Abstract

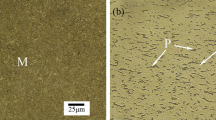

The hot-stamped steel with ultrahigh strength is a promising material for the fabrication of automotive components. However, the coating on the sheet surface leads to a softening problem in the welded joint. Instead of the costly coating removal process, heat treatment is an economical and effective method for the diffusion process, which can decrease the Al concentration in the coating. In this study, a preheating treatment was carried out on Al-Si-coated 22MnB5 hot-stamped steels for the homogeneity of Al, followed by laser welding and hot stamping. The effects of the preheating on the microstructure and mechanical properties of the laser-welded joints were investigated. With the preheating treatment, the Al-Si coating transformed into an Fe-Al intermetallic compound and the difference in Al content between the coating and substrate was reduced. The Al content in the weld of the specimen with the preheating treatment was reduced, compared with that without the preheating treatment. The amount of δ-ferrite in the weld after laser welding was reduced largely. The distribution of long-bland-like segregation was changed to a fine and uniform distribution. With the preheating treatment, the tensile strength of the welded joint was significantly improved and comparable to that of the decoated joint. In conclusion, the preheating treatment before the welding is an effective method to suppress the formation of δ-ferrite and improve the mechanical properties of the welded joint.

Similar content being viewed by others

References

KARBASIAN H, TEKKAYA A E. A review on hot stamping [J]. Journal of Materials Processing Technology, 2010, 210(15): 2103–2118.

TAYLOR T, CLOUGH A. Critical review of automotive hot-stamped sheet steel from an industrial perspective [J]. Materials Science and Technology, 2018, 34(7): 809–861.

FAN D W, DE COOMAN B C. State-of-the-knowledge on coating systems for hot stamped parts [J]. Steel Research International, 2012, 83(5): 412–433.

LIN W H, LI F, WU D S, et al. Effect of Al-Si coating on weld microstructure and properties of 22MnB5 steel joints for hot stamping [J]. Journal of Materials Engineering and Performance, 2018, 27(4): 1825–1836.

SAHA D C, BIRO E, GERLICH A P, et al. Fusion zone microstructure evolution of fiber laser welded press-hardened steels [J]. Scripta Materialia, 2016, 121: 18–22.

VIERSTRAETE R, EHLING W, PINARD F, et al. Laser ablation for hardening laser welded steel blanks [J]. Industrial Laser Solutions for Manufacturing, 2010, 25: 6–11.

FLEHMIG T, GORSCHLÜTER J, WISCHMANN S. Method and device for mechanically removing coatings from coated blanks using a press and scraping knife: US9682489 [P]. 2017-06-20 [2020-09-10].

LIN W H, LI F, HUA X M, et al. Effect of filler wire on laser welded blanks of Al-Si-coated 22MnB5 steel [J]. Journal of Materials Processing Technology, 2018, 259: 195–205.

SUN Q, DI H S, WANG X N, et al. Suppression of δ-ferrite formation on Al-Si coated press-hardened steel during laser welding [J]. Materials Letters, 2019, 245: 106–109.

KANG M, KIM C, BAE S M. Laser tailor-welded blanks for hot-press-forming steel with arc pretreatment [J]. International Journal of Automotive Technology, 2015, 16(2): 279–283.

FAN D W, KIM H S, OH J K, et al. Coating degradation in hot press forming [J]. ISIJ International, 2010, 50(4): 561–568.

MAITRA T, GUPTA S P. Intermetallic compound formation in Fe-Al-Si ternary system: Part II [J]. Materials Characterization, 2002, 49(4): 293–311.

GUI Z X, LIANG W K, ZHANG Y S. Enhancing ductility of the Al-Si coating on hot stamping steel by controlling the Fe-Al phase transformation during austenitization [J]. Science China Technological Sciences, 2014, 57(9): 1785–1793.

SAHA D C, BIRO E, GERLICH A P, et al. Fiber laser welding of Al-Si-coated press-hardened steel [J]. Welding Journal, 2016, 95(5): 147–156.

KIM C, KANG M J, PARK Y D. Laser welding of Al-Si coated hot stamping steel [J]. Procedia Engineering, 2011, 10: 2226–2231.

MOON J H, SEO P K, KANG C G. A study on mechanical properties of laser-welded blank of a boron sheet steel by laser ablation variable of Al-Si coating layer [J]. International Journal of Precision Engineering and Manufacturing, 2013, 14(2): 283–288.

CHEN X G, LI F, LIN W H, et al. Effect of boron steel coating on microstructure and property of laser tailor-welded blanks after hot stamping [J]. Chinese Journal of Lasers, 2017, 44(4): 115–124 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 51705318), and the Project of LNG Shipbuilding from the Ministry of Industry and Information Technology of China

Rights and permissions

About this article

Cite this article

Wang, Q., Lin, W., Li, F. et al. Influence of Thermal Modification on Al-Si Coating of Hot-Stamped 22MnB5 Steel: Microstructure, Phase Transformation, and Mechanical Properties. J. Shanghai Jiaotong Univ. (Sci.) 26, 747–756 (2021). https://doi.org/10.1007/s12204-021-2267-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-021-2267-7