Abstract

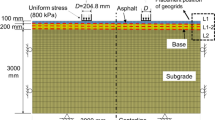

The effect of different configurations of normal contact stresses on the rutting performance of asphalt concrete overlays on a soft and stiff Crushed Aggregate Base (CAB) layer is investigated. A three-dimensional (3-D) finite element model of a pavement structure is generated. The effect of different types of simplified normal contact stresses and a realistic 3-D normal stress on the rutting performance is investigated. Since the failure mechanism of asphaltic materials at high temperature is mainly related to the flow of the material, the viscoelastic and viscoplastic constitutive relationships coupled with the hardening-relaxation mechanisms are utilized to represent the behavior of asphalt concrete layer. This constitutive relationship is part of the PANDA (Pavement Analysis using Nonlinear Damage Approach) model developed by the authors and their collaborators. As the result of simulation, the magnitude of the rut depth on the asphalt concrete layer is generally determined to be inversely proportional to the stiffness of the CAB layer, and the rut depth on the asphalt concrete layer under the realistic 3-D normal stress is about 1.5 times greater than the rut depth under uniformly distributed normal stress.

Similar content being viewed by others

References

Abu Al-Rub, R. K., Darabi, M. K., Little, D. N., and Masad, E. A. (2010). “A micro-damage healing model that improves prediction of fatigue life in asphalt mixes.” International Journal of Engineering Science, vol. 48, no. 11, pp. 966–990, DOI: 10.1016/j.ijengsci. 2010.09.016.

Cao, W. and Kim, Y. R. (2016). “A viscoplastic model for the confined permanent deformation of asphalt concrete in compression.” Mech. Mater., vol. 92, pp. 235–247, DOI: 10.1016/j.mechmat.2015.10.001.

Chen, F., Balieu, R., and Kringos, N. (2017). “Thermodynamics-based finite strain viscoelastic-viscoplastic model coupled with damage for asphalt material.” Int. J. Solids Struct., vol. 129, pp. 61–73, DOI: 10.1016/j.ijsolstr.2017.09.014.

Cho, Y., McCullough, B. F., and Weissmann, J. (1996). “Considerations on finite-element method application in pavement structural analysis.” Transportation Research Board, Washington, D.C., vol. 1539, pp. 96–101, DOI: 10.3141/1539-13.

Coleri, E., Harvey, J. T., Yang, K., and Boone, J. M. (2012). “Development of a micromechanical finite element model from computed tomography images for shear modulus simulation of asphalt mixtures.” Constr. Build Mater., vol. 30, pp. 783–793, DOI: 10.1016/j.conbuildmat. 2011.12.071.

Darabi, M. K., Abu Al Rub, R. K., Masad, E., Huang, C. W., and Little, D. (2012b). “A modified viscoplastic model to predict the permanent deformation of asphaltic materials under cyclic-compression loading at high temperatures.” International Journal of Plasticity, vol. 35, pp. 100–134, DOI: 10.1016/j.ijplas.2012.03.001.

Darabi, M. K., Abu Al-Rub, R. K., Masad, E. A., and Little, D. N. (2012a). “A thermodynamic framework for constitutive modeling of time-and rate-dependent materials, Part ii: Numerical aspects and application to asphalt concrete.” International Journal of Plasticity, vol. 35, pp. 67–99, DOI: 10.1016/j.ijplas.2012.02.003.

Darabi, M. K., Abu Al-Rub, R. K., Masad, E. A., and Little, D. N. (2013). “Cyclic hardening-relaxation viscoplasticity model for asphalt concrete materials.” J Eng Mech, vol. 139, no. 7, pp. 832–847, DOI: 10.1061/(ASCE) EM.1943-7889.0000541.

Darabi, M. K., Abu Al-Rub, R. K., Masad, E. A., Huang, C. W., and Little, D. N. (2011). “A thermo-viscoelastic-viscoplastic-viscodamage constitutive model for asphaltic materials.” Int. J. Solids Struct., vol. 48, no. 1, pp. 191–207, DOI: 10.1016/j.ijsolstr.2010.09.019.

Dave, E. V., Paulino, G. H., and Buttlar, W. G. (2010). “Asphalt pavement aging and temperature dependent properties through a functionally graded viscoelastic model, Part-i: Development, implementation and verification.” in: Kawasaki, A., Kumakawa, A., Niino, M. (Eds.), Multiscale, multifunctional and functionally graded materials,Trans Tech Publications Ltd, Stafa, Zurich, pp. 47–52.

Drakos, C. A., Roque, R., and Birgisson, B. (2001). “Effects of measured tire contact stresses an near-surface rutting.” Assessing and Evaluating Pavements, pp. 59–69, DOI: 10.3141/1764-07.

