Abstract

Deep eutectic solvents (DESs) are a new class of green solvents analogous to ionic liquids due to their biodegradable capacity and low cost. However, the direct extractive desulfurization of diesel oil by DESs cannot meet the government’s standard. In this work, amphiphilic polyoxometalates were synthesized and characterized by FT-IR and mass spectrometry. The oxidative desulfurization results showed that benzothiophene (BT) could be completely removed by employing a [(C6H13)3P(C14H29)]3PMo12O40, DES (ChCl/2Ac) and H2O2 system. It was also found that the organic cation of catalysts played a positive role in oxidative desulfurization. The reaction conditions, such as reaction temperature and time, the amount of catalyst and DES and H2O2/S (O/S) molar ratio, were optimized. Different sulfides were tested to determine the desulfurization selectivity of the optimal reaction system, and it was found that 97.2% of dibenzothiophene (DBT) could be removed followed by 80.7% of 4-MDBT and 76.0% of 4,6-DMDBT. After reaction, the IR spectra showed that the catalyst [(C6H13)3P(C14H29)]3PMo12O40 was stable during the reaction process and the oxidative product was dibenzothiophene sulfone (DBTO2). Furthermore, the catalyst can be regenerated and recycled for four runs with little loss of activity.

Similar content being viewed by others

1 Introduction

Deep desulfurization of fuels is a worldwide topical issue because of the air pollution caused by SOx. Thus, increasingly strict regulations have been implemented to limit sulfur content in fuels to 10 ppm or even lower (Xiao et al. 2014; Zhang et al. 2018; Li et al. 2018; Liu et al. 2013; Wu et al. 2017). For example, since 2017 the sulfur content in diesel fuel and gasoline must be not higher than 10 ppm according to the latest standard in China. Hydrodesulfurization (HDS) is a classic technology that can remove most of the sulfides in fuels but can barely remove aromatic sulfides or needs harsh conditions such as temperature >370 °C and pressure >40 atm (Zeng et al. 2017; Zhang et al. 2016; Wu et al. 2016; Rafiee et al. 2016; Kianpour and Azizian 2016). Therefore, exploiting alternative or supplementary desulfurization approaches is highly desirable for petroleum refineries (Rezvani et al. 2018; Ja’fari et al. 2018; Zhang et al. 2017; Li et al. 2017a, b; Jiang et al. 2014a, b).

Extractive desulfurization is a feasible approach because of its simple and mild conditions (Nejad and Beigi 2015). The common extractants are organic solvents, ionic liquids and deep eutectic solvents (DESs) (Jiang et al. 2015; Li et al. 2016a, b, c; Zhao et al. 2016; Jiang et al. 2016; Zhang et al. 2018). Among the three types of solvent, DESs, a eutectic mixture of two or more components, are the most promising extractants due to their low cost and biodegradability. However, the extraction efficiency is still not very high in a one-step extraction. Li et al. (2016a, b, c) reported several tetrabutyl ammonium chloride-based DESs for extractive desulfurization and tetrabutyl ammonium chloride/polyethylene glycol (TBAC/PEG) showed 82.8% of desulfurization efficiency in one cycle. Hence, it is essential to extract for five cycles to reach deep desulfurization (Li et al. 2016a, b, c). Another sample using carboxylic acid-based DESs for extractive desulfurization was also faced with the obstacle of low desulfurization efficiency (Li et al. 2016a, b, c). Some researchers tried to add an oxidant to acidic DESs to establish a new desulfurization system, that is, extraction and catalytic oxidative desulfurization (ECODS) (Yin et al. 2015; Lu et al. 2015; Liu et al. 2016; Hao et al. 2017). Two p-toluenesulfonic acid-based DESs were employed as extractants and catalysts and H2O2 was used as oxidant for oxidation of benzothiophene (BT) and the desulfurization efficiency could reach up to 99.99% (Yin et al. 2015). Lu and his group (Lu et al. 2015) found that an oxalate-based DES showed good catalytic activity with H2O2 as an oxidant and 91% of dibenzothiophene (DBT) could be removed. Therefore, compared with extractive desulfurization, the oxidative desulfurization with DESs may be more promising due to its high activity. However, the reported DESs in oxidative desulfurization are very few probably owing to the difficulty of exploiting efficient DESs.

