Abstract

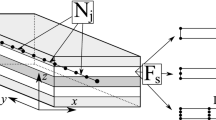

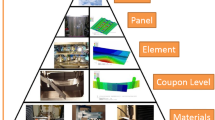

A representative volume element method and a novel mesomechanical-based polyline model are proposed to describe the misalignment of in-plane fibers induced by the insertion of stitch thread. A multi-scale mathematical model of in-plane elastic parameters for stitched composite laminate is established with ply-angle and stitch parameters as well as material parameters taken into account. Based on the fabrication of specimens and the verification of experimental platform, the superposition influences of stitch on structural anisotropy are revealed by the developed theoretical model. Results indicate that the stitch orientation can increase the structural anisotropy. The decreases of stitch pitch and spacing as well as the increase of thread diameter obviously reduce the elastic and shear moduli of laminates. Furthermore, the elastic and shear moduli as well as Poisson’s ratios show sinusoidal changes with a period of 90° as the ply-angle increases. The theoretical model not only analyzes the in-plane mechanical properties of stitched laminate with ply-angle, but also lays a foundation for the dynamic studies of stitched sandwich structures with ribs in the future.

摘要

提出了使用代表体积单元法和一种基于细观力学的折线模型来描述因插入缝线而导致的面内纤维偏转。考虑了铺层角度、缝合参数及材料参数,建立了缝合复合材料层合板面内等效弹性参数的多尺度数学模型。基于试件制备和试验验证,开发的理论模型揭示了缝合对结构各向异性的叠加效应。结果表明,缝合方向可以提高结构的各向异性。减小缝合针距与行距以及增大缝线直径,可以减小层合板的弹性模量和剪切模量。随着铺层角度的增大,弹性模量、剪切模量和泊松比均呈现出周期为90°的正弦变化。建立的理论模型不仅分析了带有铺层角度的缝合层合板的面内力学属性,还为以后加筋缝合夹芯结构的动力学研究奠定基础。

Similar content being viewed by others

Abbreviations

- a :

-

Length of distortion region of warp fibers for y-stitch direction, mm

- b :

-

Length of distortion region of warp fibers for x-stitch direction, mm

- D :

-

Diameter of stitch thread, mm

- E :

-

Row vector of elastic parameters

- E 1, E 2 :

-

Elastic moduli of plain weave lamina in 1- and 2-principle directions, respectively, GPa

- \({E_{{1_j}}},{E_{{2_j}}}\) :

-

Elastic moduli of unidirectional lamina in 1- and 2- principle directions, respectively, GPa

- \({E_{{x_j}}},{E_{{y_j}}}\) :

-

Elastic moduli of unidirectional lamina in x- and y-directions, respectively, GPa

- \({E_{{2_{\rm{s}}}}}\) :

-

Transverse elastic modulus of stitch thread, GPa

- G 12 :

-

Shear modulus of plain weave lamina in the 1–2 principle plane of material, GPa

- \({G_{{1_j}{2_j}}}\) :

-

Shear modulus of unidirectional lamina in the 1–2 principle plane of material, GPa

- \({G_{{x_j}{y_j}}}\) :

-

Shear modulus of unidirectional lamina in the x − y plane, GPa

- \({G_{{2_{\rm{s}}}{3_{\rm{s}}}}}\) :

-

Shear modulus in the plane perpendicular to the axial direction of stitch thread, GPa

- h :

-

Thickness of laminate, mm

- h (r) :

-

Thickness of the rth layer, mm

- k :

-

Corrugation influence coefficient

- L :

-

Stitch spacing, mm

- n 1,n 2 :

-

Contents of the warp and weft fibers in plain weave lamina per unit width, respectively N— Stitch pitch, mm

- p :

-

the number of layers

- S :

-

Flexibility matrix

- V :

-

Column vector of volume fractions of six regions

- V :

-

Volume fraction

- α :

-

Ply-angle

- γ :

-

Shear strain

- ε :

-

Normal strain

- ξ :

-

Coefficient

- θ :

-

Angle between the principle axis of material and the global coordinate axis

- µ :

-

Coefficient

- ν 21,ν 12 :

-

Major and minor Poisson’s ratios of plain weave lamina in principle coordinate system of material, respectively

- ν 1,ν 2 :

-

Major and minor Poisson ratios of unidirectional lamina in principle coordinate system, respectively

- \({\nu _{{y_j}{x_j}}},{\nu _{{x_j}{y_j}}}\) :

-

Major and minor Poisson’s ratios of unidirectional lamina in global coordinate system, respectively

- \({\nu _{{2_{\rm{s}}}{3_{\rm{s}}}}}\) :

-

Poisson’s ratio in the plane perpendicular to the axial direction of stitch thread

- σ :

-

Normal stress, GPa

- τ :

-

Shear stress, GPa

- m-warp:

-

Micro-strip of warp fiber

- m-weft:

-

Micro-strip of weft fiber

- r :

-

The rth layer

- (1):

-

Undistorted region

- (2):

-

Distorted region of warp fibers

- (3):

-

Distorted region of weft fibers

- (4):

-

Resin-rich pocket

- (5):

-

Stitch thread region

- (6):

-

Distorted region of both warp and weft fibers

- f:

-

Fiber

- ip:

-

In-plane

- j :

-

Unidirectional lamina made by warp (j = 1) or weft (j = 2) fibers

- m:

-

Matrix

References

GNABA I, LEGRAND X, WANG P, et al. Through-the-thickness reinforcement for composite structures: A review [J]. Journal of Industrial Textiles, 2019, 49(1): 71–96.

DAU F, DANO M L, DUPLESSIS-KERGOMARD Y. Experimental investigations and variability considerations on 3D interlock textile composites used in low velocity soft impact loading [J]. Composite Structures, 2016, 153: 369–379.

