Abstract

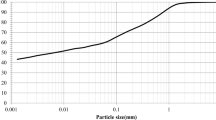

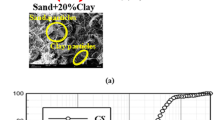

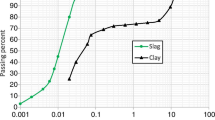

Cutter soil mixing (CSM) is a fairly new technique for shallow to deep soil stabilisation that mostly uses cement based slurry to improve the in-situ properties of soft soils. This research aims to experimentally investigate the effect of the depth of cutter soil mixing on the compressive strength of a saturated soft clay treated with alkali-activated slag slurry. Various percentages of additives were added to the saturated soft clay to increase the compressive strength and to make it suitable for constructing shallow to deep CSM panels as earth retaining walls that are used for excavations. Several high-pressure curing apparatuses were used to simulate insitu field stress due to the depth/weight of CSM panels. Then a set of compressive strength tests were conducted to investigate the effect of different curing pressures, additives content and curing time on the compressive behavior and strength of CSM panels. Microstructural studies were also performed to understand the reactions of the mixtures. The results showed that the compressive behavior of CSM panel changes significantly by increasing the mixing depth. Moreover the influence of curing pressure equivalent to the depth of CSM panels on increasing unconfined compressive strength of specimens is partially more than the effect of additives and considerably more than the effect of curing time. The microstructural studies also showed that the main hydration products are cementitious products such as calcium silicate hydrates (C-S-H) and the addition of alkali-activated slag in a treated clay results in production of the cementitious products in a faster rate.

Similar content being viewed by others

References

Arslan, H., Sture, S., and Batiste, S. (2008). “Experimental simulation of tensile behavior of lunar soil simulant JSC-1.” Materials Science and Engineering A, Vol.478, pp.201–207, DOI: https://doi.org/10.1016/j.msea.2007.05.113.

Arulrajah, A., Mohammadinia, A., D’Amico, A., and Horpibulsuk, S. (2017). “Effect of lime kiln dust as an alternative binder in the stabilization of construction and demolition materials.” Construction and Building Materials, Vol. 152, pp. 999–1007, DOI: https://doi.org/10.1016/j.conbuildmat.2017.07.070.

ASTM (1999). Standard test method for using ph to estimate the soillime proportion requirement for soil stabilization, D6276 - 99a, ASTM International, West Conshohocken, PA, USA.

ASTM (2016). Standard Test method for unconfined compressive strength of cohesive soil, D2166/D2166M-16, ASTM International, West Conshohocken, PA, USA, DOI: 10.1520/D2166_D2166M-16.

Bakharev, T., Sanjayan, J. G., and Cheng, Y.-B. (1999). “Alkali activation of Australian slag cements.” Cement and Concrete Research, Vol. 29, No. 1, pp. 113–120, DOI: https://doi.org/10.1016/S0008-8846(98)00170-7.

BAUER Maschinen GmbH (2016). Process description manual: Cutter soil mixing process and equipment, No. 905.656.2, BAUER Foundation Corp., Odessa, FL, USA.

Bellato, D., Simonini, P., Grisolia, M., Leder, E., and Marzano, I. P. (2013). “Quality control of cutter soil mixing (CSM) technology - A case study.” Proc. of The 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France.

Bellato, D., Simonini, P., Marzano, I. P., Leder, E., Grisolia, M., Vohs, T., and Gerressen, F. W. (2012). Mechanical and physical properties of a CSM cut-off/retaining wall, ICGI 2012 - International Conference on Ground Improvement and Ground Control, Wollongong, Australia.

Benhelal, E., Zahedi, G., Shamsaei, E., and Bahadori, A. (2013). “Global strategies and potentials to curb CO2 emissions in cement industry.” Journal of Cleaner Production, Vol. 51, pp. 142–161, DOI: https://doi.org/10.1016/j.jclepro.2012.10.049.

Bhadriraju, V., Puppala, A. J., Madhyannapu, R. S., and Williammee, R. (2008). “Laboratory procedure to obtain well-mixed soil binder samples of medium stiff to stiff expansive clayey soil for deep soil mixing simulation.” Geotchnical Testing Journal, Vol. 31, No. 3, pp. 225–238, DOI: https://doi.org/10.1520/GTJ100936.