Polyoxometalates are commonly used in the field of catalysis because of their adjustable acid–base and redox properties over a wide range (Omwoma et al. 2015; Li et al. 2017a, b; Ma et al. 2017; Lu et al. 2017; Bertleff et al. 2017; Jiang et al. 2017; Chen et al. 2013). In our previous work, an oxidative desulfurization system with DESs as extractants was developed and commercial phosphotungstic acid (PTA) showed superior catalytic activity (Liu et al. 2016). However, it is difficult to separate and recycle the catalyst from the reaction system, and this may hinder the application of the PTA/DESs system. Thus, development of easily separable catalysts in the DESs system is necessary. In this work, amphiphilic polyoxometalates were introduced to acidic DESs to evaluate their catalytic performance. The main advantage is that these catalysts can be separated from the reaction system due to the fact that the DESs can be dissolved in water, but the catalysts amphiphilic polyoxometalates are insoluble. Then different DESs, catalysts with different cations and reaction conditions, with model oils with different aromatic sulfides, olefins and aromatics, were investigated.

2 Experimental

2.1 Preparation of catalysts and DESs

According to the method in the literature (Zhu et al. 2015a, b), a solution of trihexyltetradecyl phosphonium chloride ([(C6H13)3P(C14H29)]Cl; 1, 2, 3 mmol) in 20 mL of anhydrous ethanol was added dropwise into 50 mL of ethanol solution of H3PMo12O40·26H2O (1 mmol) while stirring for 4 h at room temperature. A bright yellow precipitate was formed, filtered and washed several times with anhydrous ethanol. Then, the catalysts, [(C6H13)3P(C14H29)]H2PMo12O40 (PH2Mo), [(C6H13)3P(C14H29)]2HPMo12O40 (PHMo) and [(C6H13)3P(C14H29)]3PMo12O40 (PMo), can be obtained by drying at 50 °C in vacuum for 24 h.

The DES ChCl/2Ac was simply prepared by mixing choline chloride (ChCl) with acetic acid (Ac) at a molar ratio of 1:2. The mixture was then warmed to 80 °C and stirred for 3 h. DES ChCl/2Fo and TBAC/2Ac were obtained according to the same process with formic acid (Fo) as a hydrogen bond donor and tetrabutylammonium chloride (TBAC) as a quaternary ammonium salt.

2.2 Desulfurization procedure

Preparation of model oils: The sulfur compounds including BT, DBT, 3-MBT, 4-MDBT and 4,6-DMDBT were dissolved in n-octane, respectively, with tetradecane as an internal standard. The sulfur contents of these model oils are 500 mg L−1.

The desulfurization tests were performed in a self-made two-necked flask, to which a certain amount of catalysts, DES, model oil and H2O2 were added in turn. The reaction mixture was stirred in a water bath at a set temperature for 3 h. The model oil in the upper layer was periodically withdrawn and analyzed by gas chromatography–flame ionization detection (GC-FID) with the analytical conditions listed in our previous work (Zheng et al. 2015; Jiang et al. 2014a, b).

3 Results and discussion

3.1 Characterization of catalysts

FT-IR spectra of H3PMo12O40, PMo, PHMo and PH2Mo are shown in Fig. 1. The peaks at 1065, 965, 870 and 790 cm−1 of H3PMo12O40 are attributed to the Keggin units. The prepared catalysts also have Keggin units because of their four characteristic peaks at 1065, 960, 881 and 809 cm−1. However, the shift of the absorption bands indicates electrostatic interactions between [(C6H13)3P(C14H29)]+ cations and [PMo12O40]3− anions (Xu et al. 2013). Compared with the IR spectrum of H3PMo12O40, the catalysts showed extra absorption peaks, such as the C–H stretching vibration at 2956, 2927 and 2855 cm−1 and the bending vibration of CH3 and CH2 at 1461, 1407 and 1379 cm−1. The weak band at 722 cm−1 indicates the bending vibration of –(CH2)n– (n > 4). Based on above discussion, the catalysts are prepared successfully by metathetical reaction. The mass spectra of these catalysts also confirmed this conclusion because they all show the same cation [(C6H13)3P(C14H29)]+ (m/z = 484) and anion [(C6H13)3P(C14H29) PMo12O40]2− (m/z = 1153).

