Abstract

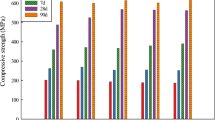

The utilization of pozzolans in cementitious system (concrete and mortar) minimizes both cost and energy. It also enhances mechanical strength and durability of the system. The total contribution of pozzolans can be categorized into two: (i) physical or filler effect which is attributed by the fineness of the particles and (ii) chemical or pozzolanic effect which is attributed by the pozzolanic reaction. It is difficult to quantify the strength development of cementitious system caused by the filler and pozzolanic effect separately. Therefore, the individual contribution of pozzolans in cementitious system because of its physical and chemical effects need to be profoundly understood by the scientific community. This paper reviews available literatures to understand the effect of non-reactive fillers that attributed as the microfiller effect of pozzolans in cementitious systems. The previous studies utilized chemically inactive materials that attributed only the microfiller activity of pozzolans for a partial replacement of cement. It was reported that filler effect is equal or sometimes more significant than pozzolanic effect in concrete. A larger range of replacement percentages (like 5%, 10%, 15% or 10%, 20%, 30% etc.) was used in the previous studies. However, probabilities of the optimum compressive strength because of the filler effect may lie in between two larger range of replacement percentages. Therefore, an experimental work is also carried out using natural ground sand of size 7.6-μm at a lower range of cement replacement percentages (like 2.5%, 5%, 7.5% etc.) in mortar. Compressive strength of mortar at different ages and microstructure analysis of mortar at 28 days were performed in this study. Test results showed that the filler effect is more pronounced at a lower replacement percentages of cement (0-10%) while using smaller non-reactive fillers. The maximum strength due to filler effect of ground sand is acheieved at 7.5% replacement of cement. Scanning Electron Microscope (SEM) images also confirmed the effect of fillers on the microstructure development of mortar.

Similar content being viewed by others

References

Agarwal, S. K. and Deepali, G. (2006). “Utilization of industrial wastes and unprocessed micro-fillers for making cost effective mortars.” Construction and Building Materials, Vol. 20, No. 10, pp. 999–1004, DOI: 10.1016/j.conbuildmat.2005.06.009.

Antiohos, S. K., Tapali, J. G., Zervaki, M., Coutinho, J. S., Tsimas, S., and Papadakis V. G. (2013). “Low embodied energy cement containing untreated RHA: A strength development and durability study.” Construction and Building Materials, Vol. 49, pp. 455–463, DOI: 10.1016/j.conbuildmat.2013.08.046.

ASTM C 150 (1994). Standard specification for portland cement, ASTM, Philadelphia, USA.

ASTM C109 (2009). “Standard test methods for compressive strength of hydraulic cement using 50 mm cube specimens.” Annual book of ASTM Standard, Vol. 4, No. 1, pp. 78–85, DOI: 10.1520/C0109_ C0109M-02.

BS EN196-1 (2005). Methods of testing cement, Part 1: Determination of strength, pp. 1–33.

Cheerarot, R., Tangpagasit, J., and Jaturapitakkul, C. (2004). “Compressive strength of mortars due to pozzolanic reaction of fly ash.” American Concrete Institute Journal, Vol. 221, pp. 411–426, DOI: 10.14359/13267.

Chindaprasirt, P., Homwuttiwong, S., and Jaturapitakkul, C. (2007). “Strength and water permeability of concrete containing palm oil fuel ash and rice husk-bark ash.” Construction and Building Materials, Vol. 21, No. 1, pp. 1492–1499, DOI: 10.1016/j.conbuildmat. 2006.06.015.

Chindaprasirt, P., Sinsiri, T., Kroehong, W., and Jaturapitakkul, C. (2014). “Role of filler effect and pozzolanic reaction of biomass ashes on hydrated phase and pore size distribution of blended cement paste.” Journal of Materials in Civil Engineering, Vol. 26, No. 9, DOI: 10.1061/(ASCE)MT.1943-5533.0000921.

Cordeiro, G. C., Romildo, D. T. F., Tavares, L. M., Fairbairn, E. M. R., and Hempel, S. (2011). “Influence of particle size and specific surface area on the pozzolanic activity.” Cement and Concrete Composites, Vol. 33, No. 5, pp. 529–534, DOI: 10.1016/j.cemconcomp.2011.02.005.

