Abstract

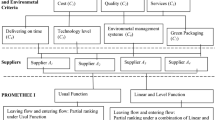

An effective maintenance schedule can largely improve productivity and reduce maintenance costs for enterprises. Many factors, such as resource, production, cost and crew, should be considered when we make maintenance plans. However, it is difficult to meet all requests of the production targets in practical engineering. The multiple attribute decision making for equipment maintenance is proposed in this paper, and the multiple objectives decision making method is utilized to solve the problem in the maintenance process. In the particular environment and resources, a case is studied to illustrate the model and methods. The model gives the optimal maintenance plan with the analytic hierarchy process method in accordance with the particular criteria. It has been proved that this model and decision methods are scientific and operable.

Similar content being viewed by others

References

FIGUEIRA J, GRECO S, EHRGOTTM. Multiple criteria decision analysis: State of the art surveys [M]. New York, USA: Springer, 2005.

GODOY D R, PASCUAL R, KNIGHTS P. A decisionmaking framework to integrate maintenance contract conditions with critical spares management [J]. Reliability Engineering and System Safety, 2014, 131(10): 102–108.

ASSAF S A, HADIDI L A, HASSANAIN M A, et al. Performance evaluation and benchmarking for maintenance decision making units at petrochemical corporation using a DEA model [J]. International Journal of Advanced Manufacturing Technology, 2015, 76(9): 1957–1967.

XIA T, JIN X, XI L, et al. Operating load based realtime rolling grey forecasting for machine health prognosis in dynamic maintenance schedule [J]. Journal of Intelligent Manufacturing, 2015, 26(2): 269–280.

WANG H, LIN D, QIU J, et al. Research on multiobjective group decision-making in conditionbased maintenance for transmission and transformation equipment based on D-S evidence theory [J]. IEEE Transactions on Smart Grid, 2015, 6(2): 1035–1045.

FLETCHER J D, JOHNSTON R. Effectiveness and cost benefits of computer-based decision aids for equipment maintenance [J]. Computers in Human Behavior, 2002, 18(6): 717–728.

WANG J. Application of multi-objective and multiattribute decision-making methods in asphalt pavement sorting maintenance [C]// Proceedings of the 2th International Conference on Intelligent Computation Technology and Automation. Zhangjiajie, China: IEEE, 2009: 365–367.

ZHANG H B, ZHENG Z Q, LI Z N, et al. An analytic hierarchy process based method for identifying coherent generator groups [C]// Proceedings of the International Conference on Electricity Distribution. Shenzhen, China: IEEE, 2014: 490–494.

DEKKER R, SCARF P A. On the impact of optimization models in maintenance decision making: The state of the art [J]. Reliability Engineering and System Safety, 1998, 60(2): 111–119.

HORENBEEK A V, PINTELON L. A prognostic maintenance policy-effect on component lifetimes [C]// Proceedings of the 2013 Annual Reliability and Maintainability Symposium. Orlando, USA: IEEE, 2013: 1–6.

CAI Z Q, SUN S D, SI S B, et al. Integrated importance based maintenance decision making [C]// Proceedings of the 2012 Annual Reliability and Maintainability Symposium. Reno, USA: IEEE, 2012: 495–501.

WANG Y P, PHAM H. A multi-objective optimization of imperfect preventive maintenance policy for dependent competing risk systems with hidden failure [J]. IEEE Transactions on Reliability, 2011, 60(4): 770–781.

DONG X F, GU Y J, YANG K. Study on intelligent maintenance decision support system using for power plant equipment [C]// Proceedings of IEEE International Conference on Automation and Logistics. Qingdao, China: IEEE, 2008: 96–100.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 71471147), the Natural Science Research Project of Shaanxi Province (No. 2015JQ7273) and the Seed Foundation of Innovation and Creation for Graduate Students in Northwestern Polytechnical University (No. Z2016087)

Rights and permissions

About this article

Cite this article

Cai, Z., Li, Y., Zhang, S. et al. Maintenance decision making model with multiple attribute optimization. J. Shanghai Jiaotong Univ. (Sci.) 21, 499–503 (2016). https://doi.org/10.1007/s12204-016-1754-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-016-1754-8