3.2 Effect of the cation on sulfur removal

Organic cations may act as a phase transfer agent to adsorb the weakly polar sulfide molecules or as an emulsifying agent to stabilize emulsion droplets, which can enhance the catalytic ability of catalysts (Nisar et al. 2011; Xu, et al. 2013). Three Mo-based catalysts were prepared by changing the molar ratio of [(C6H13)3P(C14H29)]Cl and H3PMo12O40. As shown in Fig. 2, PH2Mo with 1 mol of organic cation per mol of catalyst exhibited the lowest desulfurization efficiency of 68.1%. The desulfurization efficiency increased to 79.6% with PMo as a catalyst, which had 3 mol of organic cation per mol of catalyst. Therefore, the catalytic activity of the catalyst could be enhanced by the organic cation. Acidity may promote the catalytic activity of catalysts according to the literature (Hao et al. 2017; Zhu et al. 2015a, b; Zhang et al. 2018). In this work, although the PH2Mo and PHMo are Brønsted acidic, their catalytic activities are still lower than the non-acidic PMo, suggesting that the organic cation plays a more important role than acidity.

3.3 Selection of a suitable DES

It is a challenge to select a suitable extractant because the extractant should be not dissolved in oil. IR spectra may be an effective analytical method to determine whether the acid DESs dissolve in oil owing to the characteristic absorption of the carbonyl group. Figure 3a plots the IR spectra of n-octane, n-octane saturated with ChCl/2Fo, n-octane saturated with ChCl/2Ac, and n-octane saturated with TBAC/2Ac. All samples presented the same absorption bands as n-octane, indicating the DESs cannot dissolve in the fuel. Figure 3b shows the desulfurization with the three DESs with PMo as a catalyst. The sulfur removal was only 10.0% without using an extractant. However, it increased to 88.5%, 95.6% and 63.6% with ChCl/2Fo, ChCl/2Ac and TBAC/2Ac as extractants, respectively. It can be concluded that DESs play an extremely positive role in oxidative desulfurization. Furthermore, the carbon chain length of DESs also greatly affects the desulfurization efficiency.

3.4 Optimization of reaction conditions for sulfur removal

In the above experiments, PMo combined with ChCl/2Ac showed the best desulfurization performance, and thus these were selected to evaluate a series of parallel experiments to systematically study the effects of different reaction conditions on sulfur removal.

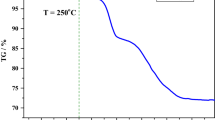

Different temperatures, such as 40, 50, and 60 °C, were tested for oxidative removal of DBT. Figure 4a shows that the sulfur removal was only 29.6% at 40 °C and 58.6% at 50 °C in 20 min, and it significantly improved to 81.7% as the temperature increased to 60 °C. However, the final sulfur removal at 60 °C was lower than that at 50 °C probably due to the kinetic competition of the unproductive decomposition of H2O2 (Yang et al. 2017). 50 °C might be the optimal reaction temperature, and the sulfur removal reached 97.2% at 120 min.

Effects of a temperature and time; b the amount of DES; c n(DBT)/n(catalyst) and d O/S molar ratio on desulfurization efficiency. Experimental conditions: model oil = 5 mL, a n(catalyst) = 0.0156 mmol, O/S = 4 (molar ratio), ChCl/2Ac = 2.5 mL; b O/S = 4, ChCl/2Ac = 2.5 mL, T = 50 °C; c EDS time = 10 min, n(catalyst) = 0.0156 mmol, O/S = 4, T = 50 °C, t = 120 min and d n(catalyst) = 0.0156 mmol, ChCl/2Ac = 2.5 mL, T = 50 °C

As shown in Fig. 4b, c, the amount of catalyst and extractant greatly affected the removal of DBT. The extractive desulfurization (EDS) rate was only 2.7% at V(DES)/V(model oil) = 1:5 and increased to 11.5% at V(DES)/V(model oil) = 3:5 (Fig. 4b). And the catalytic desulfurization rate was only 5.3% in the absence of DES (Fig. 4b). In order to obtain low-sulfur fuel, the amounts of catalyst and extractant were evaluated. The results showed that the 97.2% of DBT could be removed at V (DES)/V (model oil) = 2.5:5 and n(DBT)/n(catalyst) = 5:1. Thus, both the catalyst and extractant played important roles in sulfur removal. Figure 4c shows that the H2O2/S (O/S) molar ratio has a crucial influence on the sulfur removal. According to a previous report (Jiang et al. 2017), the decomposition of H2O2 is the competitive reaction to its oxidative reaction, resulting in an increase of H2O2 dosage. The sulfur removal increased from 72.8% at O/S = 2 to 97.2% at O/S = 4, and excessive H2O2 cannot promote the oxidation of DBT.