Cordeiro, G. C., Toledo Filho, R. D., Tavares, L. M., and Fairbairn, E. M. R. (2008). “Pozzolanic activity and fillers effect of sugarcane bagasse ash on Portland cement and lime mortars.” Cement and Concrete Composites, Vol. 30, No. 5, pp. 410–8, DOI: 10.1016/j.cemconcomp.2008.01.001.

De Sensale G. R. (2006). “Strength development of concrete with ricehusk ash.” Cement and Concrete Composites, Vol. 28, No. 2, pp. 158–160, DOI: 10.1016/j.cemconcomp.2005.09.005.

Detwiler, R. J. and Mehta, P. K. (1989). “Chemical and physical effects of silica fume on the mechanical behavior of concrete.” American Concrete Institute Journal, Vol. 86, No. 6, pp. 609–14, DOI: 10.14359/2281.

Givi, N. A., Rashid, S. A., Aziz, F. N. A., and Mohamad, S. M. A. (2010). “Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete.” Construction and Building Materials, Vol. 24, No. 11, pp. 2145–2150, DOI: 10.1016/j.conbuildmat.2010.04.045.

Goldman, A. and Bentur, A. (1993). “The influence of microfillers on enhancement of concrete strength.” Cement and Concrete Research, Vol. 23, No. 4, pp. 962–72, DOI: 10.1016/0008-8846(93)90050-J.

Goldman, A. and Bentur, A. (1994). “Properties of cementitious systems containing silica fume or nonreactive micro fillers.” Advanced Cement Based Materials, Vol. 1, No. 5, pp. 209–15, DOI: 10.1016/1065-7355(94)90026-4.

Ibrahim, R. K., Hamid, R., and Taha, M. R. (2014). “Strength and microstructure of mortar containing nano silica at high temperature.” ACI Materials Journal, Vol. 111, No. 2, pp. 163–170, DOI: 10.14359/51686497.

Isaia, G. C., GastaldiniA. L. G., and Morases, R. (2003). “Physical and pozzolanic action of mineral additions on the mechanical strength of high performance concrete.” Cement and Concrete Composites, Vol. 25, No. 1, pp. 69–76, DOI: 10.1016/S0958-9465(01)00057-9.

Jamil, M., Kaish, A. B. M. A., Raman, S. N., and Zain, M. F. M. (2013). “Pozzolanic contribution of rice husk ash in cementitious system.” Construction and Building Materials, Vol. 47, pp. 588–593, DOI: 10.1016/j.conbuildmat.2013.05.088.

Jaturapitakkul, C., Tangpagasit, J., Songmue, S., and Kiattikomol, K. (2011a). “Filler effect and pozzolanic reaction of ground palm oil fuel ash.” Construction and Building Materials, Vol. 25, No. 11, pp. 4287–4293, DOI: 10.1016/j.conbuildmat.2011.04.073.

Jaturapitakkul, C., Tangpagasit, J., Songmue, S., and Kiattikomol, K. (2011b). “Filler effect of fine particle sand on the compressive strength of mortar.” International Journal of Minerals, Metallurgy and Materials, Vol. 18, No. 2, pp. 240–246, DOI: 10.1007/s12613-011-0429-6.

Juenger, M. C. G. and Siddique, R. (2015). “Recent advances in understanding the role of supplementary cementitious materials in concrete.” Cement and Concrete Research (Available online 13 April 2015), DOI: 10.1016/j.cemconres.2015.03.018.

Karim, M. R., Hossain, M. M., Khan, M. N. N., Zain, M. F. M., Jamil, M., and Lai, F. C. (2014). “On the utilization of pozzolanic wastes as an alternative resource of cement.” Materials, Vol. 7, No. 12, pp. 7809–7827, DOI: 10.3390/ma7127809.

Karim, M. R., Zain, M. F. M., Jamil, M., and Lai, F. C. (2013). “Fabrication of a non-cement composite binder by using slag, palm oil fuel ash and rice husk ash with sodium hydroxide as an activator.” Construction and Building Materials, Vol. 49, pp. 894–902, DOI: 10.1016/j.conbuildmat.2013.08.077.

