Abstract

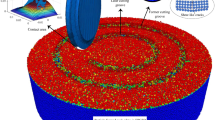

Roadheaders have been increasingly used in a variety of tunnel cross-sections and roadway excavations. The appropriate setting of key construction parameters of the roadheader can maintain the excellent cutting performance of the roadheader during excavation. In this respect, this paper reviews in detail the previous studies on various experiments and numerical simulations affecting the cutting performance parameters of roadheader. A method for simulating the breaking process during the mechanical cutting of rock was then introduced using the Particle Flow Code in 3 Dimensions (PFC3D). In the numerical simulations, we used the parallel bond model to simulate the studied rock material and completed the calibration of the mesoscopic parameters by numerical simulation tests. In the simulations, we set different cutting modes, cutting depths and cutting thicknesses to study the rock breaking process of the transverse cutter head in a highly weathered granite environment from a microscopic perspective. The simulations indicated that the cutting mode, cutting depth and cutting thickness have significant effects on the cutting force and specific energy consumption. It is feasible to use the available space to the fullest and effectively reduce the wear of the picks by adopting the undercutting mode. The cutting efficiency can be improved and the specific energy consumption of cutting can be significantly decreased by increasing the cutting depth. The optimal cutting depth for highly weathered granite is 13 cm. As the cutting thickness increases, the cutting head’s normal and rolling forces increase linearly, and the cutting efficiency improves. Under the condition of highly weathered granite, the maximum cutting thickness of the Erkat ER1500 transverse cutting head is 12.5 cm. Overall, the results indicate that the discrete element method is a powerful tool for simulating rock cutting process.

Similar content being viewed by others

References

Acaroglu O, Erdogan C (2017) Stability analysis of roadheaders with mini-disc. Tunnelling and Underground Space Technology 68:187–195, DOI: https://doi.org/10.1016/j.tust.2017.05.027

Acaroglu O, Ergin H (2005) The effect of cutting head shapes on roadheader stability. Mining Technology 114(3):140–146, DOI: https://doi.org/10.1179/037178405X54015

Bilgin N, Dincer T, Copur H, Erdogan M (2004) Some geological and geotechnical factors affecting the performance of a roadheader in an inclined tunnel. Tunnelling and Underground Space Technology 19(6):629–636, DOI: https://doi.org/10.1016/j.tust.2004.04.004

Comakli R (2019a) Effects of the physico-mechanical properties of low-strength pyroclastic rocks on cutter wear of roadheaders. Wear 428:205–216, DOI: https://doi.org/10.1016/j.wear.2019.03.014

Comakli R (2019b) Performance of roadheaders in low strength pyroclastic rocks, a case study of cold storage caverns in Cappadocia. Tunnelling and Underground Space Technology 89:179–188, DOI: https://doi.org/10.1016/j.tust.2019.04.007

Dai Y, Wang M (2009) Construction technology for extra-shallow covered mined tunnel on No.3 Line of Chongqing MRT System. Tunnel Construction 29(S2):167–170 (in Chinese)

Deshmukh S, Raina AK, Murthy VMSR, Trivedi R, Vajre R (2020) Roadheader — A comprehensive review. Tunnelling and Underground Space Technology 95:103148, DOI: https://doi.org/10.1016/j.tust.2019.103148

Elyasi S (2021) Developing an evaluation model for economic feasibility analysis of using mechanical boring machines (TBM vs Roadheader) in one of the largest coal reserves in Iran. Mining, Metallurgy & Exploration 38(2):1081–1094, DOI: https://doi.org/10.1007/s42461-021-00391-1

Eyyuboglu EM, Bolukbasi N (2005) Effects of circumferential pick spacing on boom type roadheader cutting head performance. Tunnelling and Underground Space Technology 20(5):418–425, DOI: https://doi.org/10.1016/j.tust.2005.02.002

Goktan RM, Gunes Yilmaz N (2005) A new methodology for the analysis of the relationship between rock brittleness index and drag pick cutting efficiency. Journal of the Southern African Institute of Mining and Metallurgy 105(10):727–733, https://hdl.handle.net/10520/AJA0038223X3063