Bjergea, L.-M. and Brevikb, P. (2014). “CO2 capture in the cement industry, norcem CO2 Capture Project (Norway).” Energy Procedia, Vol. 63, pp 6455–6463, DOI: https://doi.org/10.1016/j.egypro.2014.11.680.

Bruce, D. A. (2009). Seepage cut-offs for levees and dams: The technology review, Dam Safety Annual Conference, Florida, USA.

Bruce, M. E. C., Berg, R. R., Collin, J. G., Filz, G. M., Terashi, M., and Yang, D. S. (2013). Federal highway administration design manual: Deep mixing for embankment and foundation support, No. FHWAHRT-13-046, Department of Transportation, Washington, D.C., USA.

Brunner, W., Fiorotto, R., Stötzer, E., and Schöpf, M. (2006). “The innovative CSM-cutter soil mixing for constructing retaining and cut-off walls.” Proc. of GeoCongress 2006, Atlanta, Georgia, USA, DOI: https://doi.org/10.1061/9780784408032.

Building Research Establishment (2002). Development of Design and Construction Methods to Stabilise Soft Organic Soils (EP. 60), IHS BRE Press. Watford, UK, p. 96.

CDIT (2002). The deep mixing method: Principle, design and construction (1st Ed.), Balkema, Netherlands, p. 123, ISBN: 9058093670.

Chai, J. and Carter, J. P. (2011). Deformation analysis in soft ground improvement, Springer, Heidelberg, Germany p. 247

Chaparro, W. A., Bastidas, D. M., and Bautista-Ruiz, J. H. (2012). “Mechanical properties and absorption of chlorides in alkali activated sag concrete and exposed to carbonation.” Revista Facultad de Ingeniería Universidad de Antioquia, Vol. 62, pp. 189–195.

Chen, W. and Brouwers, H. J. H. (2007). “The hydration of slag, Part 1: Reaction models for alkali-activated slag.” Journal of Materials Science, Vol. 42, pp. 428–443, DOI: https://doi.org/10.1007/s10853-006-0873-2.

Consoli, N. C., de Moraes, R. R., and Festugato, L. (2013). “Parameters controlling tensile and compressive strength of fiber-reinforced cemented soil.” Journal of Materials in Civil Engineering, Vol. 25, No. 10, pp. 1568–1573, DOI: https://doi.org/10.1061/(ASCE)MT.1943-5533.0000555.

Correia, A. G., Winter, M. G., and Puppala, A. J. (2016). “A review of sustainable approaches in transport infrastructure geotechnics.” Transportation Geotechnics, Vol. 7, pp. 21–28, DOI: https://doi.org/10.1016/j.trgeo.2016.03.003.

Denies, N., Huybrechts, N., De Cock, F., Lameire, B., Maertens, J., bvba, J. M., and Leuven, K. (2012). “Soil mix walls as retaining structures - Belgian practice.” International Symposium on Ground Improvement, Brussels, Belgium.

Faraone, N., Tonello, G., Furlani, E., and Maschio, S. (2009). “Steelmaking slag as aggregate for mortars: Effects of particle dimension on compression strength.” Chemosphere, Vol. 77, pp. 1152–1156, DOI: https://doi.org/10.1016/j.chemosphere.2009.08.002.

Farouk, A. and Shahien, M. M. (2013). “Ground improvement using soil-cement columns: Experimental investigation.” Alexandria Engineering Journal, Vol. 52, pp. 733–740, DOI: https://doi.org/10.1016/j.aej.2013.08.009.

Frikhan, W., Tounekti, F., Kaffel, W., and Bouassida, M. (2014). “Experimental study for the mechanical characterization of tunis soft soil reinforced by a group of sand columns.” Soil and Foundations, Vol. 55, No. 1, pp. 181–191, DOI: https://doi.org/10.1016/j.sandf.2014.12.014.

Gerressen, F. and Vohs, T. (2012). “CSM worldwide experiences of a young soil mixing method.” Proc. of the 4th International Conference on Grouting and Deep Mixing, New Orleans, Louisiana, USA, DOI: https://doi.org/10.1061/9780784412350.

Ghiabi, H. and Selvadurai, A. P. S. (2006). “Laboraory testing of a soft silty cay.” Proc. of the 4th International Conference on Soft Soil Engineering, Vancouver, Canada.

Grubeša, I. N., Barišic, I., Fucic, A., and Bansode, S. S. (2016). Characteristics and uses of steel slag in building construction, Elsevier, Amsterdam, Netherlands, p. 194.

