assessing the effect of thermal transients on the life of boiler plant, Babcock Energy Limited, Scotland (1998).

J. P King and D. B. Riley, Inc. Worcester, Massachusetts, Recent experience in condition assessments of boiler header components and supports, Presented at the 1996 ASME Pressure Vessels and Piping Conference, (1996) July 21–26.

I. R. Paterson and J. D. Wilson, Use of damage monitoring systems for component life optimization in power plant, International Journal of Pressure Vessels and Piping, 79 (2002) 541–547.

T. Tokiyoshi, F. Kawashima, T. Isari and H. Kino, Crack propagation life prediction of a perforated plate under thermal, International Journal of Pressure Vessels and Piping, 78 (2001) 837–845.

B. B. Kerezsi, A. G. Kotousov and J. W. H. Price, Experimental apparatus for thermal shock fatigue investigations, International Journal of Pressure Vessels and Piping, 77 (2000) 425–434.

B. J. Smith, C. I. Erskine, R. J. Hartranft and A. R. Marder, High-Temperature Corrosion-Fatigue (Circumferential) Cracking life Evaluation Procedure for low Alloy Cr-Mo) Boiler Tube Steels, Lehigh University, Bethlehem, PA 18025 (1999).

E. E. Underwood and K. S Banerji, Fractal analysis of fracture surfaces, ASM Hand Book, formerly Ninth edition, Metals Handbook, volume-12 (2000).

P. E Daniel J Benac and V. P. Swaminathan, Elevated-Temperature life assessment for turbine components piping and tubing failure analysis and prevention, ASM Handbook, volume 11.

V. J. Papazoglou and K. Masubuchi, Numerical analysis of thermal stresses during welding including phase transformation effects, Journal of Pressure Vessel Technology, 104(3) (1982) 198–203.

J. N. Reddy, On penalty function methods in the finite element analysis of flow problems, International Journal For Numerical Methods, 2(2) (1982) 151–171.

J. C Vailant, B. Vanderberghe and C. Zakine, The T23/ P23, T22/ P22, T91/ P91, T92/ P92, Book, Vallourec & Mannesmann tubes.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Dae-Eun Kim

P. Sathiya 2006 Doctoral Thesis on Friction welding of similar stainless steels and Evaluation of processed joints, Bharathidasan University, Tiruchirappalli, Tamilnadu, India. 1996 Master degree on Welding Engineering, Regional Engineering College, Bharathidasan University, Tiruchirappalli, Tamilnadu, India. 1994 Under graduate Degree on Mechanical Engineering, Government college of Engineering, Salem, University of Madras, Tamilnadu, India. Assistant Professor, Department of Production Engineering, National Institute of Technology, Tiruchirappalli, Tamilnadu, India. I am working in the area of Welding Technology, Solid state Joining, Materials Behaviour Subjected to Welding, Similar and Dissimilar Materials Welding, Failure Analysis of Weldments, Modeling, Simulation of Welding processes and Welding parameter optimization. I received young technology award 2009, from Indian Welding Society, India and also received young scientist award from Department of Science and Technology, New Delhi, India. Published thirty papers in international and national reputed journals.

Rights and permissions

About this article

Cite this article

Jinu, G.R., Sathiya, P., Ravichandran, G. et al. Comparison of thermal fatigue behaviour of ASTM A 213 grade T-92 base and weld tubes. J Mech Sci Technol 24, 1067–1076 (2010). https://doi.org/10.1007/s12206-010-0322-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-010-0322-7