AHN H, YU W R. Mechanical analysis of 3D braided and woven composites using fiber-based continuum analysis [J]. Composite Structures, 2017, 160: 1105–1118.

CASTANEDA N, WISNER B, CUADRA J, et al. Investigation of the Z-binder role in progressive damage of 3D woven composites [J]. Composites Part A: Applied Science and Manufacturing, 2017, 98: 76–89.

SELTZER R, GONZÁLEZ C, MUÑOZ R, et al. X-ray microtomography analysis of the damage micromechanisms in 3D woven composites under low-velocity impact [J]. Composites Part A: Applied Science and Manufacturing, 2013, 45: 49–60.

CHEN K, LIU L, WANG H. Analysis of through-the-thickness stress distribution in thick laminate multi-bolt joints using global-local method [J]. Journal of Shanghai Jiao Tong University (Science), 2013, 18(3): 326–333.

PAPPAS G, JONCAS S, MICHAUD V, et al. The influence of through-thickness reinforcement geometry and pattern on delamination of fiber-reinforced composites: Part I — Experimental results [J]. Composite Structures, 2018, 184: 924–934.

GÖKTAŞ D, KENNON W R, POTLURI P. Improvement of mode I interlaminar fracture toughness of stitched glass/epoxy composites [J]. Applied Composite Materials, 2017, 24: 351–375.

DRANSFIELD K A, JAIN L K, MAI Y W. On the effects of stitching in CFRPs—I. mode I delamination toughness [J]. Composites Science and Technology, 1998, 58(6): 815–827.

XUAN J, LI D, JIANG L. Fabrication, properties and failure of 3D stitched carbon/epoxy composites with no stitching fibers damage [J]. Composite Structures, 2019, 220: 602–607.

RAVANDI M, TEO W S, TRAN L Q N, et al. The effects of through-the-thickness stitching on the Mode I interlaminar fracture toughness of flax/epoxy composite laminates [J]. Materials and Design, 2016, 109: 659–669.

YUDHANTO A, WATANABE N, IWAHORI Y, et al. Effect of stitch density on tensile properties and damage mechanisms of stitched carbon/epoxy composites [J]. Composites Part B: Engineering, 2013, 46: 151–165.

KAYA G, SOUTIS C, POTLURI P. Tensile properties of a novel graphene pattern stitched carbon/epoxy 3D composite [J]//IOP Conference Series: Materials Science and Engineering, 2018, 460: 012015.

RONG M Z, ZHANG M Q, LIU Y, et al. Effect of stitching on in-plane and interlaminar properties of sisal/epoxy laminates [J]. Journal of Composite Materials, 2002, 36(12): 1505–1526.

WU E, WANG J. Behavior of stitched laminates under in-plane tensile and transverse impact loading [J]. Journal of Composite Materials, 1995, 29(17): 2254–2279.

YUDHANTO A, LUBINEAU G, VENTURA I A, et al. Damage characteristics in 3D stitched composites with various stitch parameters under in-plane tension [J]. Composites Part A: Applied Science and Manufacturing, 2015, 71: 17–31.

WANG P, LEI Y, YUE Z. Experimental and numerical evaluation of the flexural properties of stitched foam core sandwich structure [J]. Composite Structures, 2013, 100: 243–248.

AI S, MAO Y, PEI Y, et al. Effect of stitching angle on mechanical properties of stitched sandwich panels [J]. Materials and Design, 2013, 50: 817–824.

VALLONS K, ADOLPHS G, LUCAS P, et al. The influence of the stitching pattern on the internal geometry, quasi-static and fatigue mechanical properties of glass fibre non-crimp fabric composites [J]. Composites Part A: Applied Science and Manufacturing, 2014, 56: 272–279.

JOSHI P, KONDO A, WATANABE N. Progressive failure analysis of carbon-fibre/epoxy composites laminates to study the effect of stitch densities under in-plane tensile loading [J]. Plastics, Rubber and Composites, 2017, 46(4): 147–154.

BARILE C, CASAVOLA C, PAPPALETTERE C. The influence of stitching and unconventional fibres orientation on the tensile properties of CFRP laminates [J]. Composites Part B: Engineering, 2017, 110: 248–254.

HOSUR M V, KARIM M R, JEELANI S. Experimental investigations on the response of stitched/unstitched woven S2-glass/SC15 epoxy composites under single and repeated low velocity impact loading [J]. Composite Structures, 2003, 61(1/2): 89–102.

MOURITZ A P, COX B N. A mechanistic interpretation of the comparative in-plane mechanical properties of 3D woven, stitched and pinned composites [J]. Composites Part A: Applied Science and Manufacturing, 2010, 41(6): 709–728.

ZHANG J, WEI Y. A predictive approach to the in-plane mechanical properties of stitched composite laminates [J]. Acta Mechanica Solida Sinica, 2007, 20: 130–140.

YUDHANTO A, WATANABE N, IWAHORI Y, et al. The effects of stitch orientation on the tensile and open hole tension properties of carbon/epoxy plain weave laminates [J]. Materials and Design, 2012, 35: 563–571.

General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354-2014 [S]. Beijing: Standards Press of China, 2014 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

the National Natural Science Foundation of China (No. 52075280), and the Natural Science Foundation of Shandong Province (No. ZR2019MEE088)

Rights and permissions

About this article

Cite this article

Yuan, L., Liang, S. & Yan, S. In-Plane Elastic Properties of Stitched Plain Weave Composite Laminate. J. Shanghai Jiaotong Univ. (Sci.) 28, 220–232 (2023). https://doi.org/10.1007/s12204-021-2375-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-021-2375-4

Key words

- stitched composite laminate

- in-plane mechanical property

- superposition influence

- ply-angle

- structural anisotropy