Abstract

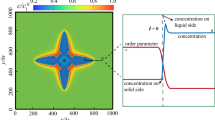

A phase-field model (PFM) coupling with phase field, flow field and diffuse equation is presented for simulating isothermal dendrite growth of a nickel-copper alloy under a forced flow. Based on the finite difference method with uniform grid, the C programming code is implemented to complete the phase-field simulations. The simulation results indicate that the interfacial morphology, the symmetry of dendrite formation, the tip growth velocity and the concentration distribution are strongly influenced by the fluid flow.

Similar content being viewed by others

References

Grier D, Ben-Jacob E, Clarke R, et al. Morphology and microstructure in electrochemical deposition of zinc [J]. Physical Review Letters, 1986, 56(12): 1264–1267.

Martin O, Goldenfeld N. Origin of sidebranching in dendritic growth [J]. Physical Review A, 1987, 35(3): 1382–1390.

Lee Y W, Gill W N, Ananth R. Forced convection heat transfer during dendritic crystal growth: Local solutions of Navier-Stokes equations [J]. Chemical Engineering Communications, 1992, 116(1): 193–200.

Hill S C, Alexander J I D. Modified diffusionlimited aggregation simulation of electrodeposition in two dimensions [J]. Physical Review E, 1997, 56(4): 4317–4327.

Tönhardt R, Amberg G. Phase-field simulation of dendritic growth in a shear flow [J]. Journal of Crystal Growth, 1998, 194(3–4): 406–425.

Tönhardt R, Amberg G. Dendritic growth of randomly oriented nuclei in a shear flow [J]. Journal of Crystal Growth, 2000, 213(1–2): 161–187.

Tong X, Beckermann C, Karma A. Velocity and shape selection of dentritic crystals in a forced flow [J]. Physical Review E, 2000, 61(1): 49–53.

Tong X, Beckermann C, Karma A. Phase-filed simulations of dendritic crystal growth in forced flow [J]. Physical Review E, 2001, 63(6): 1–16.

Lan C W, Shih C J. Phase field simulation of nonisothermal free dendritic growth of a binary alloy in a forced flow [J]. Journal of Crystal Growth, 2004, 264(7–8): 472–482.

Lan C W, Shih C J. Efficient phase field simulation of a binary dendritic growth in a forced flow [J]. Physical Review E, 2004, 69(3): 1–10.

Warren J A, Boettinger W J. Prediction of dendritic growth and microsegregation patterns in a binary alloy using the phase-field method [J]. Acta Metallurgica et Materialia, 1995, 43(2): 689–703.

Xiao Rong-zhen, Wang Zhi-ping, Zhu Chang-sheng, et al. Influence of anisotropy on dendritic growth in binary alloy with phase-field simulation [J]. ISIJ International, 2009, 49(8): 1156–1160.

Beckermann C, Diepers H-J, Steinbach I, et al. Modeling melt convection in phase-field simulations of solidification [J]. Journal of Computational Physics, 1999, 154(2): 468–496.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (Nos. 10964004 and 50804019), and the Natural Science Foundation of Gansu Province (No. 1014RJZA003)

Rights and permissions

About this article

Cite this article

Xiao, Rz., Wang, Zp., Zhu, Cs. et al. Phase-field modeling of free dendritic growth in binary alloy under forced flow. J. Shanghai Jiaotong Univ. (Sci.) 16, 356–359 (2011). https://doi.org/10.1007/s12204-011-1160-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-011-1160-1