Hekimoglu OZ (1991) Comparison of longitudinal and transverse cutting heads on a dynamic and kinematic basis. Mining Science and Technology 13(3):243–255, DOI: https://doi.org/10.1016/0167-9031(91)90368-M

Hekimoglu OZ (2018) Investigations into tilt angles and order of cutting sequences for cutting head design of roadheaders. Tunnelling and Underground Space Technology 76:160–171, DOI: https://doi.org/10.1016/j.tust.2018.03.017

Huang H, Lecampion B, Detournay E (2013) Discrete element modeling of tool-rock interaction I: Rock cutting. International Journal for Numerical and Analytical Methods in Geomechanics 37(13):1913–1929, DOI: https://doi.org/10.1002/nag.2113

Jang JS, Yoo WS, Kang H, Cho JW, Jeong MS, Lee SK, Cho YJ, Lee JW, Rostami J (2016) Cutting head attachment design for improving the performance by using multibody dynamic analysis. International Journal of Precision Engineering and Manufacturing 17(3):371–377, DOI: https://doi.org/10.1007/s12541-016-0046-4

Jeong H, Choi S, Lee S, Jeon S (2020) Rock cutting simulation of point attack picks using the smooth particle hydrodynamics technique and the cumulative damage model. Applied Sciences 10(15):5314, DOI: https://doi.org/10.3390/app10155314

Jiang HX, Liu SY, Du CL, Gao KD (2013) Numerical simulation of rock fragmentation process by roadheader pick. Journal of Vibroengineering 15(4):1807–1817

Kotwica K (2011) The influence of water assistance on the character and degree of wear of cutting tools applied in roadheaders. Archives of Mining Sciences 56(3):353–374

Kotwica K (2018) Atypical and innovative tool, holder and mining head designed for roadheaders used to tunnel and gallery drilling in hard rock. Tunnelling and Underground Space Technology 82:493–503, DOI: https://doi.org/10.1016/j.tust.2018.08.017

Kou S, Lindqvist PA, Tang CA, Xu XH (1999) Numerical simulation of the cutting of inhomogeneous rocks. International Journal of Rock Mechanics and Mining Sciences 36(5):711–717, DOI: https://doi.org/10.1016/S0148-9062(99)00039-X

Li XY, Huang BB, Ma GY, Zeng QL (2013) Study on roadheader cutting load at different properties of coal and rock. The Scientific World Journal 2013, DOI: https://doi.org/10.1155/2013/624512

Liu ZH, Du CL, Jiang HX, Liu K (2017a) Analysis of roadheader for breaking rock containing holes under confining pressures. Energies 10(8):1154, DOI: https://doi.org/10.3390/en10081154

Liu XN, Du CQ, Liu MX (2020) Research on spiral angle optimization for longitudinal road header’s cutting head. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 234(17):3346–3359, DOI: https://doi.org/10.1177/0954406220915491

Liu ZH, Du CL, Zheng YL, Zhang QB, Zhao J (2017b) Effects of nozzle position and waterjet pressure on rock-breaking performance of roadheader. Tunnelling and Underground Space Technology 69:18–27, DOI: https://doi.org/10.1016/j.tust.2017.06.003

Liu SY, Ji HF, Han DD, Guo CW (2018) Experimental investigation and application on the cutting performance of cutting head for rock cutting assisted with multi-water jets. The International Journal of Advanced Manufacturing Technology 94(5):2715–2728, DOI: https://doi.org/10.1007/s00170-017-1072-9

Liu SY, Ji HF, Liu XH (2017c) Effect of pick working angle on the cutting performance of a cutting head. Journal of the Brazilian Society of Mechanical Sciences and Engineering 39(10):4147–4159, DOI: https://doi.org/10.1007/s40430-017-0806-9

Lunardi P (2008) Design and construction of tunnels: Analysis of Controlled Deformations in Rock and Soils (ADECO-RS). Springer Science & Business Media

Menezes PL (2017) Influence of cutter velocity, friction coefficient and rake angle on the formation of discontinuous rock fragments during rock cutting process. The International Journal of Advanced Manufacturing Technology 90(9):3811–3827, DOI: https://doi.org/10.1007/s00170-016-9694-x

