Abstract

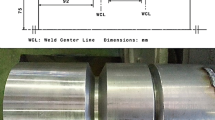

The numerical thermal mechanical simulation of radial forging process of steel H13 stepped shaft with GFM (Gesellschaft fur Fertigungstechnik und Maschinenbau) forging machine was carried out by three-dimensional finite element code DEFORM 3D. According to the effective plastic strain, the mean stress and the mean plastic strain distribution of the radial forging, the forging penetration efficiency (FPE) was studied throughout each operation. The results show that the effective plastic strain in the center of the forging is always greater than zero for the desirable larger axial drawing velocity. The mean stress in the center of the workpiece is proposed to describe hydrostatic pressure in this paper. There is compressive strain layer beneath the surface of the workpiece to be found, while there is tensile strain core in the center of the workpiece. These results could be a valuable reference for designing the similar forging operations.

Similar content being viewed by others

References

Altan T, Oh S, Gegel H L. Metal forming fundamental and applications [M]. Metals Park, OH: American Society for Metals, 1983.

Semiatin S L. Forming and forging [M]. Metals Park, OH: ASM International, 1988.

Ghaei A, Movahhedy M R, Karimi T A. Study of the effects of die geometry on deformation in the radial forging process [J]. Journal of Materials Processing Technology, 2005, 170(1–2): 156–163.

Ghaei A, Karimi T A, Movahhedy M R. A new upper bound solution for analysis of the radial forging process [J]. International Journal of Mechanical Sciences, 2006, 48(11): 1264–1272.

Ghaei A, Movahhedy M R. Die design for the radial forging process using 3D FEM [J]. Journal of Materials Processing Technology, 2007, 182(1–2): 534–539.

Sanjari M, Karimi T A, Ghaei A. Prediction of neutral plane and effects of the process parameters in radial forging using an upper bound solution [J]. Journal of Materials Processing Technology, 2007, 186(1–3): 147–153.

Ghaei A, Movahhedy M R, Karimi T A. Finite element modelling simulation of radial forging of tubes without mandrel [J]. Materials and Design, 2008, 29(4): 867–872.

Dyja H, Banaszek G, Mróz S, et al. Modelling of shape anvils in free hot forging of long products [J]. Journal of Materials Processing Technology, 2004, 157–158: 131–137.

Sahoo A K, Tiwari M K, Mileham A R. Six sigma based approach to optimize radial forging operation variables [J]. Journal of Materials Processing Technology, 2008, 202(1–3): 125–136.

Bapari A, Najafizadeh A, Moazeny M, et al. Simulation of radial forging conditions by third hits hot compression tests [J]. Materials Science and Engineering A, 2008, 491(1–2): 258–265.

Yang Shi-yong, Su Chang-qing, Wang Wei-hua. An experimental study of radial forging [J]. Equipment Environmental Engineering, 1987(3): 23–26 (in Chinese).

Yang S Y. Research into the GFM forging next term process [J]. Journal of Materials Processing Technology, 1991, 28(3): 307–319.

Wang Zhen-fan, Hu Zong-shi. Stream function method for final forging process analysis in radial forging [J], Journal of Northeastern University, 1994, 15(1): 35–39 (in Chinese).

Hu Zong-shi. The forging penetration efficiency of forging titanium alloy rod [J], Titanium Industry Progress, 2000(5): 15–18 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Xd., Liu, Xr. & Xing, Jb. Forging penetration efficiency of steel H13 stepped shaft radial forging with GFM forging machine. J. Shanghai Jiaotong Univ. (Sci.) 17, 315–318 (2012). https://doi.org/10.1007/s12204-012-1276-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-012-1276-y