Güllü, H., Canakci, H., and Al Zangana, I. F. (2017). “Use of cement based grout with glass powder for deep mixing.” Construction and Building Materials, Vol. 137, pp. 12–20, DOI: https://doi.org/10.1016/j.conbuildmat.2017.01.070.

Han, J. (2015). Principles and practices of ground improvement, John Wiley and Sons, Hoboken, New Jersey, USA, p. 432.

Imbabi, M. S., Carrigan, C., and McKenna, S. (2012). “Trends and developments in green cement and concrete technology.” International Journal of Sustainable Built Environment, Vol. 1, No. 2, pp. 194–216, DOI: https://doi.org/10.1016/j.ijsbe.2013.05.001.

Indraratna, B., Chu, J., and Rujikiatkamjorn, C. (2015). Ground improvement case histories (chemical, electrokinetic, thermal and bioengineering), Elsevier, Amsterdam, Netherlands, p. 724.

James, R., Kamruzzaman, A. H. M., Haque, A., and Wilkinson, A. (2008). “Behaviour of lime-slag-treated clay.” Proc. The Institution of Civil Engineers - Ground Improvement, Vol. 161, No. 4, pp. 207–216, DOI: https://doi.org/10.1680/grim.2008.161.4.207.

Jamsawanga, P., Nuansrithongb, N., Voottipruexc, P., Songpiriyakijd, S., and Jongpradiste, P. (2017). “Laboratory investigations on the swelling behavior of composite expansive clays stabilized with shallow and deep clay-cement mixing methods.” Applied Clay Science, Vol. 148, pp. 83–94, DOI: https://doi.org/10.1016/j.clay.2017.08.013.

Kamruzzaman, A. H. M., Chew, S. H., and Lee, F. H. (2006). “Microstructure of cement-treated Singapore marine clay.” Proc. The Institution of Civil Engineers - Ground Improvement, Vol. 10, No. 3, pp. 113–123, DOI: https://doi.org/10.1680/grim.2006.10.3.113.

Karima, M. R., Zaina, M. F. M., Jamila, M., Laib, F. C., and Islamc, M. N. (2011). “Use of wastes in construction industries as an energy saving approach.” Energy Procedia, Vol. 12, pp. 915–919, DOI: https://doi.org/10.1016/j.egypro.2011.10.120.

Keramatikerman, M., Chegenizadeh, A., and Nikraz, H. (2016). “Effect of GGBFS and lime binders on the engineering properties of clay.” Applied Clay Science, Vol. 132–133, pp. 722–730, DOI: https://doi.org/10.1016/j.clay.2016.08.029.

Kitazume, M. and Terashi, M. (2017). The deep mixing method, CRC press, Boca Raton, Florida, USA, p. 410.

Kogbara, R. B. and Al-Tabbaa, A. (2011). “Mechanical and leaching behaviour of slag-cement and lime-activated slag stabilised/solidified contaminated soil.” Science of the Total Environment, Vol. 409, pp. 2325–2335, DOI: https://doi.org/10.1016/j.scitotenv.2011.02.037.

Korff, M. (2013). Response of piled buildings to the construction of deep excavations, University of Cambridge, Cambridge, UK, DOI: https://doi.org/10.17863/CAM.14043.

Lapointe, E. (2012). Cement-treated soil: A comparison of laboratory and field data from foundation slide remediation deep mixing project, PhD Thesis, University of British Columbia, BC, Canada, DOI: https://doi.org/10.14288/1.0050910.

Locat, J., Bérubé, M. A., and Choquette, M. (1990). “Laboratory investigations on the lime stabilization of sensitive clays: Shear strength development.” Canadian Geotechnical Journal, Vol. 27, No. 3, pp. 294–304, DOI: https://doi.org/10.1139/t90-040.

Lopez, R. A., Majewski, A., and Harvey, T. (2009). Permanent excavation support in urban areas using cutter soil mixing technology, International Foundation Congress and Equipment Expo 2009, Orlando, Florida, United States, USA, DOI: https://doi.org/10.1061/41023(337)24.

Mathieu, F., Borel, S., and Lefebvre, L. (2006). “CSM: An innovative solution for mixed-in-situ retaining walls, cut-off walls and soil improvement.” 10th International Conference on Piling and Deep Foundations, Amsterdam, Netherlands.

Mingtang Chai, Hu Zhang, Jianming Zhang, and Zhang, Z. (2017). “Effect of cement additives on unconfined compressive strength of warm and ice-rich frozen soil.” Construction and Building Materials, Vol. 149, pp. 861–868, DOI: https://doi.org/10.1016/j.conbuildmat.2017.05.202.

