Abstract

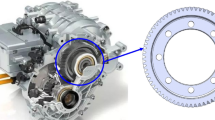

The heat treatment process of a gear made of AISI 9310 carburized steel is modeled using the commercial heat treatment simulation software DANTE. Both carburization and quenching processes affect the residual stress distribution and distortion of heat-treated parts, which are important to service quality and fatigue life. DANTE/VCARB is used to design the boost/diffuse schedule of a vacuum carburization process. Oil quenching is modeled following the vacuum carburization process. Thermal gradient and phase transformation are two main sources of distortion and residual stresses in quenched parts. The relation of the carbon distribution, thermal gradient, and phase transformations during quenching is studied through the gear modeling example. Because of geometry, the residual stress distribution after quenching is non-uniform along the gear surface. In general, the root fillet has higher residual compression than either the root or tooth face locations after traditional oil quenching of carburized gears. The predicted residual stresses from the oil quenching model are imported into a single tooth fatigue bending model. The gear stresses under bending load indicate the possible cracking locations during the bending fatigue test. The importance of heat treatment residual stresses during gear design is pointed out, and it is commonly ignored in the gear design and manufacturing industry.

Similar content being viewed by others

References

Freborg A, Ferguson B L, Li Z, et al. Bending fatigue strength improvement of carburized aerospace gears [C]// Proceedings of the 23rd ASM HTS Conference. Pittsburgh, PA: ASM Press, 2005: 186–195.

Li Z, Ferguson B L, Freborg A. Data needs for modeling heat treatment of steel parts [C]// Proceedings of Materials Science and Technology Conference. New Orleans, Louisiana: MST Press, 2004: 219–226.

Ferguson B L, Freborg A, Li Z. Residual stress and heat treatment: Process design for bending fatigue strength improvement of carburized aerospace gears [C]// Proceeding of 5th International Conference on Quenching and Control Distortion. Berlin: IFHTSE Press, 2007: 95–104.

Mackenzie S, Li Z, Ferguson B L. Effect of quenchant flow on the distortion of carburized automotive pinion gears [C]// Proceeding of 5th International Conference on Quenching and Control Distortion. Berlin: IFHTSE Press, 2007: 119–129.

Warke V, Sisson S, Makhlouf M. FEA model for predicting the response of powder metallurgy steel components to heat treatment [J]. Materials Science and Engineering A, 2009, 518(1–2): 7–15.

Bammann D. Development of a carburizing and quenching simulation tool: A material model for carburizing steels undergoing phase transformations [C]// Proceeding of 2nd International Conference on Quenching and Control of Distortion. Cleveland, OH: ASM Press, 1996: 367–375.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Zc., Ferguson, B.L. Computer modeling and validations of steel gear heat treatment processes using commercial software DANTE. J. Shanghai Jiaotong Univ. (Sci.) 16, 152–156 (2011). https://doi.org/10.1007/s12204-011-1117-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-011-1117-4