3.5 Oxidative removal of different sulfur compounds from model oil

It is well known that many kinds of aromatic sulfur compounds in diesel fuel are difficult to remove by HDS technology (Yun and Lee 2013; Li et al. 2016a, b, c). Consequently, it is important to investigate the desulfurization selectivity of different sulfur compounds. As shown in Fig. 5, BT can be removed completely. The removal of DBT can reach 97.2% followed by 4-MDBT (80.7%) and 4,6-DMDBT (76%). According to our previous work (Li, et al. 2016), the desulfurization efficiency was closely related to f+(r) Fukui function on the S site. The f+(r) values decrease in the order of BT > DBT > 4-MDBT > 4,6-DMDBT. It was found that the desulfurization selectivity of different sulfur compounds in this work was in accordance with the order of f+(r) Fukui function value.

3.6 Effects of fuel composition on sulfur removal

The actual fuel is complicated because of its components including olefins, aromatics and many other compounds (Xun et al. 2015; Wu et al. 2017; Xiao et al. 2014). In order to examine the effect of olefins and aromatics on sulfur removal, toluene, p-xylene and cyclohexene were added to the model oil with DBT as the modeled sulfur compound. Figure 6 shows that the sulfur removal decreased from 97.2% to 92.1%, 89.0% and 85.6% with the addition of 5 wt%, 10 wt% and 15 wt% toluene, respectively. The effect of p-xylene on sulfur removal was similar to that of toluene. However, the sulfur removal dropped sharply to 26.2% with addition of 10 wt% cyclohexene. Therefore, it could be concluded that cyclohexene was oxidized more easily than toluene, p-xylene and even DBT. It will be suggested that this desulfurization system should be used to treat actual fuels with a low concentration of olefins.

3.7 Reusability of the catalyst

The reusability and stability of the catalyst are undoubtedly important factors for industrial application. The oil was removed by decantation after reaction, and then the catalyst and oxidative product could be precipitated by adding deionized water into the DES phase. IR spectra of the fresh and used catalyst are plotted in Fig. 7, and the characteristic bands at 1065, 960, 881 and 809 cm−1 showed no destruction of the Keggin structure. Also, the peaks at 1290 and 1164 cm−1 were attributed to the stretching vibration of S=O in dibenzothiophene sulfone (DBTO2). The catalyst could be purified by washing the precipitate with ethyl ether several times. Then, the regenerated catalyst was evaluated with the addition of fresh model oil, DES and H2O2 under the optimal conditions. The results in Fig. 8 showed that the PMo could be recycled four times without a significant decline in activity.

4 Conclusion

A deep desulfurization system with DES as extractant was explored. BT could be removed completely with ChCl/2Ac as extractant and [(C6H13)3P(C14H29)]3PMo12O40 as catalyst, followed by DBT, 4-MDBT and 4,6-DMDBT. Two other catalysts [(C6H13)3P(C14H29)]2HPMo12O40 and [(C6H13)3P(C14H29)]H2PMo12O40 showed the lower activity than [(C6H13)3P(C14H29)]3PMo12O40, indicating the positive role of the long carbon chain cation of the catalysts. However, the long carbon chain of DESs exhibited a contrary role for oxidative desulfurization because the sulfur removal was 88.5% and 63.6% with ChCl/2Fo and TBAC/2Ac, respectively, while 95.6% with ChCl/2Ac. After reaction, the catalyst can be regenerated by water and recycled for at least four times. The reaction product was determined by IR spectra as DBTO2.

References

Bertleff B, Claussnitzer J, Korth W, Wasserscheid P, Jess A, Albert J. Extraction coupled oxidative desulfurization of fuels to sulfate and water-soluble sulfur compounds using polyoxometalate catalysts and molecular oxygen. ACS Sustain Chem Eng. 2017;5(5):4110–8. https://doi.org/10.1021/acssuschemeng.7b00087.

