Abstract

This paper presents an experimental investigation into the impact performance of Ferro-cement panels incorporating a significant proportion of geopolymer mortar. This panel could be an effective replacement for prefabricated roof and floor deck construction elements. In this study, the geopolymer mortar includes wastes disposed from industries like ground granulated blast furnace slag (GGBFS) and flyash as their base material which contributes to reduced CO2 emission. The pore filling and element densifying mechanism is enhanced by the addition of Nano flyash. The fine aggregate is replaced up to 5% with treated tyre crumb rubber which can be utilized as a sustainable construction material. The cast panel was cured at 80oC for 48 hours in the oven. The incorporation of Expanded Metal Mesh into geopolymer mortar results in higher impact load absorption capacity rather than other kind of reinforcing meshes. The GGBFS based Geopolymer results in 17% higher compressive strength than fly ash based geopolymer because of its good bonding nature. The Nano fly ash based geopolymer gives 35 MPa in compressive strength and 902.52 joules in impact energy absorption which is greatest among all panels because of its densifying effect of mortar.

Similar content being viewed by others

References

ACI 544.2R-89 (1989) Measurement of properties of fiber reinforced concrete. ACI 544.2R-89, American Concrete Institute, Farmington Hills, MI, USA

ACI 549R-97 (2009) State-of-the-art report on ferrocement ACI 549R-97, American Concrete Institute, Farmington Hills, MI, USA

ASTM C642 (2013) Standard test method for density, absorption, and voids in hardened concrete. ASTM C642, American Society for Testing and Materials, West Conshohocken, PA, USA

ASTM D2794-93 (2010) Standard test method for resistance of organic coatings to the effects of rapid deformation (impact). ASTM D2794-93, American Society for Testing and Materials, West Conshohocken, PA, USA

Behnia A, Ranjbar N, Chai HK, Abdulla AI, Masaeli M (2017) Fracture characterization of multi-layer wire mesh rubberized ferrocement composite panels by means of acoustic emission. Journal of Cleaner Production 157:134–147, DOI: 10.1016/j.jclepro.2017.03.192

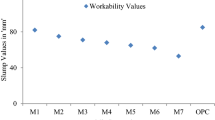

Deb PS, Nath P, Sarker PK (2014) The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Materials and Design 62:32–39, DOI: 10.1016/j.matdes.2014.05.001

Elyamany HE, Elmoaty AEM Abd, Elshaboury AM (2018) Setting time and 7-day strength of geopolymer mortar with various binders. Construction and Building Materials 187:974–983, DOI: 10.1016/j.conbuildmat.2018.08.025

IS 383 (1987) Specification for coarse and fine aggregate. IS 383, Indian Standards, New Delhi, India

IS 1237 (2012) Cement concrete flooring tiles specification. IS 1237, Indian Standards, NewDelhi, India

IS 4031 (1988) Methods of physical tests for hydraulic cement (part 6). IS 4031, Indian standards, New Delhi, India

Hago AW, Jabri KS Al, Alnuaimi AS, Moqbali H Al, Kubaisy MA Al (2005) Ultimate and service behavior of ferrocement roof slab panels. Construction and Building Materials 19:31–37, DOI: 10.1016/j.conbuildmat.2004.04.034

Kwasny J, Soutsos MN, McIntosh JA, Cleland DJ (2018) Comparison of the effect of mix proportion parameters on behaviour of geopolymer and Portland cement mortars. Construction and Building Material 187:635–651, DOI: 10.1016/j.conbuildmat.2018.07.165

Luga E, Atis CD (2018) Optimization of heat cured fly ash and slag blend geopolymer mortars designed by “Combined Design” method: Part 1. Construction and Building Materials 178:393–404, DOI: 10.1016/j.conbuildmat.2018.05.140

Mucsi G, Szenczi A, Nagy S (2018) Fiber reinforced geopolymer from synergetic utilization of fly ash and waste rubber tire. Journal of Cleaner Production 178:429–440, DOI: 10.1016/j.jclepro.2018.01.018

Nagan S, Mohana R (2014) Behaviour of geopolymer ferrocement panels subjected to impact. Iranian Journal of Science and Technology - Transactions of Civil Engineering 38(C1):223–233

Park Y, Abolmaali A, Kim YH, Ghahremannejad M (2016) Compressive KSCE Journal of Civil Engineering 11 strength of fly ash-based geopolymer concrete with crumb rubber partially replacing sand. Construction and Building Materials 118:43–51, DOI: 10.1016/j.conbuildmat.2016.05.001

Patel YJ, Shah N (2018) Enhancement of the properties of ground granulated blast furnace slag based self compacting geopolymer concrete by incorporating rice husk ash. Construction and Building Materials 171:654–662, DOI: 10.1016/j.conbuildmat.2018.03.166

Saha S, Rajasekaran C (2017) Enhancement of the properties of fly ash based geopolymer mortar by incorporating ground granulated blast furnace slag. Construction and Building Materials 146:615–620, DOI: 10.1016/j.conbuildmat.2017.04.139

Samantasinghar S, Singh SP (2018) Effect of synthesis parameters on compressive strength of fly ash-slag blended geopolymers. Construction and Building Materials 170:225–234, DOI: 10.1016/j.conbuildmat.2018.03.026

Shaaban IG, Shaheen YB, Elsayed EL, Kamal OA, Adesina PA (2018) Flexural characteristics of lightweight ferrocement beams with various types of core materials and mesh reinforcements. Construction and Building Materials 171:802–816, DOI: 10.1016/j.conbuildmat. 2018.03.167

Shang J, Dai JG, Zhao TJ, Guo S Y, Zhang P, Mu B (2018) Alternation of traditional cement mortars using fly ash-based geopolymer mortars modified by slag. Journal of Cleaner Production 203:746–756, DOI: 10.1016/j.jclepro.2018.08.255

Temuujin J, Riessen AV, MacKenzie KJD (2010) Preparation and characterisation of fly ash based geopolymer mortars. Construction and Building Materials 24:1906–1910, DOI: 10.1016/j.conbuildmat. 2010.04.012

Tudjono S, Purwanto Apsari KT (2014) Study the effect of adding nano fly ash and nano lime to compressive strength of mortars. Procedia Engineering 95:426–432, DOI: 10.1016/j.proeng.2014.12.202

VenuMadhav T, Reddy IVR, Ghorpade VG, Jyothirmai S (2018) Compressive strength study of geopolymer mortars using quarry rock dust. Materials Letters 231:105–108, DOI: 10.1016/j.matlet. 2018.07.133

Wardhono A, Gunasekara C, Law DW, Setunge S (2017) Comparison of long-term performance between alkali activated slag and fly ash geopolymer concrete. Construction and Building Materials 143:272–279, DOI: 10.1016/j.conbuildmat.2017.03.153

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajendran, M., Akasi, M. Performance of Crumb Rubber and Nano Fly Ash Based Ferro-Geopolymer Panels under Impact Load. KSCE J Civ Eng 24, 1810–1820 (2020). https://doi.org/10.1007/s12205-020-0854-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-020-0854-z