Nicholson, P. G. (2015). Soil improvement and ground modification method (1st Ed.), Elsevier, Amsterdam, Netherlands, p. 472.

Nidzam, R. M. and Kinuthia, J. M. (2010). “Sustainable soil stabilisation with blastfurnace slag - A review.” Proc. The Institution of Civil Engineers - Construction Materials, Vol. 163, No. 3, pp. 157–168, DOI: https://doi.org/10.1680/coma.2010.163.3.157.

Oliveira, P. J. V., Pinheiro, J. L. P., and Correia, A. A. S. (2011). “Numerical analysis of an embankment built on soft soil reinforced with deep mixing columns: Parametric study.” Computers and Geotechnics, Vol. 38, pp. 566–576, DOI: https://doi.org/10.1016/j.compgeo.2011.03.005.

Ouda, A. S. and Abdel-Gawwad, H. A. (2015). “The effect of replacing sand by iron slag on physical, mechanical and radiological properties of cement mortar.” HBRC Journal, Vol. 13, No. 3, pp. 255–261, DOI: https://doi.org/10.1016/j.hbrcj.2015.06.005.

Pakbaz, M. S. and Farzi, M. (2015). “Comparison of the effect of mixing methods (dry vs. wet) on mechanical and hydraulic properties of treated soil with cement or lime.” Applied Clay Science, Vol. 105–106, pp. 156–169, DOI: https://doi.org/10.1016/j.clay.2014.11.040.

Parmantier, D. M., Stow, R. F. P., and Byrne, R. J. (2009). Case study: Cement-bentonite pre-trenching and cutter soil mixing (CSM) for temporary shoring and groundwater cutoff, International Foundation Congress and Equipment Expo 2009, Orlando, Florida, DOI: https://doi.org/10.1061/41023(337)20.

Proctor, D. M., Fehling, K. A., Shay, E. C., Wittenborn, J. L., Green, J. J., Avent, C., and Zak, M. A. (2000). “Physical and chemical characteristics of blast furnace, basic oxygen furnace, and electric arc furnace steel industry slags.” Enviromental Science and Technology, Vol. 34, No. 8, pp. 1576–1578, DOI: https://doi.org/10.1021/es9906002.

Rabbani, P. (2018). Simulation of the effect of cutter soil mixing (CSM) method on soil stabilzation, PhD Thesis, Arak Branch, Islamic Azad University, Arak, Iran.

Rabbani, P., Daghigh, Y., Atrechian, M. R., Karimi, M., and Tolooiyan, A. (2012). “The potential of lime and grand granulated blast furnace slag (GGBFS) mixture for stabilisation of desert silty sands.” Journal of Civil Engineering Research, Vol. 2, No. 6, pp. 108–119, DOI: https://doi.org/10.5923/j.jce.20120206.07.

Sargent, P., Hughesb, P. N., and Rouainiac, M. (2016). “A new low carbon cementitious binder for stabilising weak ground conditions through deep soil mixing.” Soils and Foundations, Vol. 56, No. 6, pp. 1021–1134, DOI: https://doi.org/10.1016/j.sandf.2016.11.007.

Shalabi, F., Asi, I. M., and Qasrawi, H. Y. (2016). “Effect of by-product steel slag on the engineering properties of clay soils.” Journal of King Saud University - Engineering Sciences, Vol. 29, No. 4, pp. 394–399, DOI: https://doi.org/10.1016/j.jksues.2016.07.004.

Shao, Y., Macari, E. J., and Cai, W. (2005). “Compound deep soil mixing columns for retaining structures in excavations.” Journal of Geotechnical and Geoenvironmental Engineering, Vol. 131, No. 11, pp. 1370–1377, DOI: https://doi.org/10.1061/(ASCE)1090-0241(2005)131:11(1370).

Sikoraa, Z. and Ossowskia, R. (2013). “Geotechnical aspects of dike construction using soil-ash composites.” Procedia Engineering, Vol. 57, pp. 1029–1037, DOI: https://doi.org/10.1016/j.proeng.2013.04.130.

Small, J. C. (2016). Geomechanics in soil, rock, and environmental engineering, CRC Press, Boca Raton, Florida, USA, p. 541.

