Abstract

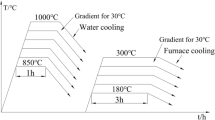

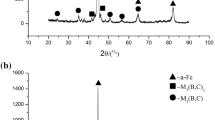

22MnB5 is one of the most typical hot stamping boron steels. In order to study the effect of austenitizing temperature and holding time on the mechanical properties of hot stamping boron steel 22MnB5, a series of quenching process are done. The tensile strength and hardness of 22MnB5 samples are measured. The results show that 22MnB5 has a good quenching performance, and the tensile strength and hardness of samples quenched in a water-cooled steel die are similar to those of water quenching. The higher tensile strength and HRC hardness are achieved when austenitizing at temperatures of 880–910 °C. Holding at 910 °C for 5 min and then quenching gives rise to a better combination of tensile strength, hardness and ductility.

Similar content being viewed by others

References

Li Hui-ping, Zhao Guo-qun, Zhang Lei, et al. The development status of hot stamping and quenching of ultra high-strength steel [J]. Journal of Shandong University (Engineering Science), 2010, 40(3): 69–74 (in Chinese).

Khan S H, Ahmed M S, Ali F, et al. Investigation of high strength steel bending [J]. Engineering Failure Analysis, 2009, 16(1): 128–135.

Hoffmann H, So H, Steinbeiss H. Design of hot stamping tools with cooling system [J]. CIRP Annals: Manufacturing Technology, 2007, 56(1): 269–272.

Bariani P F, Bruschi S, Ghiotti A, et al. Testing formability in the hot stamping of HSS [J]. CIRP Annals: Manufacturing Technology, 2008, 57(1): 265–268.

Lin Jian-ping, Wang Li-ying, Tian Hao-bin, et al. Research on hot forming behavior of ultrahigh strength steel [J]. Journal of Plasticity Engineering, 2009, 16(2): 180–183 (in Chinese).

Naderi M, Durrenberger L, Molinari A, et al. Constitutive relationships for 22MnB5 boron steel deformed isothermally at high temperatures [J]. Materials Science and Engineering A, 2008, 478(1–2): 130–139.

Tekkaya A E, Karbasian H, Homberg W, et al. Thermo-mechanical coupled simulation of hot stamping components for process design [J]. Computer Aided Engineering, 2007, 1(1): 85–89.

Xing Z W, Bao J, Yang Y Y. Numerical simulation of hot stamping of quenchable boron steel [J]. Materials Science and Engineering A, 2009, 499(1–2): 28–31.

He L F, Zhao G Q, Li H P. Measurement and analysis of time temperature transformation curves of boron steel 22MnB5 [J]. Applied Mechanics and Materials, 2010, 29–32: 484–489.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 50875154), the Program for Changjiang Scholars and Innovative Research Team in University of Ministry of Education of China (No. IRT931), the Postdoctoral Science Foundation of China (No. 200801408), and the Independent Innovation Foundation of Shandong University (No. 2010TS035)

Rights and permissions

About this article

Cite this article

He, Lf., Zhao, Gq., Li, Hp. et al. Research on mechanical properties of 22MnB5 steel quenched in a steel die. J. Shanghai Jiaotong Univ. (Sci.) 16, 129–132 (2011). https://doi.org/10.1007/s12204-011-1106-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-011-1106-7