Abstract

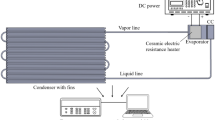

Loop heat pipes often experience start-up problems especially under low thermal loads. A bypass line was installed between the evaporator and the liquid reservoir to alleviate the difficulties associated with start-up of a loop heat pipe with flat evaporator. The evaporator and condenser had dimensions of 40 mm (W) by 50 mm (L). The wall and tube materials were stainless steel and the working fluid was methanol. Axial grooves were provided in the flat evaporator to serve as vapor passages. The inner diameters of liquid and vapor transport lines were 2 mm and 4 mm, respectively, and the length of the two lines was 0.5 m each. The thermal load range was up to 130 W for horizontal alignment with the condenser temperature of 10°C. The experimental results showed that the minimum thermal load for start-up was lowered by 37% when the bypass line was employed.

Similar content being viewed by others

References

Yu. F. Maidanik and Yu. G. Fershtater, Theoretical basis and classification of loop heat pipes and capillary pumped loops, Invited lecture, Proc. of The 10 th Int. Heat Pipe Conference, Stuttgart, Germany. (X-7D) (1997) 1–8.

Yu. F. Maidanik, Loop heat pipes, Applied Thermal Engineering, 25(5–6) (2005) 635–657.

I. Muraoka, F. M. Ramos and V. V. Vlassov, Analysis of the operational characteristics and limits of a loop heat pipe with porous element in the condenser, Int. J. of Heat and Mass Transfer, 44(12) (2001) 2287–2297.

B. Mo, M. M. Ohadi, S. V. Dessiatoun and K. R. Wrenn, Capillary pumped loop thermal performance improvement with electro-hydrodynamic technique, J. of Thermophysics and Heat Transfer, 14(1) (2000) 103–108

B. Mo, M. M. Ohadi, S. V. Dessiatoun and K. H. Cheung, Time reduction in as electrohydro-dynamically enhanced capillary pumped loop, J. of Thermophysics and Heat Transfer, 13(1) (1999) 134–139.

T. S. Zhao and Q. Liao, On capillary-driven flow and phase-change heat transfer in a porous structure heated by a finned surface: Measurements and Modeling, Int. J. of Heat and Mass Transfer, 43(7) (2000) 1141–1155.

D. Khrustalev and A, Faghri, A., Heat transfer in the inverted meniscus type evaporator at high heat fluxes, Int. J. of Heat Mass Transfer, 38(16) (1995) 3091–3101.

D. Khrustalev and A. Faghri, 1996, Estimation of the maximum heat flux in the inverted meniscus type evaporator of a flat miniature heat pipe, Int. J. of Heat and Mass Transfer, 39(9) (1996) 1899–1909.

H. Zhang, G. Lin, T. Ding, W. Yao, X. Shao, R. G. Sudakov and Yu. F. Maidanik, Investigation of startup behaviors of a loop heat pipe, J. of Thermophysics and Heat Transfer, 19(4) (2005) 509–518

J. H. Boo and W. B. Chung, Experimental study on the thermal performance of small-scale loop heat pipe with polypropylene wick, J. of Mechanical Science and Technology, 19(4) (2005) 1052–1061.

J. T. Dickey and G. P. Peterson, Experimental and analytical investigation of a capillary pumped loop, J. of Thermophysics and Heat Transfer 8(3) (1994) 602–607.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Dae Hee Lee

Joon Hong Boo received his B.S. degree in Mechanical Engineering from Seoul National University in 1978. He then received his M.S.M.E. and Ph.D. degrees from Georgia Institute of Technology in 1984 and 1989, respectively. Dr. Boo is currently a Professor in the School of Aerospace and Mechanical Engineering at Korea Aerospace University, where he joined in 1989. His research interests include heat transfer, heat pipes, and energy systems. He conducted joint research with Texas A&M University and Waseda University in 1994 and 2008, respectively, as Visiting Professor. Dr. Boo is an active member of the International Heat Pipe Conference Committee.

Eui Guk Jung received his B.S. and M.S. degrees in Aerospace and Mechanical Engineering from Korea Aerospace University, in 2002 and 2004, respectively. He is currently a Ph.D. candidate in the Graduate School at Korea Aerospace University. His research interests include applications of heat pipes and loop heat pipes.

Rights and permissions

About this article

Cite this article

Boo, J.H., Jung, E.G. Bypass line assisted start-up of a loop heat pipe with a flat evaporator. J Mech Sci Technol 23, 1613–1619 (2009). https://doi.org/10.1007/s12206-009-0405-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-009-0405-5