Tasong, W. A., Wild, S., and Tilley, R. J. D. (1999). “Mechanisms by which ground granulated blastfurnace slag prevents sulphate attack of lime-stabilised kaolinite.” Cement and Concrete Research, Vol. 29, No. 7, pp. 875–982, DOI: https://doi.org/10.1016/S0008-8846(99)00007-1.

Terzaghi, K., Peck, R. B., and Mesri, G. (1996). Soil mechanics in engineering practice (3rd Ed.), Wiley, Hoboken, New Jersey, USA, p. 592.

Tolooiyan, A. and Gavin, K. (2011). “Modelling the cone penetration test in sand using cavity expansion and arbitrary lagrangian eulerian finite element methods.” Computers and Geotechnics, Vol. 38, pp. 482–490, DOI: https://doi.org/10.1016/j.compgeo.2011.02.012.

Wang, P. Z., Trettin, R., and Rudert, V. (2005). “Effect of fineness and particle size distribution of granulated blast-furnace slag on the hydraulic reactivity in cement systems.” Advances in Cement Research, Vol. 17, pp. 161–166, DOI: https://doi.org/10.1680/adcr.2005.17.4.161.

Wild, S., Kinuthia, J. M., Jones, G. I., and Higgins, D. D. (1998). “Effects of partial substitution of lime with ground granulated blast furnace slag (GGBS) on the strength properties of lime-stabilised sulphatebearing clay soils.” Engineering Geology, Vol. 51, No. 1, pp. 37–53, DOI: https://doi.org/10.1016/S0013-7952(98)00039-8.

Wild, S. and Tasong, W. A. (1999). “Influence of ground granulated blastfurnace slag on the sulphate resistance of lime-stabilized kaolinite.” Magazine of Concrete Research, Vol. 51, No. 4, pp. 247–254, DOI: https://doi.org/10.1680/macr.1999.51.4.247.

Wonglert, A. and Jongpradist, P. (2015). “Impact of reinforced core on performance and failure behavior of stiffened deep cement mixing piles.” Computers and Geotechnics, Vol. 69, pp. 93–104, DOI: https://doi.org/10.1016/j.compgeo.2015.05.003.

Xiaolin, Y. and Jiaa, B. (2012). “Analysis of excavating foundation pit to nearby bridge foundation.” Procedia Earth and Planetary Science, Vol. 5, pp. 102–106, DOI: https://doi.org/10.1016/j.proeps.2012.01.017.

Yao, K., Yao, Z., Song, X., Zhang, X., Huc, J., and Pan, X. (2016). “Settlement evaluation of soft ground reinforced by deep mixed columns.” International Journal of Pavement Research and Technology, Vol. 9, No. 6, pp. 460–465, DOI: https://doi.org/10.1016/j.ijprt.2016.07.003.

Yi, Y., Gu, L., and Liu, S. (2015). “Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag.” Applied Clay Science, Vol. 103, pp. 71–76, DOI: https://doi.org/10.1016/j.clay.2014.11.005.

Yi, Y., Liska, M., and Al-Tabbaa, A. (2014). “Properties of two model soils stabilized with different blends and contents of GGBS, MgO, Lime, and PC.” Journal of Materials in Civil Engineering, Vol. 26, No. 2, pp. 267–274, DOI: https://doi.org/10.1061/(ASCE)MT.1943-5533.0000806.

Yongfenga, D., Feia, J., and Qib, F. (2017). “Design method of bridge approach improved by deep mixing methods in highway engineering.” Procedia Engineering, Vol. 189, pp. 365–371, DOI: https://doi.org/10.1016/j.proeng.2017.05.058.

Yusuf, M. O., Johari, M. A. M., Ahmad, Z. A., and Maslehuddin, M. (2014). “Evolution of alkaline activated ground blast furnace slag-ultrafine palm oil fuel ash based concrete.” Materials and Design, Vol. 55, pp. 387–393, DOI: https://doi.org/10.1016/j.matdes.2013.09.047.

Acknowledgements

The first author wishes to acknowledge the support provided by Keyhan-Khak Soil Mechanic and Concrete Co., Karaj, Iran with the preparation of the equipment and help with laboratory testing for this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rabbani, P., Tolooiyan, A., Lajevardi, S.H. et al. The Effect of the Depth of Cutter Soil Mixing on the Compressive Behavior of Soft Clay Treated by Alkali-Activated Slag. KSCE J Civ Eng 23, 4237–4249 (2019). https://doi.org/10.1007/s12205-019-0335-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-019-0335-4