Abstract

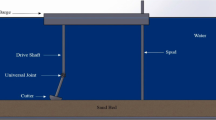

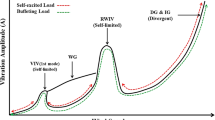

Vibration has severely increased at the branch pipe of the main steam header since the beginning of commercial operation of nuclear power plants. Intense broadband disturbance flow at a discontinuous region such as elbows, valves or headers generates an acoustical pulsation which is propagated through the piping system. The pulsation becomes the source of low frequency vibration at the piping system. If it coincides with the natural frequency of the pipe system, excessive vibration results. High-level vibration due to the pressure pulsation related to high dynamic stress, and ultimately, to failure probability fatally affects the reliability and confidence of the plant piping system. This paper discusses steady-state high vibrations appearing in the branch piping system due to the effect of acoustical pulsations transmitted from the large main steam header by broadband turbulence in a 700 MW power plant. The excitation sources and response of the piping system are investigated by using on-site measurements and analytical approaches. Energy absorbing restraints with additional stiffness and damping factor were designed and installed to reduce vibration damage.

Similar content being viewed by others

References

R. T. Hartlen and W. Jaster, Main steam piping vibration driven by flow-acoustic excitation, IAHR/IUTAM Symposium (A7), Karlsruhe, (1979) 144–152.

Walter W. von Nimitz Low frequency vibrations at centrifugal plants, Proceedings of the Fourth Turbomachinery Symposium, 47–54.

S. Ziada, Flow-excited resonances of piping systems containing side-branches: Excitation mechanism, counter-measures and design guidelines, Seminar on Acoustic Pulsations in Rotating Machinery, Toronto Ontario, Canada, (1993).

R. J. Gibert and F. Axisa, B. Villard, Flow induced vibrations of piping system, KESWICK-U.K May. (1978) 617–623.

ASME, Standard and Guides for Operations and Maintenance of Nuclear Power Plants, part 3 APPENDIX D. (1990).

Y. W. Kim, Dynamic characteristics study on vibration of main steam piping for a power plant, Asia-Pacific Vibration Conference. (1997) 687–692.

J. H. Jeon and Y. H. Kim, Prediction of sound field inside duct with moving medium by using one dimensional Green’s function, Proceedings of the KSNVE Annual Autumn Conference. (2005) 915–918.

K. W. Ryu and J. S. Lee, A study on the chattering noise elimination of the check valve, Proceedings of the KSNVE June Annual Conference. (2000) 1848–1853.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, YW., Lee, YS. Damage prevention design of the branch pipe under pressure pulsation transmitted from main steam header. J Mech Sci Technol 22, 647–652 (2008). https://doi.org/10.1007/s12206-007-1205-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-007-1205-4