Abstract

Grape pomace is a rich source of bioactive compounds and dietary fiber. This study aims to valorize the grape pomace by microwave-vacuum-assisted drying and extraction, which is a novel, green, and clean label technology. The drying and extraction of bioactive compounds from the grape pomace was optimized using response surface methodology. Box-Behnken design was used for three process variables, i.e., time, power, and vacuum levels. The highest drying rate was observed (5.53 g/100 g min after 10 min of drying) at the combination of 80 W and 20 inHg. This combination significantly reduced the drying time (25%) and resulted in the highest yield (64.5%) of bioactive compounds. Equally, changes in moisture ratio behavior were rapid under these processing conditions. Furthermore, Midilli model (R2 = 0.999, RMSE = 0.002, SSE = 3.71 × 10−6) was the best to justify the fitness of experimental values with predicted values. In addition, the diffusion coefficient, activation energy, and extraction yield were increased with increase in power and pressure. The concentration of bioactive components was higher in dried pomace compared to the extract. The extraction was successfully achieved without the use of solvent and the characteristics of extracted phenolics remained unaltered. Based on these findings, the microwave-vacuum-assisted drying and extraction process can be claimed as a sustainable approach.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

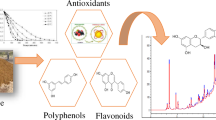

Grapes, scientifically known as “Vitis vinifera L.,” is a fruit of high economical value that is produced worldwide. It is a rich source of antioxidants, vitamins, minerals, and other micronutrients. In addition to the fresh consumption, it is also used to produce wine and juice. This process produces a huge waste (~ 18 million tone) in the form of pomace (Moro et al., 2021). Grape pomace (20–30% of the weight of grapes) consists of stem, skin, seeds, and small proportion of juice (Bao et al. 2020). A small amount of pomace is used as animal feed and the rest is either utilized as fertilizer or submitted to incineration and landfill (Drevelegka and Goula 2020). Disposal of large amount of pomace may have severe environmental impacts, such as soil and water pollution, soil acidification, and oxygen depletion in soil (Nakov et al. 2020).

Nevertheless, various studies on the composition of grape pomace have revealed that it is a source of macronutrients (especially dietary fiber) and contains bioactive components (BACs) (Goula et al. 2016; Kwiatkowski et al. 2020). Among these BACs, phenolic acids, pro-anthocyanidins, flavanols, anthocyanins, flavonols, and stilbenes are the most common. These BACs have several human health benefits, including prevention of molecular oxidation, inhibition of heart disease, anti-inflammatory, and anti-carcinogenic action (Averilla et al. 2019; Sies and Jones 2020). Thus, efforts are being made to extract these functional compounds through various extraction techniques (El Darra et al. 2013; Bubalo et al. 2016). These techniques use various types of solvents and pose a threat to environment, while increasing processing time and energy consumption. These traditional techniques are also inefficient to explore the potential of such valuable agro-food by-products. This has led to the search for rapid and cost-effective technique for the of extraction bioactive components (Moro et al. 2021).

In this regard, microwave has potential for the extraction of BACs without the use of solvents. This technique has been used for the extraction of BACs from various plant matrix including fenugreek, ginger, and onion (Brahim et al. 2014; Drevelegka and Goula 2020; Kwiatkowski et al. 2020; Khan et al. 2021). It is an efficient, economical, and clean alternative due to it speed, low energy consumption, and lack of solvents use (Khan et al. 2021; Alvi et al. 2022); however, to the best of our knowledge, the use of microwave with vacuum has not been investigated for extraction and drying of grape pomace. The aim of our research was to optimize the microwave-vacuum technique for the extraction of bioactive compounds with simultaneous drying of grape pomace. Subsequently, the evaluation of phenolic compounds in the extract, the antioxidant activity of pomace before and after the extraction was carried out. Moreover, physicochemical analysis, process efficiency, and energy utilization were determined.

Materials and methods

Preparation of Sample

Mature grapes (Sundar khani) were purchased from the local market of Faisalabad (Pakistan) and subjected to preparatory operations such as trimming of rachis and peduncle, sorting for damaged and overripe grapes. Then, a washing was carried with tap water to remove dust and dirt. The fruit was then blended and the resulting mixture was poured over the sieve to separate the juice (permeate) and pomace (retentate). The pomace was placed in the refrigerator at 10 °C for 3 h to separate the juice that is not well bound. Then, extraction and drying were carried out, followed by physicochemical analysis.