Chen X, Souvanhthong B, Wang H, Zheng H, Wang X, Huo M. Polyoxometalate-based ionic liquid as thermoregulated and environmentally friendly catalyst for starch oxidation. Appl Catal B. 2013;138:161–6. https://doi.org/10.1016/j.apcatb.2013.02.028.

Hao L, Wang M, Shan W, Deng C, Ren W, Shi Z, et al. L-proline-based deep eutectic solvents (DESs) for deep catalytic oxidative desulfurization (ODS) of diesel. J Hazard Mater. 2017;339:216–22. https://doi.org/10.1016/j.jhazmat.2017.06.050.

Ja’fari M, Ebrahimi SL, Khosravi-Nikou MR. Ultrasound-assisted oxidative desulfurization and denitrogenation of liquid hydrocarbon fuels: a critical review. Ultrason Sonochem. 2018;40:955–68. https://doi.org/10.1016/j.ultsonch.2017.09.002.

Jiang W, Zhu WS, Chang YH, Chao YH, Yin S, Liu H, et al. Ionic liquid extraction and catalytic oxidative desulfurization of fuels using dialkylpiperidinium tetrachloroferrates catalysts. Chem Eng J. 2014a;250:48–54. https://doi.org/10.1016/j.cej.2014.03.074.

Jiang W, Zhu WS, Li HM, Chao YH, Xun SH, Liu H, et al. Mechanism and optimization for oxidative desulfurization of fuels catalyzed by Fenton-like catalysts in hydrophobic ionic liquid. J Mol Catal A Chem. 2014b;382:8–14. https://doi.org/10.1016/j.molcata.2013.10.017.

Jiang W, Zhu WS, Li HP, Wang X, Yin S, Chang YH, et al. Temperature-responsive ionic liquid extraction and separation of the aromatic sulfur compounds. Fuel. 2015;140:590–6. https://doi.org/10.1016/j.fuel.2014.09.083.

Jiang W, Li H, Wang C, Liu W, Guo T, Liu H, et al. Synthesis of ionic-liquid-based deep eutectic solvents for extractive desulfurization of fuel. Energy Fuels. 2016;30(10):8164–70. https://doi.org/10.1021/acs.energyfuels.6b01976.

Jiang W, Zheng D, Xun S, Qin Y, Lu Q, Zhu W, et al. Polyoxometalate-based ionic liquid supported on graphite carbon induced solvent-free ultra-deep oxidative desulfurization of model fuels. Fuel. 2017;190:1–9. https://doi.org/10.1016/j.fuel.2016.11.024.

Kianpour E, Azizian S. Optimization of dispersed carbon nanoparticles synthesis for rapid desulfurization of liquid fuel. Pet Sci. 2016;13(1):146–54. https://doi.org/10.1007/s12182-015-0065-2.

Li CP, Zhang JJ, Li Z, Yin JM, Cui YN, Liu Y, et al. Extraction desulfurization of fuels with ‘metal ions’ based deep eutectic solvents (MDESs). Green Chem. 2016a;18(13):3789–95. https://doi.org/10.1039/c6gc00366d.

Li HP, Zhu WS, Zhu SW, Xia JX, Chang YH, Jiang W, et al. The selectivity for sulfur removal from oils: an insight from conceptual density functional theory. AIChE J. 2016b;62(6):2087–100. https://doi.org/10.1002/aic.15161.

Li J-J, Xiao H, Tang X-D, Zhou M. Green carboxylic acid-based deep eutectic solvents as solvents for extractive desulfurization. Energy Fuels. 2016c;30(7):5411–8. https://doi.org/10.1021/acs.energyfuels.6b00471.

Li S-W, Li J-R, Gao Y, Liang L-L, Zhang R-L, Zhao J-S. Metal modified heteropolyacid incorporated into porous materials for a highly oxidative desulfurization of DBT under molecular oxygen. Fuel. 2017a;197:551–61. https://doi.org/10.1016/j.fuel.2017.02.064.

Li S-W, Li J-R, Jin Q-P, Yang Z, Zhang R-L, Gao R-M, et al. Preparation of mesoporous cs-POM@MOF-199@MCM-41 under two different synthetic methods for a highly oxidesulfurization of dibenzothiophene. J Hazard Mater. 2017b;337:208–16. https://doi.org/10.1016/j.jhazmat.2017.04.037.

