Abstract

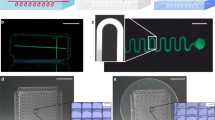

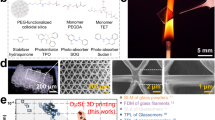

A new hybrid method, which combines improved glass-blown technology with wet etching, is reported to fabricate micro wine-glass resonators with high-quality fused silica. The optimum placement is compared to achieve the resonators with good shell shape. The typical shell diameter is about 4mm and its thickness covers from dozens to hundreds of micrometers. The etching rates in corrosion solutions with different ratios and at different thicknesses of hemispherical shells are studied. We also conclude how to precisely control the thickness. The corrosion solutions with different ratios of HF solution to NH4F solution make the spherical shells rougher in different degrees. The best roughness is 0.581 nm in the 1: 8 ratio corrosion solution while the original roughness is 0.537 nm. This fact shows that the resonator remains atomically smooth surface. Based on the glassblowing spherical fused silica structure, the thickness of the resonator is effectively controlled by buffered oxide etch (BOE) technology according to the measured etching rate. The measured resonant frequency of the hemispherical shell at ambient pressure and room temperature is 1.75 kHz of rocking mode which is close to the simulated frequency. Using such a low-cost hybrid approach, we can fabricate high-quality microscale resonators in batch.

Similar content being viewed by others

References

EKLUND E J, SHKEL A M. Glass blowing on a wafer level [J]. Journal of Microelectromechanical Systems, 2007, 16(2): 232–239.

SHAO P, TAVASSOLI V, MAYBERRY C L, et al. A 3D-HARPSS polysilicon micro-hemispherical shell resonating gyroscope: Design, fabrication, and characterization [J]. IEEE Sensors Journal, 2015, 15(9): 4974–4985.

KANIK M, BORDEENITHIKASEM P, SCHROERS J, et al. Microscale three-dimensional hemispherical shell resonators fabricated from metallic glass [C]//International Symposium on Inertial Sensors and Systems (ISISS). [s.l.]: IEEE, 2014: 1–4.

PAI P, CHOWDHURY F K, MASTRANGELO C H, et al. MEMS-based hemispherical resonator gyroscopes [J]. IEEE Sensors, 2012. Doi: 10.1109/ICSENS.2012.6411346 (published online).

HEIDARI A, CHAN M L, YANG H A, et al. Micromachined polycrystalline diamond hemispherical shell resonators [C]//The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers & Eurosensors XXVII). Barcelona: IEEE, 2013: 2415–2418.

SENKAL D, AHAMED M J, ASKARI S, et al. 1 million Q-factor demonstrated on micro-glassblown fused silica wineglass resonators with out-of-plane electrostatic transduction [C]//Solid-State Sensors, Actuators and Microsystems Workshop. South Carolina: IEEE, 2014: 68–71.

XIE Y, HSIEH H C, PAI P, et al. Precision curved micro hemispherical resonator shells fabricated by poached-egg micro-molding [J]. IEEE Sensors, 2012. Doi: 10.1109/ICSENS. 2012.6411085 (published online).

CHO J, YAN J, GREGORY J A, et al. High-Q fused silica birdbath and hemispherical 3-D resonators made by blow torch molding [C]//IEEE 26th International Conference on Micro Electro Mechanical Systems (MEMS). [s.l.]: IEEE, 2013: 177–180.

AHAMED M J, SENKAL D, TRUSOV A A, et al. Deep NLD plasma etching of fused silica and borosilicate glass [J]. IEEE Sensors, 2013. Doi: 10.1109/ICSENS. 2013.6688574 (published online).

GUO D Z. Effect of electrode surface roughness on MEMS parallel plate capacitor [C]//Proceedings of 5th Annual Conference of China Society of Inertial Technology. Beijing: Chinese Society of inertial Technology, 2003: 211–215 (in Chinese).

ALBINA A, TABERNA P L, CAMBRONNE J P, et al. Impact of the surface roughness on the electrical capacitance [J]. Microelectronics Journal, 2006, 37(8): 752–758.

PECZALSKI A, WU Z Z, TABRIZIAN R, et al. Investigation into the quality factor of piezoelectric-onsilica micromachined resonators [J]. Journal of Microelectromechanical Systems, 2015, 24(6): 1695–1702.

FIREBAUGH S L, CHARLES H K, EDWARDS R L, et al. Optical deflection measurement for characterization of microelectromechanical systems (MEMS) [J]. IEEE Transactions on Instrumentation and Measurement, 2004, 53(4): 1047–1051.

KNAUSS W G, CHASIOTIS I, HUANG Y. Mechanical measurements at the micron and nanometer scales [J]. Mechanics of Materials, 2003, 35(3): 217–231.

Acknowledgement

The authors would like to thank the cleanroom staff at Center for Advanced Electronic Materials and Devices (AEMD) and Engineering Mechanics Experiment Center.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 61574093), the Program for New Century Excellent Talents in University of Ministry of Education of China (No. NCET-10-0583), the Science Fund Program (No. 2013ZC57003), the Pre-research Fund (No. 9140A14010511JW0304) and the Fund of National Key Laboratory of Science and Technology on Nano/Micro Fabrication, Shanghai Jiao Tong University (No. 9140C790405110C7904)

Rights and permissions

About this article

Cite this article

Xing, Y., Zhang, W., Tang, J. et al. Hybrid process of fabricating high-quality micro wine-glass fused silica resonators. J. Shanghai Jiaotong Univ. (Sci.) 22, 274–279 (2017). https://doi.org/10.1007/s12204-017-1832-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-017-1832-6