Abstract

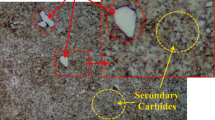

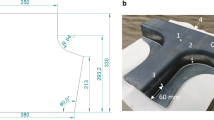

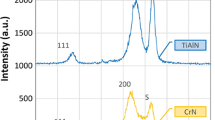

This experimental studies were carried out in order to understand the effects of the PVD coating and the UNSM treatment of HSS55 (high speed steel 55) during the production of the automotive inner pipe by the plastic deformation of S45C. The field test and the SEM images revealed that the PVD coating is necessary in spite of the high compressive residual stresses which were formed at the head of a punch pin. Upon the application of the AlCrN coating with the UNSM treatment the productivity and reliability of a punch pin had improved more than about 2.6 times compared to that of the TiN coating without the UNSM treatment. It is likely that the improvement is caused by the decreased stress concentration factor by the ‘wrapped in oxides’ inside of an abrasion pit. The abrasion pits were mostly generated within range of 5% ∼ 50% of the diameter ratio from the end of a pin and reached the maximum value about 17% from the end of a pin.

Similar content being viewed by others

References

C. M. Suh, M. H. Lee, B. W. Hwang and S. H. Kim, Damage Behavior in Ceramic Plasma-Coated and Uncoated Glass with Steel-Ball Impact, J. Am. Ceram. Soc., 86(7) (2003) 1220–1222.

C. M. Suh, B. W. Hwang and K. R. Kim, Effect of ceramic coating thickness on residual stress and fatigue characteristic of 1Cr-1Mo-0.25V steel, Int. J. of Modern Physics B, 16(1&2) (2002) 181–188.

F. Zhou, C. M. Suh, S. S. Kim and R. I. Murakami, Tribological behavior of CrN coating on aluminum alloys deposited by arc ion plating, J. of Materials Science (JMR), 17(12) (2002) 3133–3138.

C. M. Suh, F. Zhou, S. S. Kim and R. I. Murakami, Sliding wear behavior of TiN- and CrN-coated 2024 aluminum alloys against an Al2O3 ball, Tribology Letter, 13(3) (2002) 173–178.

C. M. Suh, B. W. Hwang and R. I. Murakami, Behaviors of residual stress and high-temperature fatigue life in ceramic coatings produced by PVD, Materials Science & Engineering, A343 (2003) 1–7.

C. M. Suh, S. H. Kim and D. Y. Suh, Experimental study of the impact damage on an Al2O3 coated glass under stress, Int. J. of Modern Physics B, 20(Nos.25–27) (2006) 4529–4534.

I. H. Cho, G. H. Song, C. M. Suh and Y. S. Pyoun et al., Nano Structured Surface Modification of Tool Steel and its Beneficial Effects in Mechanical Properties, J. of Mechanical Science and Technology, 19(11) (2005) 2151–2156.

Y. S. Pyoun and C. M. Suh, et. al., 2008, The ultrasonic nano-crystal surface modification technology and it’s application to improve fatigue strength, wear resistance, and service life & energy efficiency of bearings, Proceeding of ICSP-10, Tokyo, Japan, (2008) 416–421.

S. Mader and F. Klocke, Fundamentals of the Deep Rolling of Compressor Blades for Turbo Aircraft Engines, Proc. 9th Int. Conf. on Shot Peening, Technology Transfer Series, (2005) 125–130.

C. S. Montross, T. Wei, L. Ye, G. Clark and Y. W. Mai, Laser shock processing and its effects on microstructure and properties of metal alloys: a review, Int. J. of Fatigue, 24(10) (2002) 1021–1036.

I. Nikitin, I. Altenberger, H. J. Maier and B. Scholtes, Mechanical and thermal stability of mechanically induced near-surface nanostructures, Materials Science and Engineering, A403 (2005) 318–327.

R. K. Nalla, I. Altenberger, I. Noster, G. Y. Lui, B. Scholtes and R. O. Ritchie, On the influence of mechanical surface treatments — deep rolling and laser shock peening — on the fatigue behaviour of Ti-6Al-4V at ambient and elevated Temperatures, Materials Science and Engineering, A355 (2003) 216–230.

I. Altenberger, B. Scholtes, U. Martin and H. Oettel, Cycle deformation and near surface microstructures of shot peened or deep rolled Austenitic steel AISI 304, Materials Science and Engineering, A264 (1999) 1–16.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor In-Ha Sung

Chang-Min Suh received a B.S. and M.S. degree in Mechanical Engineering from Pusan National University. He received his Ph.D. degree from University of Tokyo, Japan in 1981. Dr. Suh is currently a Professor at the School of Mechanical Engineering at Kyungpook National University. From 1984 to 1985 he was a Visiting Professor in University of CA, Berkeley. He was the Head of Technology Innovation Center from 1995 until 2003, the Chairman of The 3rd International Conference on Advanced Materials Development and Performance in 2002, and the Editor and Co-Editor of International Journal of Modern Physics B of Vol. 17 and 20, World Scientific Publishing Co. Pte. Ltd., in April 2003 and October 2006, respectively. He has been a member of the National Academy of Engineering of Korea from 2003 until now. His research interests are Fatigue and Fracture Behavior of materials (Ceramic Coating).

Rights and permissions

About this article

Cite this article

Suh, CM., Oh, SY. & Pyun, YS. Enhancement of the punch pin durability induced by the PVD coating in production process of the automotive inner pipe. J Mech Sci Technol 24, 1061–1066 (2010). https://doi.org/10.1007/s12206-010-0314-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-010-0314-7