Abstract

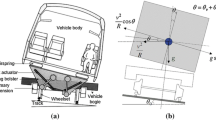

An advanced tilting system for KTT (Korean Tilting Train) was developed and a performance test of the system has been completed. KTT has been constructed to speed up and promise a significant enhancement in service quality on a conventional line. KTT is an electric multiple unit composed of 6 cars running at the design speed of 200 km/h. The tilting system is the core technology of KTT and combined with the conventional bogie system. It has a self-steering mechanism and a swing link. The self-steering mechanism of Z-bar type is free to rotate on the curve and stable to run on a straight line. The swing link mechanism of the bolster enables the carbody to tilt up to 8°. A tilting control system detects a curve with sensors and commands the electro-mechanical actuators to move the bolster through the computer network system. GPS collaborates with the tilting system to perceive the curve previously and enables gradual tilting so as not to violate passenger comfort. The performance of the tilting system has been verified by a trial test running of KTT on a commercial conventional line. The tilting system is ready for commercial use.

Similar content being viewed by others

References

KRRI, Development of practical technology for tilting system, Construction and Transportation R&D Report A01-I-5 (2007) 28–75.

Y. H. You, J. W. Um and K. Y. Eum, Allowable speed of tilting car in the conventional line, J. of the Korean Soc. for Railway, 6(4) (2003) 246–251.

S. I. Seo, S. H. Han, N. P. Kim and J. S. Kim, On the development of Korean Tilting Train eXpress, Proc. of the KSME 2006 Spring Annual Meeting, Korean Soc. of Mech. Engineers (2006) 28.

MOCT, Track, Regulations on Railway Construction, Ch. 2, Korea Government (2005) 4–17.

S. I. Seo, J. S. Kim and S. H. Cho, Development of hybrid composite bodyshell for tilting trains, J. of Rail and Rapid Transit (IMechE), 222,Part F (2008) 1–10.

K. Y. Eum, J. H. Um, Y. H. You and J. H. Choi, Evaluation of running stability of tilting trains in conventional curved track,, J. of the Korean Soc. for Railway, 7(4) (2004) 367–373.

S. H. Han, S. G. Lee and Y. S. Song, A Study on the Reduction Effects of Journey Time as Operating Korean Tilting Train, Proc. of the 37 th KIEE Summer Annual Conference 2006, Korean Institute of Elec. Engineers (2006) 1121–1123.

H. K. Gil, T. H. Ko, D. H. Cho and S. H. Han, Test research for performance verification of CV-NCM cast iron brake disk, Proc. of the Korean Soc. for Railway 2006 Autumn Annual Meeting, (2006) 85.

T. H. Ko, S. G. Lee, N. P. Kim and S. I. Seo, The design and the study for evaluation of performance for tilting pantograph, Proc. of the KSME 2006 Spring Annual Meeting, Korean Soc. of Mech. En gineers (2006) 292–297.

JIS, Truck frames for railway rolling stock — General rules for design, Japanese Industrial Standards, E 4207 (1989) 2–20.

UIC, 1994, Motive power units bogies and running gear bogie frame structure strength tests, International Union of Railway, Code 615-4 (1994) 3–50.

N. P. Kim, J. S. Kim, S. I. Seo, S. G. Lee and T. W. Park, A study on the dynamic characteristics evaluation of the tilting bogie, Proc. of the KSME 2006 Spring Annual Meeting, Korean Soc. of Mech. Engineers (2006) 259–264.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Hong Hee Yoo

SUNG IL SEO, Dr. Seo was born at Seoul, Korea in 1962. He graduated from Department of Naval Architecture, Seoul National University in 1984 and received a doctor degree from the same university in 1994. He entered Hanjin Heavy Industries Co. in 1986 and was engaged in structural design of ship and development of aluminum rolling stocks. He transferred to KRRI in 2002. He was engaged in development of Korea High Speed Train. He has been in charge of the development project for Korea Tilting Train. He published many research papers on high speed train, structural design and welding deformations in international journals.

Rights and permissions

About this article

Cite this article

Seo, S.I., Kim, N.P., Lee, S.G. et al. Development of a tilting system for electric multiple unit to speed up on conventional lines. J Mech Sci Technol 22, 2171–2179 (2008). https://doi.org/10.1007/s12206-008-0722-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-008-0722-0