Drying and Extraction Process

The drying of grape pomace with simultaneous extraction of bioactive compound was carried out in a specifically designed instrument, as reported earlier by Khan et al. (2021). The grape pomace sample weighing 100 g was placed in the reactor. The process variables like power (30, 50, and 80 W), vacuum (10, 15, and 20 inHg), and time (5, 10, and 15 min) were chosen as per Box-Behnken design (BBD). This design was used to optimize the drying conditions, which are coded in Table 1. During the process, the water flow rate through the condenser (16 °C) was maintained at 100 mL/min to assist in the condensation of the vapors. The dried pomace and recovered vapors were stored in polyethylene bottles at room temperature until further analysis.

Drying Rate

Changes in weight of pomace as a function of time during drying was used in the following equation to calculate the drying rate (g moisture/100 g min):

Here, mt (g) is the moisture in the product at time t, mt+dt (g) is the moisture at time t + dt, and t and t + dt (min) are the initial time and time after specific interval, respectively.

Moisture Ratio

Moisture ratio, the relative amount of moisture removed, was calculated by the following equation:

Here, mo, mt and me are the moisture contents initially, at time t and at equilibrium, respectively. Moisture ratio calculated from the above equation was compared with different model Eqs. (3)–(6) as given below.

Diffusion Coefficient

Diffusion coefficient in a unsteady-state drying process was determined by Fick’s law of diffusion, written as;

Diffusion coefficient was calculated from the slope of line (α) drawn between ln (MR) and time as;

Here, D, t and L are effective diffusion coefficient (m2/s), time (s) and thickness (m) of the sample layer distributed in the drying chamber, respectively.

Antioxidant Activity

The antioxidant activity of dried grape pomace and vapor extract were calculated using the DPPH assay (Khan et al. 2020). The reaction mixture was prepared by adding 0.5 mL of extract (ethanolic/microwave) in 0.3 mL of 0.5 mM DPPH solution and 3 mL of ethanol. For vapor extracts, 50 μL of vapor extract was mixed with 5 mL of 0.004% DPPH solution. The mixture was placed in the dark for 30 min and the absorbance was measured at 515 nm using UV/vis spectrophotometer (STA-8200 V, Stalwart Analytics, Germany). DPPH activity (%) was calculated as:

Here, As and Ao are the values of absorbance of sample and DPPH solution, respectively.

Total Phenolic Contents

The total phenolic contents in grape pomace and vapor extract was estimated using the Folin-Ciocalteu method (Loizzo et al. 2019). 0.5 mL of prepared extract (0.8 g pomace/L ethanol) and 0.5 mL of vapors were separately mixed with 2.5 mL of tenfold diluted Folin reagent and 2 mL of sodium carbonate (40 g/L). The absorbance of the prepared mixture was measured at 765 nm after keeping the samples in dark for 2 h at room temperature. The total phenolic contents were quantified in terms of mg gallic acid equivalent (GAE) per gram of grape pomace and per milliliter of vapor extract by comparing the absorbance with the standard curve of gallic acid.

Total Flavonoid Contents

Total flavonoids in dried grape pomace and extract were measured following the protocol of (Loizzo et al. 2012). 0.5 mL of the sample (200 g/L) was mixed with 0.3 mL of sodium nitrite (5%) and aluminum chloride (10%). Distilled water was added to make a volume of 5 mL of the solution. Two milliliters of sodium hydroxide (NaOH, 1 M) was added in the solution. All samples were placed at room temperature before absorbance was measured at 415 nm in a UV/vis spectrophotometer (STA-8200 V, Stalwart Analytics, Germany). The quercetin standard curve was used to quantify the total flavonoids and was expressed as mg of quercetin equivalent (QE) per gram of dried pomace and per milliliter of extract.

