Abstract

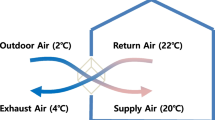

Three types of flow passage structure of a total heat exchanger (perforated type, slit type, and embossed and perforated type) are studied to enhance the heat exchange performance of a heat recovery ventilation system (total heat exchanger). The perforated type has four punched rows of 6mm holes in the flow passage channel, and the slit type has six processed rows of 40mm length. The embossed and perforated type has holes of about 1mm diameter and protrusions of about 0.2mm height on all surfaces. The heat exchange efficiency of the modified total heat exchanger was compared to that of a general total heat exchanger with a smooth surface. The Korean Standard (KS) heat recovery ventilator test condition was applied for tests. In the case of cooling operation based on a typical Reynolds number of 140 (typical air flow rate of 100 m3/hr), the perforated type, slit type, and embossed and perforated type showed temperature efficiency improvement of 1.2%, 2.5%, and 5.0%; latent efficiency improvement of 18.0%, 32.3%, and 24.5%; and enthalpy efficiency improvement of 7.9%, 11.5%, and 11.2%, respectively. The corresponding improvements of heating operation were 3.0%, 3.4%, and 4.0%; 5.0%, 6.6%, and 18.7%; 3.2%, 4.3%, and 7.7%, respectively. On the other hand, the air pressure drop throughout the modified flow passage of the total heat exchanger increased by up to 1.7% at the typical Reynolds number of 140, from the air pressure drop of the regular total heat exchanger.

Similar content being viewed by others

References

J. Dieckmann, K. W. Roth and J. Brodrick, Air-to-Air Energy Recovery Heat Exchangers, ASHRAE Journal, 45(8) (2003) 57–58.

M. Fehrm, W. Reiners and M. Ungemach, Exhaust Air Heat Recovery in Building, International Journal of Refrigeration, 25(4) (2002) 439–449.

E. Juodis, Extracted Ventilation Air Heat Recovery Efficiency as a Function of a Building’s Thermal Properties, Energy and Buildings, 38(6) (2006) 568–573.

R. M. Lazzarin and A. Gasparella, Technical and Economical Analysis of Heat Recovery in Building Ventilation System, Applied Thermal Engineering, 18(1–2) (1998) 47–67.

S. M. Kim, B. Y. Park and J. Y. Sohn, Evaluation of the Performance and the Energy Consumption Characteristics of Heat Recovery Ventilation in Apartments, Korean Journal of Air-conditioning and Refrigeration Engineering, 17(5) (2005) 496–504.

L. Z. Zhang and Y. Jiang, Heat and Mass Transfer in a Membrane-Based Energy Recovery Ventilator, Journal of Membrane Science, 163 (1999) 29–38.

L. Z. Zhang and J. L. Niu, Effectiveness Correlations for Heat and Moisture Transfer Processes in an Enthalpy Exchanger with Membrane Cores, ASME J. Heat transfer, 122(5) (2002) 922–929.

L. Z. Zhang, Heat and Mass Transfer in a Cross-Flow Membrane-Based Enthalpy Exchanger under Naturally Formed Boundary Conditions, International Journal of Heat and Mass Transfer, 50 (2007) 151–162.

C. H. Bai, Y. H. Lim, D. Gulnora, J. Y. Park, K. M. Kwak, E. S. Chu, Y. S. Kim and J. Y. Kim, A Study on the Characteristic of Total Heat Exchanger under Various Conditions, Korean Journal of Air-Conditioning and Refrigeration Engineering, 17(10) (2005) 891–897.

R. L. Webb, Principles of Enhanced Heat Transfer, Wiley, New York, (1994) 87–124.

KS B 6879, Heat Recovery Ventilators, (2003).

S. J. Kline and F.A. McClintock, Describing Uncertainties in Single Sample Experiments, Mechanical Engineering, 75 (1953) 3–8.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Dae Hee Lee

Kyungmin Kwak received his B.S., M.S. and Ph.D. degrees in Mechanical Engineering from Yeungnam University, Korea, in 1993, 1995 and 1999, respectively. Dr. Kwak is currently a Researcher at the Automotive RIC at Kyungil University, Korea. His research interests include heat transfer, refrigeration and air control.

Cheolho Bai received his B.S. and M.S. degrees in Mechanical Engineering from Seoul Na-tional University, Korea, in 1984 and 1986, respectively. He then received his Ph.D. from UCLA, USA, in 1992. Dr. Bai is currently a Professor at the School of Mechanical Engineering at Yeungnam University in Kyungsan, Korea. His research interests include heat transfer, refrigeration and air control.

Rights and permissions

About this article

Cite this article

Kwak, K., Bai, C. A study on performance improvement of corrugated type total heat exchanger considering the structure of flow passage on surface. J Mech Sci Technol 23, 1528–1535 (2009). https://doi.org/10.1007/s12206-009-0426-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-009-0426-0