Abstract

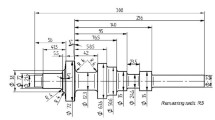

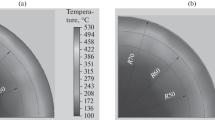

The paper presents the results of a thermo-mechanical analysis of the rolling two stepped shafts. One of the shafts has a toothed step with skew teeth, while the other has a worm winding in the shape of a trapezoidal screw. The shape of the rolling tools resembles that of the tools used in the Roto-Flo rolling method; yet unlike in Roto-Flo, the shafts are hot-rolled and no centres are used to stabilize the position of the workpiece during the forming process. For the calculations made with use of the DEFORM-3D process simulation system it has been assumed that the rolled shafts are made from 2618 aluminium alloy. As a result of the calculations made, it has been found that the toothed stepped shafts can be formed in one pass by means of the cross rolling process. Additionally, the temperature and strain distribution in the rolled product have been determined as well as some data concerning the forces which are necessary for the rolling process have been obtained.

Similar content being viewed by others

References

Lange K. Handbook of metal forming [M]. New York: Mc Graw Hill Book Company, 1985.

Songa J H, Im Y T. Process design for closed-die forging of bevel gear by finite element analyses [J]. Journal of Materials Processing Technology, 2007, 192–193: 1–7.

Neugebauer R, Putz M, Hellfritzsch U. Improved process design and quality for gear manufacturing with flat and round rolling [J]. Annals of the CIRP, 2007, 56(1): 307–312.

Fu X P, Dean T A. Past developments, current applications and trends in the cross wedge rolling process [J]. International Journal of Machine Tools and Manufacture, 1993, 33(3): 367–400.

Pater Z. Theoretical and experimental analysis of cross wedge rolling process [J]. International Journal of Machine Tools and Manufacture, 2000, 40(1): 49–63.

Wang Q, He F. A review of developments in the forging of connecting rods in China [J]. Journal of Materials Processing Technology, 2004, 151: 192–195.

Pater Z, Bartnicki J, Samołyk G. Numerical modelling of cross-wedge rolling process of ball pin [J]. Journal of Materials processing Technology, 2005, 164–165: 1235–1240.

Wang M, Li X, Du F. Current trends in cross wedge rolling for part forming [J]. ISIJ International, 2005, 45(11): 1521–1525.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the Structural Funds under the Innovative Economy Operational Programme (IE OP) financed from the European Regional Development Fund (No. POIG.0101.02-00-015/08)

Rights and permissions

About this article

Cite this article

Pater, Z., Gontarz, A. & Tofil, A. Analysis of the cross-wedge rolling process of toothed shafts made from 2618 aluminium alloy. J. Shanghai Jiaotong Univ. (Sci.) 16, 162–166 (2011). https://doi.org/10.1007/s12204-011-1119-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-011-1119-2