Epps, J., Petersen, J. C., Kennedy, T. W., Anderson, D., and Haas, R. (1986). “Chemistry, rheology, and engineering properties of manganesetreated asphalts and asphalt mixtures.” Transport. Res. Rec., vol. 1096, pp. 106–119, http://worldcat.org/isbn/309041163.

Gibson, N., Qi, X., Shenoy, A., Al-Khateeb, G., Kutay, M. E., Andriescu, A., Stuart, K., Youtcheff, J., and Harman, T. (2012). Full-scale accelerated performance testing for superpave and structural validation, FHWA-HRT-11-045.

Huang, C. W. (2008). Development and numerical implementation of nonlinear viscoelastic-viscoplastic model for asphalt materials, Ph.D. Dissertation, Texas A&M University, http://hdl.handle.net/1969.1/ETD-TAMU-3137.

Huang, C. W., Abu Al Rub, R. K., Masad, E. A., Little, D., and Airey, G. (2011). “Numerical implementation and validation of a nonlinearviscoelastic and viscoplastic model for asphalt concrete mixes.” International Journal of Pavement Engineering, vol. 12, no. 4, pp. 433–447, DOI: 10.1080/10298436.2011.574137.

Huang, C. W., Masad, E., Muliana, A. H., and Bahia, H. (2007). “Nonlinearly viscoelastic analysis of asphalt mixes subjected to shear loading.” Mechanics of Time-Dependent Materials, vol. 11, no. 2, pp. 91–110, DOI: 10.1007/s11043-007-9034-5.

Kim, Y. R., Allen, D. H., and Little, D. N. (2007). “Computational constitutive model for predicting nonlinear viscoelastic damage and fracture failure of asphalt concrete mixtures.” International Journal of Geomechanics, vol. 7, no. 2, pp. 102–110, DOI: 10.1061/(ASCE)1532-3641(2007)7:2(102).

Kim, Y. R., Baek, C., Underwood, B. S., Subramanian, V., Guddati, M. N., and Lee, K. (2008). “Application of viscoelastic continuum damage model based finite element analysis to predict the fatigue performance of asphalt pavements.” KSCE J. Civ. Eng., vol. 12, no. 2, pp. 109–120, DOI: 10.1007/s12205-008-0109-x.

Krishnan, J. M. and Rajagopal, K. R. (2004). “Thermodynamic framework for the constitutive modeling of asphalt concrete: Theory and applications.” Journal of Materials in Civil Engineering (ASCE), vol. 16, no. 2, pp. 155–166, DOI: 10.1061/(ASCE)0899-1561(2004) 16:2(155).

Lee, H. J., Daniel, J. S., and Kim, Y. R. (2000). “Continuum damage mechanics-based fatigue model of asphalt concrete.” J. Mater Civil Eng., vol. 12, no. 2, pp. 105–112, DOI: 10.1061/(ASCE)0899-1561(2000) 12:2(105).

Liu, Y., Dai, Q. L., and You, Z. P. (2009). “Viscoelastic model for discrete element simulation of asphalt mixtures.” J. Eng. Mech.-ASCE, vol. 135, no. 4, pp. 324–333, DOI: 10.1061/(ASCE)0733-9399(2009)135:4(324).

Lu, Y. and Wright, P. J. (1998). “Numerical approach of visco-elastoplastic analysis for asphalt mixtures.” Computers & Structures, vol. 69, no. 2, pp. 139–147, DOI: 10.1016/S0045-7949(98)00139-4.

Masad, E., Dessouky, S., and Little, D. (2007). “Development of an elastoviscoplastic microstructural-based continuum model to predict permanent deformation in hot mix asphalt.” International Journal of Geomechanics, vol. 7, no. 2, pp. 119–130, DOI: 10.1061/(ASCE) 1532-3641(2007)7:2(119).

Masad, E., Huang, C. W., Airey, G., and Muliana, A. (2008). “Nonlinear viscoelastic analysis of unaged and aged asphalt binders.” Constr Build Mater, vol. 22, no. 11, pp. 2170–2179, DOI: 10.1016/j.conbuildmat. 2007.08.012.

Masad, E., Tashman, L., Little, D., and Zbib, H. (2005). “Viscoplastic modeling of asphalt mixes with the effects of anisotropy, damage and aggregate characteristics.” Mech Mater, vol. 37, no. 12, pp. 1242–1256, DOI:10.1016/j.mechmat.2005.06.003.

Misra, A., Singh, V., and Darabi, M. K. (2017). “Asphalt pavement rutting simulated using granular micromechanics-based rate-dependent damage-plasticity model.” International Journal of Pavement Engineering, pp. 1–14, DOI: 10.1080/10298436.2017.1380804.