Fourier Transform Infrared (FTIR) Spectroscopy

The samples were analyzed to identify functional groups using an FTIR spectrometer (Bruker Tensor 27) with attenuated total reflector (ATR), DLATGS detector using spectral range of 400–6000 cm−1 with a standard KBr beam splitter (Pasha et al. 2021). The samples were analyzed and the spectra peaks interpreted via OPUS software (Bruker Optik GmbH, Ettlingen).

Encapsulation of Extract

The condensed extract, obtained during drying process, was encapsulated in sodium alginate (2%, w/v) solution. The sodium alginate solution and the extract were mixed under stirring (200 rpm) and heating (70 °C) to facilitate thorough dispersion. The solution was dripped through the kit (Hydocs, pore size 0.45 mm) into calcium chloride solution (1%, w/v). The drip speed was maintained at 4.54 mL/min with the 15 cm distance between the kit nozzle and the solution. The resulting capsules were left in the calcium chloride solution for 10 min. Then, the capsules were separated and washed with deionized water to remove excess calcium and prevent complexation process (da Silva Carvalho et al. 2019). Additionally, the encapsulation efficiency of the alginate-extract capsules was measured by dividing the TPC of the capsules by the TPC of extract (Stojanovic et al. 2012).

Here, TPCm is the total phenolic contents in the microcapsules and TPCs is the total phenolic contents in the polymer-extract solution.

Statistical Analysis

In this study, Box-Behnken design (BBD) was chosen for modelling the process variables (power, time, and pressure). The response surface methodology (RSM) was applied to evaluate the influence of power and pressure on the drying rate and moisture ratio of grape pomace. The regression models were constructed for three parameters using the experimental design presented in Table 1. Finally, a comparison between the estimated with predicted values was carried out through R2, RMSE, SSE, chi-square, and RPD value.

Results and Discussions

Drying Rate

A model equation for drying rate was obtained by RSM analysis controlling for the processing variables and expressed in Eq. (15). The ANOVA results indicated that the P-value (< 0.0001) was lowest value and revealed that model equation was highly significant at P ≤ 0.05 (Table 2). The quadratic model had a coefficient of determination (R2) of 0.989; the adjusted R2 of 0.975 and predicted R2 of 0.809 were close as the difference was ~ 0.180. The adjusted R2 is the variance proportion in the output that is predictable from the input that in the real sense had effects on the output, whereas the predicted R2 is an indicator of how well a regression model predicts the outputs for new observations (Chakraborty et al. 2011). Thus, statistical evaluation indicates that the model equation can be used to predict the maximum values of drying rate.

The DR of grape pomace (subjected to different levels of power, vacuum, and time) is plotted in Fig. 1. The DR increased with increasing power levels (Fig. 1a). It was the lowest (between 1.1 and 1.2 g/100 g min after 30 min for all pressure levels) at 30 W and continued to increase even after 30 min of processing. This may be due to slow heating at this power. With the increase in power (30 to 50 W), the DR value reached to 1.25 g/100 g min within 5 min, which was the higher value than 30 W. Moreover, the drying time was 6 times reduced compared to the lowest power level. Similarly, the DR reached at 3.16 g/100 g min in 3 min at 80 W, which was the highest value of DR in the lowest time of processing.

Presumably, the increase in power rapidly excited the physically bound water molecules and caused them to leave off the surface of pomace. This reduced the drying time by about threefold at 80 W compared to 30 W. After the maximum drying rate (5.53 g/100 g min) was reached in 10 min at 80 W, further processing resulted in reduction of drying rate as moisture contents in pomace were reduced. Similar trends have already been reported in literature, and thus, increasing the power level significantly increased the DR and decreased the processing time from 30 to 3 min.

The DR increased significantly with increasing vacuum level inside the drying chamber (Fig. 1b). The combined effect of power and vacuum revealed that drying rate was uppermost at higher pressure levels. The maximum value observed was 5.53 g/100 g min after 10 min of drying at 20 in Hg and 80 W (Fig. 1c). This could be due to the vacuum inside the chamber which rapidly removed all the moisture produced during drying process and maintained the moisture gradient inside the drying chamber. The similar trend was reported by Suna (2019) during the vacuum drying of medlar fruit leather.

