Abstract

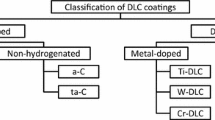

High-performance diamond films are highly demanded on tool surfaces for wire-drawing and mechanical sealing applications. Herein, this work aims at enhancing the tribological performance of chemical vapor deposition diamond films in water-lubricated conditions by utilizing non-hydrogenated and hydrogenated diamond-like carbon (DLC and DLC-H) top layers. The tribological properties of bilayer micro-crystalline diamond (MCD)/DLC, MCD/DLC-H, nano-crystalline diamond (NCD)/DLC and NCD/DLC-H films are evaluated, in terms of maximal and stable coefficients of friction (COFs), C-C bonds transformation, worn surface morphology and specific wear rates. The results show that DLC or DLC-H coated on diamond layer significantly suppresses the initial maximal COF peak and the wear of counterpart ball. Moreover, severe regular arranged sp2 C-C bonds transformation is detected on MCD film, in comparison to NCD; while inversely, the NCD/DLC bilayer exhibits severer C-C bonds transformation effect compared with the MCD/DLC. Furthermore, the DLC-H top layer shows a larger decreasing rate of maximal COFs and wear rates of counterpart balls, compared with the DLC coating, which is due to its superior self-lubricity. Among all the tested films, the NCD/DLC-H bilayer shows an optimized tribological performance.

摘要

高性能金刚石薄膜被广泛应用于拉拔和机械密封行业的工具表面涂层. 本研究旨在通过在金刚石薄膜表面沉积不含氢和含氢类金刚石碳(DLC和DLC-H)来增强化学气相沉积金刚石薄膜在水润滑条件下的摩擦学性能. 对于微米金刚石(MCD)与 纳米金刚石(NCD), 本文评估了MCD/DLC、 MCD/DLC-H、 NCD/DLC和NCD/DLC-H双层复合薄膜的摩擦性能, 包括最大和稳定摩擦系数(COF)、 C-C键转化、 磨损表面形态以及单位磨损率. 结果表明在金刚石薄膜表面沉积DLC或DLC-H涂层可显著降低复合薄膜的初始最大COF峰值和配对球的磨损. 同时, 与NCD相比, MCD薄膜表面存在更严重的规则排列的sp2 C-C键转化; 而相反, NCD/DLC双层薄膜显示出比MCD/DLC更严重的C-C键转化效应. 进一步发现, 作为顶层薄膜时, DLC-H由于其出色的自润滑性能, 较DLC薄膜显示出更大的COF和配对球的磨损率降幅. 在所有测试的薄膜中, NCD/DLC-H双层薄膜表现出最优化的摩擦学性能.

Similar content being viewed by others

References

SKORDARIS G, BOUZAKISK D, CHARALAMPOUS P, et al. Effect of structure and residual stresses of diamond coated cemented carbide tools on the film adhesion and developed wear mechanisms in milling [J]. CIRP Annals, 2016, 65(1): 101–104.

SHABANI M, CARRAPICHANO J M, OLIVEIRA F J, et al. Multilayered diamond mechanical seal rings under biodiesel lubrication and the full sealing conditions of pressurized water [J]. Wear, 2017, 384/385: 178–184.

SALGUEIREDO E, ABREU C S, AMARAL M, et al. Self-mated tribological systems based on multilayer micro/nanocrystalline CVD diamond coatings [J]. Wear, 2013, 303(1/2): 225–234.

LEI X L, SHEN B, CHEN S L, et al. Tribological behavior between micro- and nano-crystalline diamond films under dry sliding and water lubrication [J]. Tribology International, 2014, 69: 118–127.

YUAN Z W, JIN Z J, ZHANG Y J, et al. Chemical mechanical polishing slurries for chemically vapordeposited diamond films [J]. Journal of Manufacturing Science and Engineering, 2013, 135(4): 041006.

CASIRAGHI C, FERRARIAC, ROBERTSON J. Raman spectroscopy of hydrogenated amorphous carbons [J]. Physical Review B, 2005, 72(8): 085401.

ZENG Q F, YU F, DONG G N, et al. Mechanism analysis of improved DLC films friction behaviors with liquid sulfidation treatment [J]. Applied Surface Science, 2012, 259: 83–92.

SHEN B, CHEN S L, SUN F H. Investigation on the long-duration tribological performance of bilayered diamond/diamond-like carbon films [J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2014, 228(6): 628–641.

MIYOSHI K, WURLC, LANTERW C. Friction and wear of diamond like carbon on fine-grain diamond [J]. Tribology Letters, 1997, 3(2): 141–145.

WU D H, REN S M, PU J B, et al. A comparative study of tribological characteristics of hydrogenated DLC film sliding against ceramic mating materials for helium applications [J]. Applied Surface Science, 2018, 441: 884–894.

PODGURSKY V, BOGATOV A, YASHIN M, et al. A comparative study of the growth dynamics and tribological properties of nanocrystalline diamond films deposited on the (110) single crystal diamond and Si(100) substrates [J]. Diamond and Related Materials, 2019, 92: 159–167.

FELDER E, LEVRAU C, MANTEL M, et al. Identification of the work of plastic deformation and the friction shear stress in wire drawing [J]. Wear, 2012, 286/287: 27–34.

CHOBAUT N, DREZETJ M, MISCHLER S, et al. Miniaturized tube fixed plug drawing: Determination of the friction coefficients and drawing limit of 316 LVM stainless steel [J]. Journal of Materials Processing Technology, 2019, 263: 396–407.

XU Z Q, LEV L, LUKITSCH M, et al. Effects of surface pretreatments on the deposition of adherent diamond coatings on cemented tungsten carbide substrates [J]. Diamond and Related Materials, 2007, 16(3): 461–466.

BUIJNSTERSJ G, CAMERO M, VÁZQUEZ L, et al. Tribological study of hydrogenated amorphous carbon films with tailored microstructure and composition produced by bias-enhanced plasma chemical vapour deposition [J]. Diamond and Related Materials, 2010, 19(7/8/9): 1093–1102.

ABREU C S, OLIVEIRA F J, BELMONTE M, et al. CVD diamond coated silicon nitride self-mated systems: Tribological behaviour under high loads [J]. Tribology Letters, 2006, 21(2): 141–151.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 51705155), and the Tribology Science Fund of State Key Laboratory of Tribology (No. SKLTKF17B09)

Rights and permissions

About this article

Cite this article

Lei, X., Yan, Y., Zhang, H. et al. Enhanced Tribological Performance of Diamond Films by Utilizing DLC and DLC-H Top Layers. J. Shanghai Jiaotong Univ. (Sci.) 28, 665–675 (2023). https://doi.org/10.1007/s12204-021-2399-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-021-2399-9