Myers, L., Roque, R., Ruth, B., and Drakos, C. (1999). “Measurement of contact stresses for different truck tire types to evaluate their influence on near-surface cracking and rutting.” Transportation Research Record: Journal of the Transportation Research Board, vol. 1655, pp. 175–184, DOI: 10.3141/1655-23.

Novak, M., Birgisson, B., and Roque, R. (2003). “Tire contact stresses and their effects on instability rutting of asphalt mixture pavements-three-dimensional finite element analysis.” Transport. Res. Rec., vol. 1853, pp. 150–156, DOI: 10.3141/1853-17.

Perzyna, P. (1971). “Thermodynamic theory of viscoplastcity.” Advances in Applied Mechanics, vol. 11, pp. 313–354, DOI: 10.1016/S0065-2156(08)70345-4.

Rushing, J. F., Darabi, M. K., Rahmani, E., and Little, D. N. (2017). “Comparing rutting of airfield pavements to simulations using pavement analysis using nonlinear damage approach (panda).” International Journal of Pavement Engineering, vol. 18, no. 2, pp. 138–159, DOI: 10.1080/10298436.2015.1039007.

Schapery, R. A. (1969). “On the characterization of nonlinear viscoelastic materials.” Polymer Engineering & Science, vol. 9, no. 4, pp. 295–310, DOI: 10.1002/pen.760090410.

Shahsavari, H., Naghdabadi, R., Baghani, M., and Sohrabpour, S. (2016). “A viscoelastic-viscoplastic constitutive model considering damage evolution for time dependent materials: Application to asphalt mixes.” Int. J. Damage Mech., vol. 25, pp. 921–942, DOI: 10.1177/1056789516658506.

Siddharthan, R. V., Krishnamenon, N., El-Mously, M., and Sebaaly, P. E. (2002). “Investigation of tire contact stress distributions on pavement response.” J. Transp. Eng.-ASCE, vol. 128, no. 2, pp. 136–144, DOI: 10.1061/(ASCE)0733-947X(2002)128:2(136).

Souza, L. T., Kim, Y. R., Souza, F. V., and Castro, L. S. (2012). “Experimental testing and finite-element modeling to evaluate the effects of aggregate angularity on bituminous mixture performance.” J. Mater. Civil Eng., vol. 24, no. 3, pp. 249–258, DOI: 10.1061/(ASCE) MT.1943-5533.0000386.

Subramanian, V., Guddati, M. N., and Kim, Y. R. (2013). “A viscoplastic model for rate-dependent hardening for asphalt concrete in compression.” Mech Mater., vol. 59, pp. 142–159, DOI: 10.1016/j.mechmat.2012.10.003.

Tielking, J. T. (1992). “Conventional and wide base radial truck tyres.” The Third International Symposium on Heavy Vehicle Weights and Dimensions, Queen's College Cambridge, UK, pp. 182–190.

Varma, S. and Kutay, M. E. (2016). “Viscoelastic nonlinear multilayered model for asphalt pavements.” J. Eng. Mech., Vol. 142, No. 7, DOI: 10.1061/(ASCE)EM.1943-7889.0001095.

Wang, H. and Al-Oadi, I. L. (2009). “Combined effect of moving wheel loading and three-dimensional contact stresses an perpetual pavement responses.” Transport Res. Rec., pp. 53–61, DOI: 10.3141/2095-06.

Wang, H. and Al-Qadi, I. L. (2010). “Near-surface pavement failure under multiaxial stress state in thick asphalt pavement.” Transport Res. Rec., pp. 91–99, DOI: 10.3141/2154-08.

Wang, H., Al-Qadi, I. L., and Stanciulescu, I. (2010). Effect of friciton on rolling tire-pavement interactio, Report, NEXTRANS Project No 019PY01, Technical Summary, Purdue University.

Wang, H., Al-Qadi, I. L., Portas, S., and Coni, M. (2013). “Threedimensional finite element modeling of instrumented airport runway pavement responses.” Transport Res. Rec., pp. 76–83, DOI: 10.3141/2367-08.

Weissman, S. (1999). “Influence of tire-pavement contact stress distribution on development of distress mechanisms in pavements. Transportation Research Record.” Journal of the Transportation Research Board, vol. 1655, pp. 161–167, DOI: 10.3141/1655-21.

Zhu, H. R. and Sun, L. (2013). “Mechanistic rutting prediction using a two-stage viscoelastic-viscoplastic damage constitutive model of asphalt mixtures.” J. Eng. Mech., vol. 139, no. 11, pp. 1577–1591, DOI: 10.1061/(ASCE)EM.1943-7889.0000598.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, SM., Darabi, M.K., Little, D.N. et al. Effect of the Realistic Tire Contact Pressure on the Rutting Performance of Asphaltic Concrete Pavements. KSCE J Civ Eng 22, 2138–2146 (2018). https://doi.org/10.1007/s12205-018-4846-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-018-4846-1