Abstract

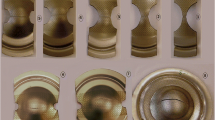

In metal forming processes such as sheet blanking, severe plastic deformation localizes in a narrow shear band near blanking clearance, and ductile fracture occurs at the final stage. Because the combinations of large nonlinear strain localization, displacement discontinuity and ductile fracture brought obstacles to numerical simulation, a ductile fracture initiation criterion model and an elasto-plastic finite element method (FEM) were presented to simulate localized severe plastic deformation. Initiation and propagation of cracks were treated by deletion-and-replacement approach. The distributions and developing trends of effective strain and damage were predicted, the influence of blanking clearance on fracture was discussed, and an experiment was performed to explore the forming mechanism.

Similar content being viewed by others

References

Brokken D, Brekelmans W A M, Baaijens F P T. Predicting the shape of blanked products: A finite element approach [J]. Journal of Materials Processing Technology, 2000, 103: 51–56.

Huespe A E, Needleman A, Oliver J. A finite thickness band method for ductile fracture analysis [J]. International Journal of Plasticity, 2009, 25: 2349–2365.

Lemialea V, Chambert J, Picart P. Description of numerical techniques with the aim of predicting the sheet metal blanking process by FEM simulation [J]. Journal of Materials Processing Technology, 2009, 209: 2723–2734.

Ortiz M, Leroy Y, Needleman A. A finite element method for localized failure analysis [J]. Computer Methods in Applied Mechanics and Engineering, 1987, 61(2): 189–214.

Yu S, Xie X L, Zhang J, et al. Ductile fracture modelling of initiation and propagation in sheet-metal blanking processes [J]. Journal of Materials Processing Technology, 2007, 187–188: 169–172.

Lewis R W, Khoei A R. Numerical analysis of strain localization in metal powder-forming processes [J]. International Journal for Numerical Methods in Engineering, 2001, 52: 489–501.

Chen Z H, Tang C Y, Lee T C, et al. Numerical simulation of fine-blanking process using a mixed finite element method [J]. International Journal of Mechanical Sciences, 2002, 44: 1309–1333.

Mcclintock F A. A criterion of ductile fracture by the growth of holes [J]. Journal of Applied Mechanics, 1968, 35: 363–371.

Rice J R, Tracey D M. On the ductile enlargement of voids in triaxial stress fields [J]. Journal of Mechanics and Physics of Solids, 1969, 17: 201–217.

Xue L, Wierzbicki T. Ductile fracture initiation and propagation modeling using damage plasticity theory [J]. Engineering Fracture Mechanics, 2008, 75: 3276–3293.

Brozzo P, Deluca B, Rendina R. A new method for the prediction of formability limits in metal sheets, sheet metal forming and formability [C]//Proceedings of the Seventh Biennial Conference of the International Deep Drawing Research Group. Amsterdam: [s.n.], 1972: 9–13.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 51175310)

Rights and permissions

About this article

Cite this article

Yu, S., Zhao, J. Investigation on blanking of thick sheet metal using the ductile fracture initiation and propagation criterion. J. Shanghai Jiaotong Univ. (Sci.) 17, 531–536 (2012). https://doi.org/10.1007/s12204-012-1320-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-012-1320-y