Abstract

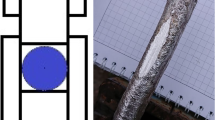

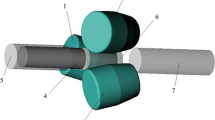

This paper discusses the application of several techniques involved in the development of the 3D finite element (FE) models of rod and wire continuous rolling process. The FE models are implemented into the FE-program MSC.Marc and used to investigate the thermal and mechanical behavior of billet during the rolling process. All nonlinear equations included in the models are solved by the static and dynamic procedures, respectively. Data transfer technique is proposed to keep the continuity of simulation results. And the computational time of static procedure is significantly reduced by using a rigid pushing body. In all models, the constant time step method and the auto time step method are respectively used to define time step for the solution of equations. Simulation results of the models with different time step methods are compared. And comparison between calculated values and measured ones of the temperature at the surface of billet shows the validity of the FE models.

Similar content being viewed by others

References

Glowacki M. The mathematical modelling of thermomechanical processing of steel during multi-pass shape rolling [J]. Journal of Materials Processing Technology, 2005, 168(2): 336–343.

Komori K. Simulation of deformation and temperature in caliber rolling: Effect of finite-element mesh in cross-section [J]. Journal of Materials Processing Technology, 2003, 143–144: 367–372.

Lee HW, Kwon H C, Im Y T, et al. Numerical investigation of austenite grain size distribution in squarediamond pass hot bar rolling [J]. Journal of Materials Processing Technology, 2007, 191(1–3): 114–118.

Li Xue-tong, Wang Min-ting, Du Feng-shan. Coupling thermomechanical and microstructural FE analysis in plate rolling process [J]. Journal of Iron and Steel Research, International, 2008, 15(4): 42–50.

Yuan Si-yu, Zhang Li-wen, Liao Shu-lun, et al. 3D FE analysis of thermal behavior of billet in rod and wire hot continuous rolling [J]. Journal of Iron and Steel Research, International, 2007, 14(1): 29–32.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Lw., Yue, Cx., Yuan, Sy. et al. Finite element simulation of rod and wire continuous rolling. J. Shanghai Jiaotong Univ. (Sci.) 16, 195–198 (2011). https://doi.org/10.1007/s12204-011-1120-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-011-1120-9