Kiattikomol, K., Jaturapitakkul, C., and Tangpagasit, J. (2000). “Effect of insoluble residue on properties of Portland cement.” Cement and Concrete Research, Vol. 30, No. 8, pp. 1209–14, DOI: 10.1016/S0008-8846(00)00315-X.

Kiattikomol, K., Jaturapitakkul, C., Songpiriyakijand, S., and Chutubtim, S. (2001). “A study of ground coarse fly ashes with different finenesses from varioussources as pozzolanicmaterials.” Cement and Concrete Composites, Vol. 23, No. 4–3, pp. 335–343, DOI: 10.1016/S0958-9465(01)00016-6.

Le, H. T., Kraus, M., Siewert, K., and Ludwig, H. M. (2015). “Effect of macro-mesoporous rice husk ash on rheological properties of mortar formulated from self-compacting high performance concrete.” Construction and Building Materials, Vol. 80, pp. 225–235, DOI: 10.1016/j.conbuildmat.2015.01.079.

Mohammed, M. K., Dawson, A. R., and Thom, N. H. (2013). “Production, microstructure and hydration of sustainable self-compacting concrete with different types of filler.” Construction and Building Materials, Vol. 49, pp. 84–92, DOI: 10.1016/j.conbuildmat.2013.07.107.

Rashad, A. M., Seleem, H. E. H., and Shaheen, A. F. (2014). “Effect of silica fume and slag on compressive strength and abrasion resistance of HVFA concrete.” International Journal of Concrete Structures and Materials, Vol. 8, No. 1, pp. 69–81, DOI: 10.1007/s40069-013-0051-2.

Rukzon, S. and Chindaprasirt, P. (2013). “Strength, porosity, and chloride resistance of mortar using the combination of two kinds of pozzolanic materials.” International Journal of Minerals, Metallurgy and Materials, Vol. 20, No. 8, pp. 808–814, DOI: 10.1007/s12613-013-0800-x.

Shukla, A., Singh, C. K., and Sharma, A. K. (2011). “Study of the properties of concrete bypartial replacement of ordinary Portland cement by rice husk ash.” International Journal of of Earth Sciences and Engineering, Vol. 4, No. 6, pp. 965–968.

Tangpagasit, J., Cheerarot, R., Jaturapitakkul, C., and Kiattikomol, K. (2005). “Packing effect and pozzolanic reaction of fly ash in mortar.” Cement and Concrete Research, Vol. 35 No. 6, pp. 1145–1151, DOI: 10.1016/j.cemconres.2004.09.030.

Tuan, N. V., Ye, G., Breugel, K. V., and Copuroglu, O. (2011). “Hydration and microstructure of ultra high performance concrete incorporating ricehuskash.” Cement and Concrete Research, Vol. 41, No. 11, pp. 1104–1111, DOI: 10.1016/j.cemconres.2011.06.009.

Venkatanarayanan, H. K. and Rangaraju, P. K. (2015). “Effect of grinding of low-carbon rice husk ash on the microstructure and performance properties of blended cement concrete.” Cement and Concrete Composites, Vol. 55, pp. 348–363, DOI: 10.1016/j.cemconcomp.2014.09.021.

Zain, M. F. M., Islam, M. N., Mahmud, F., and Jamil, M. (2011). “Production of rice husk ash for use in concrete as a supplementary cementitious material.” Construction and Building Materials, Vol. 25, No. 2, pp. 798–805, DOI: 10.1016/j.conbuildmat.2010.07.003.

Zhang, M. H., Lastra, R., and Malhotra, V. M. (1996). “Ricehusk ash paste and concrete: Some aspects of hydration and the microstructure of the interfacial zone between the aggregate and paste.” Cement and Concrete Research, Vol. 26, No. 6, pp. 963–977, DOI: 10.1016/0008-8846(96)00061-0.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, M.N.N., Jamil, M., Karim, M.R. et al. Filler effect of pozzolanic materials on the strength and microstructure development of mortar. KSCE J Civ Eng 21, 274–284 (2017). https://doi.org/10.1007/s12205-016-0737-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-016-0737-5