Abstract

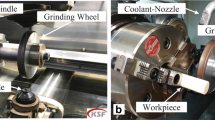

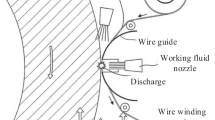

The technology of superabrasive grinding has been developed in order to achieve high-quality finish in extremely hard and brittle materials. Thereafter, truing and dressing technology on super abrasive grinding wheel is one of the most important subjects on precise machining field at present. In this paper, mist-jetting electrical discharge technology was applied to dressing metal-bonded superabrasive wheels. And a systematical study on the mechanism of selective removal of the bond was proposed. Experiments on dressing bronze bonded diamond grind wheels were carried out on a die-sinking electrical discharge machine. The diamond wheel topographies before and after electrical discharge dressing were observed by VH-800 3D digital microscope. The wheel profiles before and after dressing were observed. The results of electrical discharge dressing under different electrical parameters were compared. Experimental results indicate that the favorable surface topography can be obtained under suitable processing parameters and mist-jetting electrical discharge dressing (MEDD) is feasible for metal-bonded diamond grinding wheel.

Similar content being viewed by others

References

Ortega N, Sanchez J A, Aranceta J. Optimisation of grit protrusion in the electro-discharge dressing process of large grit size CBN grinding wheels [J]. Journal of Materials Processing Technology, 2002, 149: 524–529.

Syoji K. Truing and dressing of superabrasive wheels [J]. Machine and tools, 1989, 2: 18–26.

Zhang C, Shin Y C. A novel laser-assisted truing and dressing technique for vitrified CBN wheels [J]. Int J Machine Tools Manuf., 2002, 42: 825–835.

Sanchez J A, Ortega N, Luis N. Analysis of the electro discharge dressing (EDD) process of large-grit size CBN grinding wheels [J]. Int J adv manuf technol, 2005, 17(2): 147–154.

Murata R K, Tsutsumi C. Grinding of structural ceramics [C]// Symposium PED 16. [s.l.]:[s.n.], 1985: 261–272.

Ohmori H, Nakagawa T. Mirror surface grinding of siliconwafers with electrolytic in-process [J]. Ann. CIRP, 1990, 39(1): 329–332.

Babu N R, Radhakrishnan V. Investigations on laser dressing of grinding wheels, part I: preliminary study [J]. ASME Journal of engineering for industry, 1989, 111(3): 244–252.

Babu N R, Radhakrishnan V. Investigations on laser dressing of grinding wheels, part II: grinding performance of a laser dressed aluminum oxide wheel [J]. ASME Journal of engineering for industry, 1989, 111(3): 253–526.

Li L. Study on three dimensional laser ablation [J]. Chinese J Mechan. Engin., 1999, 31(2): 41–44.

Suzuki K, Uematsu T. On-truing/dressing of metal bond grinding wheels by electro-discharge machining [J]. Ann. CIRP, 1997, 36(1): 115–118.

Iwai M, Ichinose M, Qun H B. Application of fluid-free EDM to on-machine truing/dressing for superabrasive grinding wheels [C]//Proceedings of the XIII ISEM. Spain: Bilbao, 2001: 371–380.

Puertas I, Luis C J. A study on the machining parameters optimisation of electrical discharge machining [J]. Journal of materials processing technology, 2003, 143–144: 521–526.

Carslaw H S, Jaeger J C. Conduction of heat in solids[M]. London: Oxford University Press, 1959.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 50775143); the Research Fund for the Doctoral Program of Higher Education (No. 20060248031); the User program of Research Developing Center of Manufacturing Technology and Automatic Equipment.

Rights and permissions

About this article

Cite this article

Cai, Lr., Hu, Dj. & Jia, y. Mist-jetting electrical discharge dressing technology for superabrasive grinding wheels. J. Shanghai Jiaotong Univ. (Sci.) 13, 712–716 (2008). https://doi.org/10.1007/s12204-008-0712-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-008-0712-5