Abstract

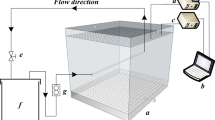

The purpose of this study is to design and develop an alternative moisture content device, based on infrared heating and Peltier dehumidifying. Infrared heating is an alternative heating method which is commonly used is industrial drying. Compared to the convective drying it has some advantages such as, short drying time, less energy consumption, uniform dispersion of the temperature, ease of control and space saving. Peltier elements are thermoelectrical ceramics which are widely used in industry for cooling and heating purposes. In this study, an instrument which allows the soil sample to fast-drying, and continuous recording of the mass of soil during drying, has been developed. Evaporation of the soil moisture is provided by an infrared heater. Mass change in the sample was measured by a load cell. To isolate from the room humidity, heating and weighing were done in a cabinet. A dry air circulation module has been improved, which allow humid air to dry in the Peltier condenser and send dried air back into the cabin. An electronic card was developed for automatic control and data logging. 27 soil samples were prepared at different water contents and were dried in both an oven and in the new device. Results showed that the water content values are in good agreement. Drying in new device has been completed within 10−25 min. Energy consumption is 90−97% less than that of the conventional oven.

Similar content being viewed by others

References

Aghbashlo, M. (2016). “Exergetic simulation of a combined infraredconvective drying process.” Heat Mass Transfer, Vol. 52, No. 4, pp. 829–844, DOI: 10.1007/s00231-015-1594-3.

Aktas, M., Sevik, S., Özdemir, M. B., and Gönen, E. (2015). “Performance analysis and modeling of a closed-loop heat pump dryer for bay leaves using artificial neural network.” Appl Therm Eng., Vol. 87, pp. 714–23, DOI: 10.1016/j.applthermaleng.2015.05.049.

Arsoy, S. (2008). “Temperature-controlled infrared drying characteristics of soils.” Drying Technology, Vol. 26, No. 12, pp. 1477–1483, DOI: 10.1080/07373930802412165.

ASHRAE (2016). ASHRAE handbook -Heating, ventilating, and airconditioning systems and equipment (I-P edition), American Society of. Heating, Refrigerating and Air-Conditioning Engineers, Atlanta, USA.

ASTM D2216–10 (2010). “Standard test methods for laboratory determination of water (moisture) content of soil and rock by Mass.” ASTM International, West Conshohocken, PA, USA.

ASTM D4318 (2000). “Standard test methods for liquid limit, plastic limit, and plasticity index of soils.” ASTM International, West Conshohocken, PA, USA.

ASTM D4643–08 (2008). “Standard test method for determination of water (moisture) content of soil by microwave oven heating.” ASTM International, West Conshohocken, PA, USA.

ASTM D4959–00 (2000). “Standard test method for determining of water (moisture) content of soil by the direct heating.” ASTM International, West Conshohocken, PA, USA.

ASTM D6913 (2009). “Standard test methods for particle-size distribution (gradation) of soils using sieve analysis.” ASTM International, West Conshohocken, PA, USA.

ASTM D7928 (2016). “Standard test method for particle-size distribution (gradation) of fine-grained soils using the sedimentation (hydrometer) analysis.” ASTM International, West Conshohocken, PA, USA.

ASTM D854 (2002). “Standard test method for specific gravity of soils.” ASTM International, West Conshohocken, PA, USA.

ASTM E74–13a (2013). “Standard practice of calibration of forcemeasuring instruments for verifying the force indication of testing machines.” ASTM International, West Conshohocken, PA, USA.

Astrain, D., Martinez, A., and Rodríguez, A. (2012). “Improvement of a thermoelectric and vapour compression hybrid refrigerator.” Applied Thermal Engineering, Vol. 39, pp. 140–150, DOI: 10.1016/j.applthermaleng.2012.01.054.

Brandão, R. J., Borel, L. D. M. S., Marques, L. G., Prado, M. M. (2016). “Heat and mass transfer, energy and product quality aspects in drying processes using infrared radiation.” Drying and Energy Technologies, J. M. P. Q. Delgado and A. G. B. de Lima, Springer, pp. 111–130.

Chang, Y. W., Chang, C. C., Ke, M. T., and Chen, S. L. (2009). “Thermoelectric air-cooling module for electronic devices.” Applied Thermal Engineering, Vol. 29, No. 13, pp. 2731–2737, DOI: 10.1016/j.applthermaleng.2009.01.004.

Ernest, S., Berney, I. V., Kyzar, J. D., and Oyelami, L. O. (2011). “Device comparison for determining field soil moisture content.” Geotechnical and Structures Laboratory, U.S. Army Engineer Research and Development Center, MS, USA, www.dtic.mil/dtic/tr/fwutext/u2/a552792.pdf.

Gilbert, P. A. (1974). “Evaluation of soil mechanics laboratory equipment, Report 13, feasibility study, microwave oven used for rapid determination of soil water contents.” Misc Paper No. 3–478. U.S. Army Engineer Waterways Experiment Station, Vicksbury, MS, USA.

Jarrett, P. M. (1983). “Testing of peats and organic soils.” ASTM STP 820, ASTM International, West Conshohocken, PA.

O’Kelly, B. C. (2004). “Accurate determination of moisture content of organic soils using the oven drying method.” Drying Technology, Vol. 22, pp. 1767–1776, DOI: 10.1081/DRT-200025642.

O’Kelly, B. C. (2005). “New method to determine the true water content of organic soils.” Geotechnical Testing Journal, Vol. 28, pp. 365–369, DOI: 10.1520/GTJ11963.

Rahman, S. M. A, Saidur, R., and Hawlader, M. N. A. (2013). “An economic optimization of evaporator and air collector area in a solar assisted heat pump drying system.” Energy Convers Manage, Vol. 76, pp. 377–84, DOI: 10.1016/j.enconman.2013.06.058.

Rawat, M. K., Chattopadhyay, H., and Neogi, S. (2013). “A review on developments of thermoelectric refrigeration and air conditioning systems: a novel potential green refrigeration and air conditioning technology.” International Journal of Emerging Technology and Advanced Engineering, Vol. 3, Special Issue 3, pp. 362–367.

Sevik, S. (2014). “Experimental investigation of a new design solar-heat pump dryer under the different climatic conditions and drying behaviour of selected products.” Solar Energy, Vol. 105, pp. 190–205, DOI: 10.1016/j.solener.2014.03.037.

Tan, F. L. and Fok, S. C. (2008). “Methodology on sizing and selecting thermoelectric cooler from different TEC manufacturers in cooling system design.” Energy Conversion and Management, Vol. 49, pp. 1715–1723, DOI: 10.1016/j.enconman.2007.11.001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dipova, N. Design and Development of Peltier Assisted Infrared Drying Based Soil Moisture Content Device. KSCE J Civ Eng 23, 29–36 (2019). https://doi.org/10.1007/s12205-018-0011-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-018-0011-0