Abstract

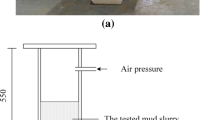

When earth pressure balance (EPB) shield machine is driving in mudstone sand pebble composite stratum, it will produce a large amount of spoil with high water content. The high moisture content of spoil not only increases the difficulty and cost of transportation, but also easily leads to environmental pollution problems. In this paper, based on the shield tunnel project of Chengdu Metro Line 30, the hydraulic characteristic of shield spoil was tested, and on this basis, laboratory tests of shield spoil dehydration were carried out according to the designed precipitation scheme. The results show that: 1) The moisture content of the EPB shield spoil in the mudstone sand pebble composite stratum is as high as 55.2%, and its permeability coefficient is basically the same as that of silt, and the shield residue has the condition of in-situ dehydration. 2) The dehydration amount and residue moisture content of spoil in slope-type spoil pit showed a linear relationship with time, and the dehydration rate is slow and the total precipitation is less. In other schemes, the dehydration amount and water content of spoil increase rapidly in the first 24 hours and slowly in the later period. 3) Considering the total amount and speed of dehydration within 24 hours, the dehydration effect of spoil pit is ranked from high to low: 3D gravel cage wall spoil pit > 3D spoil pit with vacuum pumping > 3D permeable stone spoil pit > 3D spoil pit > Slope-type spoil pit. 4) 3D gravel cage wall spoil pit has high dewatering efficiency, and vacuum pumping can assist the discharge of water. It is recommended to use 3D gravel cage wall spoil pit and vacuum pumping scheme for on-site EPB tunnel spoil dewatering.

Similar content being viewed by others

References

Al-Mukhtar M, Khattab S, Alcover JF (2012) Microstructure and geotechnical properties of lime-treated expansive clayey soil. Engineering Geology 139–140:17–27, DOI: https://doi.org/10.1016/j.enggeo.2012.04.004

Chen ZM (2023) Analysis of the function of environmental detection and environmental protection measures. Leather Manufacture and Environmental Technology 4(2):101–102,105, DOI: https://doi.org/10.20025/j.cnki.CN10-1679.2023-02-35

China URTA (2023) 2022 annual statistics and analysis report on urban rail transit. Urban Rail Transit, Retrieved March 31, 2023, https://www.camet.org.cn/tjxx/11944

Ding ZY, Liu T, Zhang Y, Su XT, Zheng JG (2022) The curing and strength properties of highly moist waste mud from slurry shield tunnel construction. Applied Sciences 12(8):3762, DOI: https://doi.org/10.3390/APP12083762

Dizon A, Orazem ME (2020) Advances and challenges of electrokinetic dewatering of clays and soils. Current Opinion in Electrochemistry (prepublish) 22:17–24, DOI: https://doi.org/10.1016/j.coelec.2020.03.002

Dong ZF, Li HX, Wu Q, Yu EY, Qiu L (2012) The ‘Twelfth Five-Year’ five new highlights of environmental policy. Environmental Protection and Circular Economy 2012(9):4–13, DOI: https://doi.org/10.3969/j.issn.1674-1021.2012.09.002

Fei YH, Zhou CQ (2015) Application of centrifuge system in construction mud reduction process. Construction Science and Technology (5): 106–107, DOI: https://doi.org/10.16116/j.cnki.jskj.2015.05.022

Feng AJ (2022) Data statistics and development analysis of China’s urban rail transit in 2021. Tunnel Construction (Chinese and English) 42(2):336–341

Gan H, Li WS, Xiao GH (2023) Discussion on the design details of mud dewatering screens for shield tunnel engineering. China Plant Engineering 2023(11):127–129

Geng PF, Sun LZ (2014) Experimental study on composite flocculant for mud pressure filtration dehydration. Journal of Wuhan University of Technology 36(5):118–122+144

Guo X (2016) Process design and engineering practice of centrifugal dewatering treatment of construction waste mud. Building Construction 38(3):335–337, DOI: https://doi.org/10.14144/j.cnki.jzsg.2016.03.032

Hua JX, Zheng JG (2018) Geological engineering handbook. China Architecture & Amp; Building Press

Iwata M, Tanaka T, Jami MS (2013) Application of electroosmosis for sludge dewatering — A review. Drying Technology 31(2):170–184, DOI: https://doi.org/10.1080/07373937.2012.691592

Jiang LB, Zhen L, Wang JF, Zhang T, Huang XW (2022) Research on dewatering characteristics of waste slurry from pipe jacking construction. Materials 15(6):2242, DOI: https://doi.org/10.3390/MA15062242

Li H, Fu LL (2020) Overview of research on urban environmental protection mechanisms in China. Chemical Enterprise Management 2020(6):58–59, DOI: https://doi.org/10.3969/j.issn.1008-4800.2020.06.039

Li Y, Miao BQ, Zou YL, Li M, Chen S, Qi HY (2022) Application analysis of small shield tunnel slurry treatment system. China Plant Engineering 2022(18):102–104

Liang ZS, Yang CQ, Gao HY, Wu ZR (2016) Experimental study on rapid mud water separation of construction waste mud. Journal of Southeast University (Natural Science Edition) 46(2):427–433

Liu CW, Lu SL (2000) Study on disintegration softening mechanism of mudstone in water. Geotechnical Mechanics (1):28–31, DOI: https://doi.org/10.16285/j.rsm.2000.01.008