Li S-W, Yang Z, Gao R-M, Zhang G, Zhao J-S. Direct synthesis of mesoporous SRL-POM@MOF-199@MCM-41 and its highly catalytic performance for the oxidesulfurization of DBT. Appl Catal B. 2018;221:574–83. https://doi.org/10.1016/j.apcatb.2017.09.044.

Liu Y, She N, Zhao J, Peng T, Liu C. Fabrication of hierarchical porous ZnO and its performance in Ni/ZnO reactive-adsorption desulfurization. Pet Sci. 2013;10(4):589–95. https://doi.org/10.1007/s12182-013-0311-4.

Liu W, Jiang W, Zhu W, Zhu W, Li H, Guo T, et al. Oxidative desulfurization of fuels promoted by choline chloride-based deep eutectic solvents. J Mol Catal A Chem. 2016;424:261–8. https://doi.org/10.1016/j.molcata.2016.08.030.

Lu H, Li P, Deng C, Ren W, Wang S, Liu P, et al. Deep catalytic oxidative desulfurization (ODS) of dibenzothiophene (DBT) with oxalate-based deep eutectic solvents (DESs). Chem Commun. 2015;51(53):10703–6. https://doi.org/10.1039/c5cc03324a.

Lu H, Li P, Liu Y, Hao L, Ren W, Zhu W, et al. Synthesis of a hybrid Anderson-type polyoxometalate in deep eutectic solvents (DESs) for deep desulphurization of model diesel in ionic liquids (ILs). Chem Eng J. 2017;313:1004–9. https://doi.org/10.1016/j.cej.2016.10.140.

Ma W, Xu Y, Ma K, Luo Y, Liu Y, Zhang H. Synthesis of PW11Sn/TiO2 nanofibre catalytic materials with tunable rutile/anatase phase and application in ultra-deep desulfurization. Mol Catal. 2017;433:28–36. https://doi.org/10.1016/j.mcat.2016.12.024.

Nejad NF, Beigi AAM. Efficient desulfurization of gasoline fuel using ionic liquid extraction as a complementary process to adsorptive desulfurization. Pet Sci. 2015;12(2):330–9. https://doi.org/10.1007/s12182-015-0020-2.

Nisar A, Zhuang J, Wang X. Construction of amphiphilic polyoxometalate mesostructures as a highly efficient desulfurization catalyst. Adv Mater. 2011;23(9):1130–5. https://doi.org/10.1002/adma.201003520.

Omwoma S, Gore CT, Ji Y, Hu C, Song Y-F. Environmentally benign polyoxometalate materials. Coord Chem Rev. 2015;286:17–29. https://doi.org/10.1016/j.ccr.2014.11.013.

Rafiee E, Sahraei S, Moradi GR. Extractive oxidative desulfurization of model oil/crude oil using KSF montmorillonite-supported 12-tungstophosphoric acid. Pet Sci. 2016;13(4):760–9. https://doi.org/10.1007/s12182-016-0127-0.

Rezvani MA, Shaterian M, Akbarzadeh F, Khandan S. Deep oxidative desulfurization of gasoline induced by PMoCu@MgCu2O4-PVA composite as a high-performance heterogeneous nanocatalyst. Chem Eng J. 2018;333:537–44. https://doi.org/10.1016/j.cej.2017.09.184.

Wu PW, Zhu WS, Chao YH, Zhang JS, Zhang PF, Zhu HY, et al. A template-free solvent-mediated synthesis of high surface area boron nitride nanosheets for aerobic oxidative desulfurization. Chem Commun. 2016;52(1):144–7. https://doi.org/10.1039/c5cc07830j.

Wu P, Yang S, Zhu W, Li H, Chao Y, Zhu H, et al. Tailoring N-terminated defective edges of porous boron nitride for enhanced aerobic catalysis. Small. 2017;13:1701857. https://doi.org/10.1002/smll.201701857.

Xiao J, Wu L, Wu Y, Liu B, Dai L, Li Z, et al. Effect of gasoline composition on oxidative desulfurization using a phosphotungstic acid/activated carbon catalyst with hydrogen peroxide. Appl Energy. 2014;113:78–85. https://doi.org/10.1016/j.apenergy.2013.06.047.

Xu J, Zhao S, Ji Y, Song Y-F. Deep desulfurization by amphiphilic lanthanide-containing polyoxometalates in ionic-liquid emulsion systems under mild conditions. Chem Eur J. 2013;19(2):708–14. https://doi.org/10.1002/chem.201202595.