While pressure and power levels were important factors controlling the rate of moisture removal, a falling rate period started after 30 min of drying at 30 W (Fig. 1d). At higher power levels, the drop-off period started earlier than the low power levels (12 and 15 min for 80 and 50 W, respectively). This could be associated with the increase in temperature inside the drying chamber with increasing power. These findings were in line with the results of those who used this technique for the drying of onion and ginger. Therefore, it can be concluded that higher power (P) and vacuum levels (V) can be efficiently employed to improve the drying rate and rapidly remove the moisture contents form the product. The optimized conditions for the drying rate were 80 W, 20 inHg, and 10 min.

Moisture Ratio

Moisture ratio describes the relative moisture loss of the product and was used to determine the drying kinetics of grape pomace. A model equation was obtained by RSM analysis including three processing variables and expressed in Eq. (16). The ANOVA results indicated that P-value (< 0.0001) had the lowest values and revealed that the model equation was highly significant at P ≤ 0.05 (Table 2). The quadratic model had R2 of 0.998, the adjusted R2 of 0.994, and predicted R2 of 0.961 were quite close as the difference was ~ 0.037 (Chakraborty et al. 2011). Thus, the statistical evaluation indicates that the model equation can be used to predict the maximum values of drying rate.

The variations in MR at different pressure and power levels throughout the drying process were sketched in Fig. 2. At 30 W, MR were 0.71 after 30 min of drying, and it was quickly reduced to minimum value of 0.15 after 20 min of drying at 80 W, while maintaining a vacuum of 20 inHg (Fig. 2d).

The vacuum facilitated drying and caused the lowest MR values at higher vacuum levels (20 inHg) at the constant microwave power. For instance, MR was observed as 0.29 at 10 inHg and was reduced to 0.17 at 20 inHg at 80 W power. This resulted in 2 times reduction of processing time. The maximum reduction (45%) in MR was observed at 80 W and 20 inHg during 5- to 10-min interval of drying. Higher power and pressure might remove the moisture faster, which then reduced the MR value. These results were in agreement with those who applied the vacuum-assisted microwave process for drying of dragon fruit.

The MR was predicted using different model equations and the results were compared with the experimental values. Statistical analysis (Table 4) revealed that the Midilli model was the best-fitting model, with a high R2 (0.999) and lowest RSME (0.002) and SSE (3.71 × 10−6) values followed by the logarithmic, and Page models for all the treatments. Thus, the Midilli model was the best fit to predict the behavior of MR (Table 3).

Antioxidant Activity and Phenolic Compounds

The phenolic compounds (DPPH, TPC, and TFC contents) of dried pomace and vapors are compared in Fig. 3. The DPPH contents of dried pomace were three times higher than those of fresh pomace (Fig. 3a). A non-significant effect of process variables (power and vacuum) was observed on DPPH contents. Besides, the TFC contents of dried pomace increased with increasing power up to 50 W. Then, it started to decrease with further increase in power level (Fig. 3e).

In dried grape pomace, TPC contents linearly increased with increasing vacuum and power levels (Fig. 3c). The TPC contents were higher in dried pomace compared to the fresh one. Furthermore, the maximum TPC values were observed at the highest power and vacuum levels. It can be observed that pomace revealed an improvement of 66% in TPC contents when the power and vacuum levels were changed from low to high. This can be attributed to the fact that the increase in power resulted in greater moisture removal over time and increased the solid contents of the pomace. This led to an increase in the value of phenolic compounds in the dried pomace and retained the bioactive compounds in pomace. Similarly, the TFC contents were also higher in the dried pomace than in the fresh pomace. Moreover, it is evident that pomace has better phenolic activity than solvent extraction.

Phenolic contents in vapors/extract (obtained by condensation) followed the trend of pomace (Fig. 3b, d, and f). However, the values were ten times lower in vapors compared to pomace. This indicates that most of the phenolic compounds were retained in pomace can be used as functional ingredients due to higher phenolic contents. Thus, the results revealed that dried pomace had higher values for all three phenolic contents. In addition, the extraction was higher without altering the phenolic performance.

Fourier Transform Infrared (FTIR) Spectroscopy

The functional groups of chemical compounds and their mode of vibrational motion in extract of grape pomace were examined using FTIR technique (Fig. 4).