Liu FY, Zhu CG, Yang KJ, Ni JF, Hai J, Gao SH (2019) Effects of fly ash and spoil content on the solidification of river-dredged sludge. Marine Georesources & Geotechnology 39(1):65–73, DOI: https://doi.org/10.1080/1064119x.2019.1677827

Long QY (2019) Practical technology for waste mud treatment in railway bridge construction. Chinese Place Names (7):36

Mao CX (2009) Manual of embankment engineering. China Water Resources and Hydropower Press

Ministry of Water Resources of the People’s Republic of China (2019) GB/T 50123-2019. Ministry of housing and urban rural development of the people’s Republic of China; State Administration of market supervision and administration

Quan ZX, Chen XS, Chen F, Gao W, Han WL (2023) Analysis carbon reduction effect of tunnel construction muck soil utilization based on life cycle assessment. Environmental Engineering 1–9[2023-07-04], http://kns.cnki.net/kcms/detail/11.2097.X.20230616.1054.010.html

Santos AF, Vaz TE, Lopes DV, Cardoso O, Quina M (2021) Beneficial use of lime mud from kraft pulp industry for drying and microbiological decontamination of sewage sludge. Journal of Environmental Management 296:113255

Shen XL (2018) Research and application of a new composite flocculant in construction mud treatment. Construction 40(4):563–565, DOI: https://doi.org/10.14144/j.cnki.jzsg.2018.04.040

Sun WG, Zhang GJ, Ren X, Chen J (2015) Research and application of construction spoil (mud) improvement technology. Underground Engineering and Tunnel (4):34–37+58, DOI: https://doi.org/10.13547/j.cnki.dxgcysd.2015.04.009

Wang SY, Liu PF, Hu QX, Wang HB, Huang S, Zhong JZ, Liu ZR, Yang JS (2020) Summary of research on the theory and technology of shield tunnel muck improvement. Journal of China Highway 33(5):8–34, DOI: https://doi.org/10.19721/j.cnki.1001-7372.2020.05.002

Wang GH, Liu BL, Xia BR (2005) Study on Solidification Technology of waste mud from geotechnical engineering construction. Prospecting Engineering (Geotechnical Drilling and Excavation Engineering) (9):10–11, 14

Wang DX, Wu LF, Tang YK, Xu XY (2020) Separation process and effect evaluation of construction waste mud. Journal of Zhejiang University (Engineering Edition) 54(6):1049–1057

Wang Z, Wu XP, Lu QS, Peng GB, Jiang H, Zhang H, Liu Y, Feng XD (2018) Research on field treatment technology of Engineering mud. Western Prospecting Project 30(4):25–26+28

Wen L, Yan CH, Yang XY, Li LW (2022) Effect of fly ash addition on slurry dewatering by electro-osmosis combined with mechanical pressure. Drying Technology 40(5)

Xie XY, Liu YM, Zheng LW (2019) Experimental study on the effect of soil saturation on the electric permeability coefficient during electroosmosis process. Marine Georesources & Geotechnology 37(10):1188–95, DOI: https://doi.org/10.1080/1064119X.2018.1540673

Xu SL, Shi JQ, Deng J, Sun HL, Wu JW, Ye ZH (2023) Flocculation and dewatering of the Kaolin slurry treated by single- and dualpolymer flocculants. Chemosphere, 328

Yang HX, Du J, Gong ZY, Xiao G, Ni ZL, Wang SY (2023) Study on solidification mechanism and application of high water content foam-conditioned muck of central Yunnan water diversion project shield Tunnel. Forest Engineering 39(3):172–181

Yang CY, Xu W, Bai CG (2013) Construction waste mud flocculation dehydration test and mechanism analysis. Environmental Science and Technology 26(5):15–17+21

Zhang XD, Lu YT, Yao J, Wu YJ, Tran QC, Vu QV (2020) Insight into conditioning landfill sludge with ferric chloride and a Fenton reagent: Effects on the consolidation properties and advanced dewatering. Chemosphere (prepublish) 252:126528, DOI: https://doi.org/10.1016/j.chemosphere.2020.126528

Zhang H, Ma QG, Su WJ, Hu H (2021) On the dewatering of electroosmotic soil using intermittent current incorporated with calcium chloride. Environmental Technology 42(3):468–478, DOI: https://doi.org/10.1080/09593330.2019.1634154

Zhang ZQ, Xia SQ, Zhang J (2010) Enhanced dewatering of waste sludge with microbial flocculant TJ-F1 as a novel conditioner. Water Research 44(10):3087–3092, DOI: https://doi.org/10.1016/j.watres.2010.02.033

Zhou XB, Sun XH, Li YJ, Liu HP, Liang S (2021) Research on high-efficiency dewatering and reduction treatment of shield waste residue based on DME phase transition. Modern Urban Transit 2021(S1):46–50

Acknowledgments

This study was supported by the Scientific and Technological Innovation Project of General Projects of Sichuan Provincial Department of Science and Technology (grant number 2022NSFSC0318). It was also supported by the Scientific and Technological Innovation Project of China First Highway Engineering Group (grant numbers X-GD-8GS(J)-SIC-CDDT-02-JS-003 and X-GD-8GS(J)-SIC-CDDT-02-JS-004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, D., Wen, S., He, Q. et al. In-Situ Dehydration Test of Shield Spoil in Mudstone and Pebble Soil Composite Stratum. KSCE J Civ Eng 28, 93–105 (2024). https://doi.org/10.1007/s12205-023-1612-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-023-1612-9