Xun SH, Zhu WS, Zhu FX, Chang YH, Zheng D, Qin YJ, et al. Design and synthesis of W-containing mesoporous material with excellent catalytic activity for the oxidation of 4,6-DMDBT in fuels. Chem Eng J. 2015;280:256–64. https://doi.org/10.1016/j.cej.2015.05.092.

Yang H, Jiang B, Sun Y, Zhang L, Sun Z, Wang J, et al. Polymeric cation and isopolyanion ionic self-assembly: novel thin-layer mesoporous catalyst for oxidative desulfurization. Chem Eng J. 2017;317:32–41. https://doi.org/10.1016/j.cej.2017.01.135.

Yin J, Wang J, Li Z, Li D, Yang G, Cui Y, et al. Deep desulfurization of fuels based on an oxidation/extraction process with acidic deep eutectic solvents. Green Chem. 2015;17(9):4552–9. https://doi.org/10.1039/c5gc00709g.

Yun G-N, Lee Y-K. Beneficial effects of polycyclic aromatics on oxidative desulfurization of light cycle oil over phosphotungstic acid (PTA) catalyst. Fuel Process Technol. 2013;114:1–5. https://doi.org/10.1016/j.fuproc.2013.03.035.

Zeng X, Xiao X, Li Y, Chen J, Wang H. Deep desulfurization of liquid fuels with molecular oxygen through graphene photocatalytic oxidation. Appl Catal B. 2017;209:98–109. https://doi.org/10.1016/j.apcatb.2017.02.077.

Zhang X, Shi Y, Liu G. Direct preparation of [(CH3)3NC16H33]4Mo8O26 and its catalytic performance in oxidative desulfurization. Catal Sci Technol. 2016;6(4):1016–24. https://doi.org/10.1039/c5cy01439e.

Zhang X, Huang P, Liu A, Zhu M. A metal-organic framework for oxidative desulfurization: Uio-66(Zr) as a catalyst. Fuel. 2017;209:417–23. https://doi.org/10.1016/j.fuel.2017.08.025.

Zhang H, Zhang Q, Zhang L, Pei T, Dong L, Zhou P, et al. Acidic polymeric ionic liquids based reduced graphene oxide: an efficient and rewriteable catalyst for oxidative desulfurization. Chem Eng J. 2018;334:285–95. https://doi.org/10.1016/j.cej.2017.10.042.

Zhao H, Baker GA, Wagle DV, Ravula S, Zhang Q. Tuning task-specific ionic liquids for the extractive desulfurization of liquid fuel. ACS Sustain Chem Eng. 2016;4(9):4771–80. https://doi.org/10.1021/acssuschemeng.6b00972.

Zheng D, Zhu WS, Xun SH, Zhou MM, Zhang M, Jiang W, et al. Deep oxidative desulfurization of dibenzothiophene using low-temperature-mediated titanium dioxide catalyst in ionic liquids. Fuel. 2015;159:446–53. https://doi.org/10.1016/j.fuel.2015.06.090.

Zhu W, Dai B, Wu P, Chao Y, Xiong J, Xun S, et al. Graphene-analogue hexagonal BN supported with tungsten-based ionic liquid for oxidative desulfurization of fuels. ACS Sustain Chem Eng. 2015a;3(1):186–94. https://doi.org/10.1021/sc5006928.

Zhu Y, Zhu M, Kang L, Yu F, Dai B. Phosphotungstic acid supported on mesoporous graphitic carbon nitride as catalyst for oxidative desulfurization of fuel. Ind Eng Chem Res. 2015b;54(7):2040–7. https://doi.org/10.1021/ie504372p.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 21506080 and 21766007), Natural Science Foundation of Jiangsu Province (No. BK20150485), Advanced Talents of Jiangsu University (No. 15JDG053) and A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Edited by Xiu-Qin Zhu

Handling editor: Wenshuai Zhu

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Jiang, W., Jia, H., Zheng, Z. et al. Catalytic oxidative desulfurization of fuels in acidic deep eutectic solvents with [(C6H13)3P(C14H29)]3PMo12O40 as a catalyst. Pet. Sci. 15, 841–848 (2018). https://doi.org/10.1007/s12182-018-0263-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-018-0263-9