The wavenumber ranges to identify various functional groups and their vibrational mode in the pomace extract are illustrated in Table 4. The peaks in the range of 3200–3400 cm−1 showed the presence of stretching of the hydroxyl group (—OH str) as discussed in (Olalere et al. 2021). The antisymmetric vibrational motion of the methyl group (—CH3) was observed in the range of 2952–2972 cm−1. The ranges of wavenumber 2500–3300 cm−1 and 900–950 cm−1 indicated the presence of carboxylic group (—COOH) as well as alcoholic group (—OH) with OH stretching and out of plane deformation motion, respectively. The peaks for the double (C = C) were analyzed in a narrow range of wavenumber between 1620 and 1680 cm−1. Nitro aromatic compounds were detected in a range of 1485 to 1555 cm−1.

The absorption intensity of the ether linkage (—O—) was measured in the range of 1020–1150 cm−1. The functional group of aromatic compounds were between 710 and 860 cm−1. The absorption bands for halogen groups such as fluorine (—F) and chlorine (—Cl) were 1000–1400 cm−1 and 540–760 cm−1, respectively. These wavenumber were ranges have been used to identify functional groups of chemical compounds in previous studies (Baltacıoğlu et al. 2021). The results indicated that there was more loss of phenolic compounds at higher microwave powers and vacuum levels compared to lower ones. This loss of functional compounds was due to the thermal degradation at high microwave power which caused the temperature to rise (Kutlu et al. 2021).

Encapsulation Efficiency

The recovered vapors were encapsulated in sodium alginate microbeads. Encapsulation of bioactive extract was aimed to entrap phenolic compounds for drug delivery applications. Experimental results revealed an encapsulation efficiency of 64 ± 2%, which was in agreement with the results of Moschona and Liakopoulou-Kyriakides (2018) who encapsulated the extract of wine waste of grape white lees, white mac, and red mark chitosan alginate beads and reported encapsulation efficiencies of 55, 77, and 79%, respectively. The higher efficiency of encapsulation indicated that encapsulate had potential for targeted delivery with a solvent free and cleanable extraction process.

Extraction Yield

The extraction efficiency, expressed as a percentage, is the ratio of the amount of moisture recovered (g) during the drying process to the total amount of moisture (g) present in the grape pomace (Fig. 5a). The vapor extraction efficiency was 38.72% at 30 W and 42.58% at 50 W at 10 inHg, respectively. Moreover, the experimental results revealed that the highest power (80 W) produced a maximum value of extraction yield (64.1%). The variation in yield may be attributed to the amount of heat provided by these microwave powers. As discussed earlier, the highest power resulted in maximum moisture removal from the pomace. Thus, maximum amount of vapors was condensed at 80 W.

Likewise, an increasing trend for yield was observed with increasing vacuum level (Fig. 5a). At a constant power of 30 W, increasing the vacuum resulted in 36.88% more moisture recovery from the pomace. This increase was low (10%) at 80 W with the increase in vacuum from 10 inHg to 20 inHg. However, the maximum recovery (70.51%) was observed at 80 W and 20 inHg. This might be due to the high power resulting in rapid removal of moisture from the pomace. Combined effect of pressure was significantly pronounced in this case. At the highest power and vacuum level, i.e., 80 W and 20 inHg, the extract yield was 33.04% higher than 30 W and 20 inHg of processing conditions.

Effective Diffusivity

The effect of different power and pressure levels on effective diffusivity (ED) during the drying of grape pomace had been drawn in Fig. 5b. It was observed that increase in power levels increased the diffusivity of moisture through the sample. ED value remained same, i.e., 2.43 × 10−7 for all vacuum levels at power of 30 W. However, ED value increased ~ 4 times with the increase in power from 30 to 50 W. This increase was even more pronounced at 80 W, i.e., 8.5, and 2 times compared to 30 and 50 W, respectively. Unlikely, effect of vacuum on ED was non-significant compared to power values; a slight increase in effective diffusivity was observed at 50 and 80 W. While no change in ED was observed at 30 W, similar results were reported by Raj and Dash (2020) who used microwave power and pressure for drying of dragon fruit slice.

