Abstract

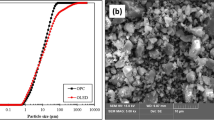

In this study, the fundamental and mineralogical properties of the binary system incorporating the industrial display byproducts, liquid crystal display (LCD) and organic light emitting diodes (OLED), as a cementitious material. A substitution level of the fine glass powders, and water to binder ratio were kept at 30% and 0.4 for all mixes, respectively. Strength development for the blended concretes was monitored until 91 days of curing, during which a modification of pore distribution was examined by mercury intrusion porosimetry. Simultaneously, the pozzolanic activity was evaluated by the content of calcium hydroxide (CH) in the cement pastes obtained from results of thermogravimetry analysis, and the phase composition of the specimens was quantitatively determined X-ray diffraction with Rietveld refinement method. As a result, the CH content in the glass-mixed specimen was decreased with time after certain age depending on glass types. Also, OLED was much effective to the pozzolanic activity, producing a higher content of C-S-H gel at 91 days, compared to LCD. This phenomenon may be attributed to a difference of Al2O3 and SiO2 content in the oxide composition, which would induce a shift of larger pore to micropore resulting in an increase in the strength for OLED concrete.

Similar content being viewed by others

References

Ahmaruzzaman M (2010) A review on the utilization of fly ash. Progress in Energy and Combustion Science 36(3):327–363, DOI: 10.1016/j.pecs.2009.11.003

Aiqin W, Chengzhi Z, Mingshu T, Ningsheng Z (1999) ASR in mortar bars containing silica glass in combination with high alkali and high fly ash contents. Cement and Concrete Composites 21:375-381, DOI:10.1016/S0958-9465(99)00020-7

Aligizaki KK (2006) Pore structure of cement-based materials - Testing, interpretation and requirements. Taylor & Francis, Abingdon, UK

Barbhuiya SA, Gbagbo JK, Russell MI, Basheer PA (2009) Properties of fly ash concrete modified with hydrated lime and silica fume. Construction and Building Materials 23(10):3233–3239, DOI: 10.1016/ j.conbuildmat.2009.06.001

Bignozzi MC, Saccani A, Barbieri L, Lancellotti I (2015) Glass waste as supplementary cementing materials: The effects of glass chemical composition. Cement and Concrete Composites 55:45–52, DOI: 10.1016/j.cemconcomp.2014.07.020

Carsana M, Frassoni M, Bertolini L (2014) Comparison of ground waste glass with other supplementary cementitious materials. Cement and Concrete Composites 45:39-45, DOI: 10.1016/j.cemconcomp.2013. 09.005

Chen G, Lee H, Young KL, Yue PL, Wong A, Tao T, Choi KK (2002) Glass recycling in cement production - An innovative approach. Waste Management 22(7):747–800, DOI: 10.1016/S0956-053X(02)00047-8

Coffey VC (2017) The age of OLED displays. Optics & Photonics News 28(11):34–41

Du H, Tan KH (2014) Waste glass powder as cement replacement in concrete. Journal of Advanced Concrete Technology 12(11):468–477, DOI: 10.3151/jact.l2.468

Dyer TD, Dhir RK (2001) Chemical reactions of glass cullet used as cement component. Journal of Materials in Civil Engineering 13(6):412–417, DOI: 10.1061/(ASCE)0899-1561(2001)13:6(412)

Hsiao CT, Chang PL, Chen CW, Huang HH (2011) A systems view for the high-tech industry development: A case study of large-area TFT- LCD industry in Taiwan. Asian Journal of Technology Innovation 19(1):117–132, DOI: 10.1080/19761597.2011.578422

Idir R, Cyr M, Tagnit-Hamou A (2011) Pozzolanic properties of fine and coarse color-mixed glass cullet. Cement and Concrete Composites 33(1):19–28, DOI: 10.1016/j.cemconcomp.2010.09.013

Islam GMS, Rahman MH, Kazi Nayem (2017) Waste glass powder as partial replacement of cement for sustainable concrete practice. International Journal of Sustainable Built Environment 6(1):37–44, DOI: 10.1016/j.ijsbe.2016.10.005

Ismail ZZ, Al-Hashmi EA (2009) Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Management 29(2):655–664, DOI: 10.1016/j.wasman.2008.08.012

Jani Y, Hogland W (2014) Waste glass in the production of cement and concrete - A review. Journal of Environmental Chemical Engineering 2(3):1767–1775, DOI: 10.1016/j.jece.2014.03.016

Kim J, Choi YC, Choi S (2018) Fractal characteristics of pore structures in GGBFS-based cement pastes. Applied Surface Science 428:304–314, DOI: 10.1016/j.apsusc.2017.09.165