Neil DM, Rostami J, Ozdemir L, Gertsch R (1994) Production estimating techniques for underground mining using roadheaders. Preprints-Society of Mining Engineers of Aime

Nishimatsu Y (1972) The mechanics of rock cutting. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts 9(2):261–270, DOI: https://doi.org/10.1016/0148-9062(72)90027-7

Ocak I, Bilgin N (2010) Comparative studies on the performance of a roadheader, impact hammer and drilling and blasting method in the excavation of metro station tunnels in Istanbul. Tunnelling and Underground Space Technology 25(2):181–187, DOI: https://doi.org/10.1016/j.tust.2009.11.002

Park JY, Kang H, Lee JW, Kim JH, Oh JY, Cho JW, Rostami J, Kim HD (2018) A study on rock cutting efficiency and structural stability of a point attack pick cutter by lab-scale linear cutting machine testing and finite element analysis. International Journal of Rock Mechanics and Mining Sciences 103:215–229, DOI: https://doi.org/10.1016/j.ijrmms.2018.01.034

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. International Journal of Rock Mechanics and Mining Sciences 41(8):1329–1364, DOI: https://doi.org/10.1016/j.ijrmms.2004.09.011

Rojek J, Oñate E, Labra C, Kargl H (2011) Discrete element simulation of rock cutting. International Journal of Rock Mechanics and Mining Sciences 48(6):996–1010, DOI: https://doi.org/10.1016/j.ijrmms.2011.06.003

Su O, Akcin NA (2011) Numerical simulation of rock cutting using the discrete element method. International Journal of Rock Mechanics and Mining Sciences 48(3):434–442, DOI: https://doi.org/10.1016/j.ijrmms.2010.08.012

Su O, Akkaş M (2020) Assessment of pick wear based on the field performance of two transverse type roadheaders: A case study from Amasra coalfield. Bulletin of Engineering Geology and the Environment 79(5): 2499–2512, DOI: https://doi.org/10.1007/s10064-019-01712-x

Sun W, Wang C, Chen J (2011) Milling excavation technique of Liangshui Tunnel embedded in soft rocks. Modern Tunnelling Technology 48(2):170–173, DOI: https://doi.org/10.13807/j.cnki.mtt.2011.02.035 (in Chinese)

Xu YD (2021) Effect of cutting angle on the performance of the head of a roadheader. Journal of Mechatronics and Artificial Intelligence in Engineering 2(1):54–62, DOI: https://doi.org/10.21595/jmai.2021.22042

Zhang B (2018) Study on the technology and excavation adaptability of the cantilever tunneling machine for milling tunneling. MSc Thesis, Dalian Jiaotong University, Dalian, China (in Chinese)

Zhang DY, Liu SY, Jia XQ, Cui YM, Yao J (2022) Full coverage cutting path planning of robotized roadheader to improve cutting stability of the coal lane cross-section containing gangue. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 236(1):579–592, DOI: https://doi.org/10.1177/095440622199639

Zhang X, Liu XZ, Zhang JW, Zeng QL (2011) Multi-objective optimization design for cutting head of roadheader. Key Engineering Materials 450:75–78, DOI: https://doi.org/10.4028/u]www.scientific.net/KEM.450.75

Zhang M, Yan X, Qin G (2021) A new method for roadheader pick arrangement based on meshing pick spatial position and rock cutting verification. PLoS ONE 16(11):e0260183, DOI: https://doi.org/10.1371/journal.pone.0260183

Zong K, Fu SC, Wu M (2021) Modeling and response analysis of the attitude angles of roadheader for steep coal seam. SN Applied Sciences 3(8):1–16, DOI: https://doi.org/10.1007/s42452-021-04717-y

Acknowledgments

This research was supported by the National Natural Science Foundation of China (U1934213), the Science and Technology Program of Nanchang Rail Transit Group Limited Corporation of China (2019HGKYB003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, K., Liu, Z. & Zhang, Z. A Case Study of Cutting Performance by a Transverse Cutting Head Based on Three-Dimensional Particle Flow Model. KSCE J Civ Eng 27, 2248–2262 (2023). https://doi.org/10.1007/s12205-023-1683-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-023-1683-7