Abstract

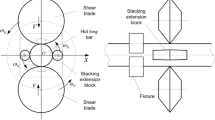

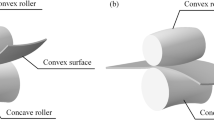

In a coil box between the roughing and finishing stands on a hot strip mill, a problem has been encountered that the entry region of the plate touches the bending rolls and deforms. As a result, the defective coil occurs. The condition of plate bending, which forms a new deformation feature in coiling, is analyzed. In this paper, the authors focus on the research of the effects of coiling parameters, such as the thickness of plate, roll speed and feeding speed of plate in coil box, and on specific plate bending. A finite element method is developed to simulate this coiling process. Based on numerical simulation, the effects of the coiling parameters on the mechanics and deformation of the bending plate are obtained. Numerical simulation tests have verified the validity of the developed model.

Similar content being viewed by others

References

Murray C, Kenney M. The Steltech coil box: Evolution of a winning technology [C]//Proc International Hot Rolling Conference. Beijing: Hatch Steltech Ltd., 2001: 7–13.

Averink H. Coil eye formation [C]//The 4th International Coil Box Symposium. Ontario: Hatch Steltech Ltd., 1995: 21–26.

Mckenney C M. Scope of project to device centric algorithms relating to coilbox bending roll gap [C]// The 5th International Coil Box Symposium. Ontario: Hatch Steltech Ltd., 1998: 92–96.

[4]Yu Xiang-long, YANG Quan, He An-ri, et al. Analysis of stress in coil eye formation on hot coilbox [J]. Metallurgical Equipment, 2007, 166(6): 33–39 (in Chinese).

Yu Xiang-long, Yang Quan, Jiang Zheng-yi. Analysis of plate bending in coilbox by finite element method [J]. Key Engineering Materials, 2010, 443(1): 146–151.

[6]Mori K I, Oketani N. Prediction of coiling conditions of plate in coilbox by controlled FEM simulation [J]. International Journal Machine Tools and Manufacture, 1999, 39(3): 403–413.

Zhou Ji-huan. Metal plastic deformation resistance [M]. Beijing: Mechanical Industry Press, 1989 (in Chinese).

Jiang Zheng-yi, Tieu A K, Lu Cheng. A FEM modelling of the elastic deformation zones in flat rolling [J]. Journal of Materials Processing Technology, 2004, 146(2): 167–174.

Jiang Zheng-yi, Tieu A K. Elastic-plastic finite element method simulation of thin strip with tension in cold rolling [J]. Journal of Materials Processing Technology, 2002, 130–131(1): 511–515.

Jiang Zheng-yi, Tieu A K, Tang Jie, et al. Characterisation of thin oxide scale and its surface roughness in hot metal rolling [J]. Materials Science and Engineering A: Structural Materials Properties Microstructure and Processing, 2006, 435–436(1): 434–438.

Livermore Software Technology Corporation. LS-DYNA keyword user’s manual [M]. Livermore: Livermore Software Technology Corporation, 2003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Xl., Yang, Q., Jiang, Zy. et al. Study on bending conditions of plate in coil box. J. Shanghai Jiaotong Univ. (Sci.) 16, 324–328 (2011). https://doi.org/10.1007/s12204-011-1153-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-011-1153-0