Abstract

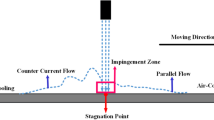

In this paper, an advanced temperature control for the high carbon steel is proposed to obtain the desirable temperature and property of a steel on the run-out table (ROT) process. The temperature model based on the nonlinear heat transfer equation is described to predict the temperature of the steel at each position of the ROT. A cooling stop temperature (CST) concept is proposed to increase the volume fraction of the transformed phase for the high carbon steel. The concept is derived from a time-temperature transformation (TTT) diagram which is measured from the dilatometric experiment. The simulator using the temperature model is developed to achieve the desired temperature, and the effectiveness of the proposed control is also analyzed from the simulation. It is shown through the field test of the hot strip mill of POSCO that the performance with respect to the temperature and the property of the steel is greatly improved by the proposed control technology.

Similar content being viewed by others

References

M. Phaniraj, S. Shamasundar and A. K. Lahiri, Relevance of ROT control for hot rolled low carbon steels, Steel Res., 72(5) (2001) 221–224.

W. Timm, K. Weinzierl, A. Leipertz, H. Zieger and G. Zouhar, Modelling of heat transfer in hot strip mill runout table cooling, Steel Res., 73(3) (2002) 97–104.

M. Suehiro, T. Oda, T. Senuma and S. Konishi, Development of mathematical model for predicting transformation of high-carbon steel during cooling on runout table and its application to on-line temperature control of hot strip mill, Nippon Steel Technical Report, 67 (1995) 49–56.

R. Xu, J. Liu, Y. Zhang, R. Guo and W. Liu, Transformation-induced plasticity of expandable tubulars materials, Materials Science and Eng. A 438-440 (SPEC. ISS.), (2006) 459–463.

T. Oda, Y. Kondo, S. Konishi, H. Murakami, M. Suehiro and T. Yabuta, Development of accurate temperature control in hot strip mill, The Iron and Steel Institute of Japan, 81(3) (1995) 35–40.

N. S. Samaras, Novel control structure for runout table coiling temperature control, AISE Steel Tech., (2001) 55–59.

A. G. Groch, R. Gubernat and E. R. Birstein, Automatic control of laminar flow cooling in continuous and reversing hot strip mills, Iron and Steel Eng., 67(9) (1990) 16–20.

R. W. Moffat, M. C. Moore, M. J. Robinson and J. D. Ashton, Computer control of hot strip cooling temperature with variable flow laminar sprays, Iron and Steel Eng., 62(11) (1985) 21–28.

G. V. Ditzhuijzen, The controlled cooling of hot rolled strip: A combination of physical modeling, control problems and practical adaption, IEEE Trans. on Automatic Control, 38(7) (1993) 1060–1065.

M. D. Leltholf and J. R. Dahm, Model reference control of runout table cooling at LTV, Iron and Steel Eng., 66(8) (1989) 31–35.

N. S. Samaras and M. A. Simaan, Water-cooled end-point boundary temperature control of hot strip via dynamic programming, IEEE Transactions on Industry Applications, 34(6) (1998) 1335–1341.

N. S. Samaras and M. A. Simaan, Optimized trajectory tracking control of multistage dynamic metal-cooling processes, IEEE Transactions on Industry Applications, 37(3) (2001) 920–927.

S. K. Biswas, S. Chen and A. Satyanarayana, Optimal temperature tracking for accelerated cooling processes in hot rolling of steel, Dynamics and Control, 7 (1997) 327–340.

T. Harakawa and T. Kawaguchi, Digital control in iron and steel-making processes, Automatica, 20(5) (1993) 1185–1202.

R. K. Kumar, S. K. Sinha and A. K. Lahiri, An on-line parallel control for the runout table of hot strip mills, IEEE Transactions on Control Systems Technology, 9(6) (2001) 821–830.

S. Guan, H. X. Li and S. K. Tso, Multivariable fuzzy supervisory control for the laminar cooling process of hot rolled slab, IEEE Transactions on Control Systems Technology, 9(2) (2001) 348–356.

N. Hatta and H. Osakabe, Numerical modeling for cooling process of a moving hot plate by a laminar water curtain, The Iron and Steel Institute of Japan, 29(11) (1989) 919–925.

D. Auzinger and F. Parzer, Process optimization for laminar cooling, MPT International, 5 (1996) 68–75.

E. N. Hinrichsen and G. P. Petrus, Hot strip mill runout table cooling-A system view of control, operation and equipment, Iron and Steel Eng., 53(10) (1976) 29–34.

K. Yanagi, Prediction of strip temperature for hot strip mills, The Iron and Steel Institute of Japan, 16(1) (1976) 11–19.

H. Yoshida, A. Yorifuji, S. Koseki and M. Saeki, An integrated mathematical simulation of temperatures, rolling loads and metallurgical properties in hot strip mills, The Iron and Steel Institute of Japan, 31(6) (1991) 571–576.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Dae-Eun Kim

Cheol Jae Park received his B.S. and M.S. degrees in Mechanical Engineering from Pusan National University, Korea, in 1992 and 1994, respectively. He then received his Ph.D. degree from Seoul National University, Korea, in 2007. He is currently a Professor at the School of Automotive, Industrial and Mechanical Engineering at Daegu University, Korea. His research interests include receding horizon control, robust control, process control, system identification, and robotics.

Kang Sup Yoon received his B.S., M.S. and Ph.D. degrees in Mechanical Engineering from Pusan National University, Pusan, Korea, in 1986, 1988, and 1997, respectively. From September 1997 to February 2000, he was a postdoctoral fellow in the Institute of Industrial Science, University of Tokyo, Japan. He has been with the School of Automotive, Industrial and Mechanical Engineering, Daegu University, Gyeongsan, Korea, since April 2000. His current research interests include control theory, robotics, and mechatronics.

Chang Hoon Lee received his B.S., M.S. and Ph.D. degrees in Materials Science and Engineering from Seoul National University, Korea, in 1998, 2000 and 2005, respectively. Dr. Lee is currently a Senior Reseacher at the technical reseach laboratories of POSCO in Pohang, Korea. Dr. Lee’s research interests include high car-bon steels and high strength hot rolled steels.

Rights and permissions

About this article

Cite this article

Park, C.J., Yoon, K.S. & Lee, C.H. Advanced temperature control of high carbon steel for hot strip mills. J Mech Sci Technol 24, 1011–1017 (2010). https://doi.org/10.1007/s12206-010-0317-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-010-0317-4