Kim K, Kim K, Hwang J (2015) LCD waste glass as a substitute for feldspar in the porcelain sanitary ware production. Ceramics International 41(5):7097–7102, DOI: 10.1016/j.ceramint.2015.02.018

KS F 2405 (2010) Standard test method for compressive strength of concrete. KS F 2405, Korea Standards Association, Seoul, Korea (in Korean)

KS F 2527 (2016) Standard test method for compressive strength of concrete. KS F 2527, Korea Standards Association, Seoul, Korea (in Korean)

KS L 5201 (2006) Portland cement. KS L 5201, Korea Standards Association, Seoul, Korea (in Korean)

Liu G, Florea MVA, Brouwers HJH (2019) Performance evaluation of sustainable high strength mortars incorporating high volume waste glass as binder. Construction and Building Materials 202:574–588, DOI:10.1016/j.conbuildmat.2018.12.110

Luan Y, Ishida T, Nawa T, Sagawa T (2012) Enhanced model and simulation of hydration process of blast furnace slag in blended cement. Journal of Advanced Concrete Technology 10(1):1–13, DOI: 10.3151/ jact.10.1

Maraghechi H, Maraghechi M, Rajabipour F, Pantano CG (2014) Pozzolanic reactivity of recycled glass powder at elevated temperatures: Reaction stoichiometry, reaction products and effect of alkali activation. Cement and Concrete Composites 53:105-114, DOI: 10.1016/j.cemconcomp.2014.06.015

Mehta PK, Monteiro PJM (2014) Concrete - Microstructure, properties, and materials, 4th edition. McGraw Hill Education, New York, NY, USA

Neville AM (2011) Properties of concrete, 5th edition. Prentice Hall, Upper Saddle River, NJ, USA

Park SB, Lee BC (2004) Studies on expansion properties in mortar containing waste glass and fibers. Cement and Concrete Research 34(7):1145–1152, DOI: 10.1016/j.cemconres.2003.12.005

Poon CS, Lam L, Wong YL (2000) A study on high strength concrete prepared with large volumes of low calcium fly ash. Cement and Concrete Research 30(3):447–455, DOI: 10.1016/S0008-8846(99)00271-9

Rashad AM (2015) Recycled cathode ray tube and liquid crystal display glass as fine aggregate replacement in cementitious materials. Construction and Building Materials 93:1236-1248, DOI: 10.1016/j.conbuildmat.2015.05.004

Saha AK (2018) Effect of class F fly ash on the durability properties of concrete. Sustainable Environment Research 28(1):25–31, DOI: 10.1016/j.serj.2017.09.001

Sahmaran M, Yaman 10, Tokyay M (2009) Transport and mechanical properties of self consolidating concrete with high volume fly ash. Cement and Concrete Composites 31(2):99–106, DOI: 10.1016/j.cemconcomp.2008.12.003

Shao Y, Lefort T, Moras S, Rodriguez D (2000) Studies on concrete containing ground waste glass. Cement and Concrete Research 30(1):91–100, DOI: 10.1016/S0008-8846(99)00213-6

Tang CW (2018) Properties of fired bricks incorporating TFT-LCD waste glass powder with reservoir sediments. Sustainability 10(7):2503, DOI: 10.3390/sul 0072503

Toby BH (2006) R factors in rietveld analysis: How good is good enough? Powder Diffraction 21(1):67–70, DOI: 10.1154/1.2179804

Wang CC, Wang HY (2017) Assessment of the compressive strength of recycled waste LCD glass concrete using the ultrasonic pulse velocity. Construction and Building Materials 137:345-353, DOI: 10.1016/ j.conbuildmat.2017.01.117

Zeng Q, Li K, Fen-Chong T, Dangla P (2010) Surface fractal analysis of pore structure of high-volume fly-ash cement pastes. Applied Surface Science 257(3):762–768, DOI: 10.1016/j.apsusc.2010.07.061

Zheng K (2013) Recycled glass concrete. In: Eco-efficient concrete. Woodhead Publishing, Sawston, UK, 241–270

Acknowledgements

This research was supported by a grant (19CTAP-C152028-02) from Technology Advancement Research Program funded by Ministry of Land, Infrastructure and Transport of Korean government.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, SK., Jang, IY. & Yang, HJ. Strength Development Characteristics of Concrete Replaced with Different Waste Glasses from Display Industry as a Cementitious Material. KSCE J Civ Eng 24, 2485–2494 (2020). https://doi.org/10.1007/s12205-020-0223-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-020-0223-y