Abstract

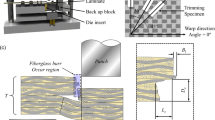

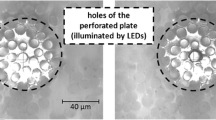

During the fiber preform loading process of resin transfer moldings (RTMs), fabric layers can be wrinkled in the preform, which affects the quality of the composite. This study considers several wrinkled models with different wrinkled lengths (L W ) and different numbers of wrinkled layers in the preform. To study the effects of wrinkling on tensile properties, two matrix materials with different moduli are used to enhance understanding. It is found that the tensile moduli of wrinkled models are lower than those of the normal model, for the same fiber volume fraction (V f ). The effects of wrinkling on the tensile modulus increase with the number of layers as well as V f . In addition, the effect of wrinkling with a low-modulus matrix on the tensile modulus is larger than that with a high-modulus matrix in the composite. Based on the failure modes and the stiffness of materials, the failure mechanisms of wrinkled models can be separated into two regimes as a function of wrinkled length, L W , depending on the critical wrinkled length (L WC ).

Similar content being viewed by others

References

B. Yang, V. Kozey, S. Adanur and S. Kumar, Bending, compression, and shear behavior of woven glass fiber-epoxy composites, Composites Part B 31 (2000) 715–721.

R. J. Day, P.A. Lovell and A. A. Wazzan, Toughened carbon/epoxy composites made by using core/shell particles, Composites Science and Technology 61 (2001) 41–56.

J. M. Lawrence, P. Fried and S. G. Advani, Automated manufacturing environment to address bulk permeability variations and race tracking in resin transfer molding by redirecting flow with auxiliary gates, Composites Part A 36 (2005) 1–14.

M. Deleglise, C. Binetruy and P. Krawczak, Solution to filling time prediction issues for constant pressure driven injection in RTM, Composites Part A 36 (2005) 339–344.

A. Cheung, Y. Yu and K. Pochiraju, Three-dimensional finite element simulation of curing of polymer composites, Finite Elements in Analysis and Design 40 (2004) 895–912.

J. Bystrom, N. Jekabsons and J. Varna, An evaluation of different models for prediction of elastic properties of woven composites, Composites Part B 31 (2000) 7–20.

G. Swaminathan, K. N. Shivakumar and M. Sharpe, Material property characterization of glass and carbon/vinyl ester composites, Composites Science and Technology 66 (2006) 1399–1408.

Y. Zhou, F. Pervin, V. K. Rangari and S. Jeelani, Fabrication and evaluation of carbon nano fiber filled carbon/epoxy composite, Materials Science & Engineering A 426 (2006) 221–228.

T. Hobbiebrunken, M. Hojo, T. Adachi, C. De Jong and B. Fiedler, Evaluation of interfacial strength in CF/epoxies using FEM and in-situ experiments, Composites Part A 27 (2006) 2248–2256.

J. A. Holmberg and L. A. Berglund, Manufacturing and performance of RTM U-beams, Composites Part A 28 (1997) 513–521.

K. Potter, B. Khan, M. Wisnom, T. Bell and J. Stevens, Variability, fiber waviness and misalignment in the determination of the properties of composite materials and structures, Composites Part A 39 (2008) 1343–1354.

H. Huang and R. Talreja, Effects of void geometry on elastic properties of unidirectional fiber reinforced composites, Composites Science and Technology 65 (2005) 1964–1981.

R. K. Pandey and C. T. Sun, Mechanisms of wrinkle formation during the processing of composite lamintes, Composites Science and Technology 59 (1999) 405–417.

Annual book of ASTM standards, 8 (1995).

P. K. Mallick, Fiber-reinforced composites, Marcel Dekker, New York, USA, (1998).

R. M. Jones, Mechanics of composite materials, McGraw-Hill Kogakusha, Tokyo, Japan, (1975).

P. T. Curtis, M. G. Blade and J. E. Bailey, The stiffness and strength of polyamide thermoplastic reinforced with glass and carbon fiber, J. of Mat. Sci. 13 (1978) 377–390.

H. Lanting and J. K. Spelt, Shear fracture of adhesively-bonded rigid elements, Composites Part B 28 (1997) 319–329.

L. K. Jain and Y. W. Mai, Analysis of resin-transfermoulded single-lap joints, Composites Science and Technology 59 (1999) 1513–1518.

L. Tong and G. P. Steven, A numerical study on stresses in resin transfer moulding lap joints reinforced with transverse stitching, Composite Structures 36 (1996) 91–100.

G. Kelly, Quasi-static strength and fatigue life of hybrid (bonded/bolted) composite single-lap joints, Composite Structures 72 (2006) 119–129.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Chongdu Cho

Thanh Trung Do received his B.S. in Mechanical Engineering from University of Technical Education HoChiMinh City in Vietnam on March 2000. He then received his M.S. degree on September 2003 and Ph.D. degree on August 2009 from Yeungnam University, Korea, where he is currently post-doctoral fellow. He is also member of University of Technical Education HoChiMinh City, Vietnam. His research interests focus on polymer matrix composites and experimental mechanics.

Dong Joo Lee received his B.E. in Mechanical Engineering from Yeungnam University, Korea, in 1979. He then received his M.S. and Ph.D. degrees from University of Massachusetts at Amherst in 1983 and 1987, respectively. Between 1987 and 1992, he was a research scientist at Honeywell Inc. in N.J. He is currently a Professor at the School of Mechanical Engineering at Yeungnam University. His research interests focus on polymer matrix composites, experimental mechanics and smart materials.

Rights and permissions

About this article

Cite this article

Do, T.T., Lee, D.J. Analysis of tensile properties for composites with wrinkled fabric. J Mech Sci Technol 24, 471–479 (2010). https://doi.org/10.1007/s12206-009-1207-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-009-1207-5