Activation Energy

The effect of power and vacuum levels on the activation energy (Ea) of vapor molecules was analyzed (Fig. 5c). Increasing the power level caused an increase in activation energy of the product. For instance, the activation energy increased form 0.12 to 1.44 W/g as the power was increased from 30 to 80 W. This is a 12 time increase that can be attributed to the fact that high temperature produced at high power had rapidly excited the water molecules and caused them to leave the surface. Thus, activation energy during the drying process was increase for all power levels at constant pressure.

The vacuum also influenced an increase in activation energy of the product. An estimated 20% increase was observed when the pressure was increased from 10 to 15 in Hg at constant power (80 W), resulting in a rapid loss of product moisture. This was due to rapid suction of vapors produced by the vacuum, which produced moisture gradient and increased the activation energy requirement of the samples. A further increase in pressure did not significantly influence Ea values. Thus, power had a more significant effect on Ea values than pressure.

Specific Energy Consumption

Specific energy consumption (SEC) was measured as the energy consumption per kilogram of product during drying (Fig. 5d). Increasing the microwave power from 30 to 80 W maximally reduced the value of effective energy consumption from 3.57 to 1.3 kJ/kg, respectively, while keeping the vacuum constant (10 inHg). This represents a 63.58% reduction when the power was increased from 30 to 80 W at constant vacuum of 10 inHg. However, the lowest values of SEC were observed at 80 W for all pressure levels (1.3, 1.13, and 1.04 kJ/kg at 10, 15, and 20 inHg vacuum, respectively). This decrease may be attributed to the fact that the high microwave powers enhanced the excitation energy of the water molecules in the product to leave the product surface.

The effect of vacuum was also significant in reducing the SEC for pomace drying (P < 0.05). At constant power of 30 W, 28.8% reduction in SEC was observed when the vacuum was increased from 10 to 20 inHg. This was the maximum reduction in SEC contents in response to increasing negative pressure at constant power, which was less pronounced with increasing power and vacuum. However, the minimum SEC contents were observed at 20 inHg for all power levels (at 2.54, 2.06, and 1.04 kJ/kg at 30, 50, and 80 W power, respectively). These factors, in fact, reduced the drying time for the high vacuum-power combination, resulting in less energy consumption during the drying. Hence, a combination of high vacuum and power levels is recommended to save time, capital, and energy during the process (Fig. 5).

Conclusion

In the current study, microwave-vacuum-assisted drying was optimized for the drying of grape pomace as well as for the recovery of bioactive compounds. The combined effect of power and vacuum (80 W and 20 inHg) resulted in the highest value of drying rate 5.53 g/100 g min within 10 min of drying process. In addition, it rapidly reduced the moisture ratio, which reduced the processing time. Besides, the effective diffusion and activation energy were significantly influenced by power compared to vacuum levels. Furthermore, the total phenolic contents were not influenced by microwaves and the dried pomace contained more bioactive compounds than the extract (recovered vapors). The results indicated that microwave-vacuum extraction can be used as an environmentally friendly and clean label extraction technique.

Data Availability

All the data used in the manuscript are available in the tables and figures.

Code Availability

Not applicable.

References

Alvi T, Asif Z and Khan M K I (2022) Clean label extraction of bioactive compounds from food waste through microwave-assisted extraction technique-A review. Food Bioscience: 46:101580

Averilla JN, Oh J, Kim HJ, Kim JS, Kim J-S (2019) Potential health benefits of phenolic compounds in grape processing by-products. Food Sci Biotechnol 28(6):1607–1615

Baltacıoğlu H, Baltacıoğlu C, Okur I, Tanrıvermiş A, Yalıç M (2021) Optimization of microwave-assisted extraction of phenolic compounds from tomato: Characterization by FTIR and HPLC and comparison with conventional solvent extraction. Vib Spectrosc 113:103204

Bao Y, Reddivari L, Huang J-Y (2020) Enhancement of phenolic compounds extraction from grape pomace by high voltage atmospheric cold plasma. LWT 133:109970

Brahim M, Gambier F, Brosse N (2014) Optimization of polyphenols extraction from grape residues in water medium. Ind Crops Prod 52:18–22

Bubalo MC, Ćurko N, Tomašević M, Ganić KK, Redovniković IR (2016) Green extraction of grape skin phenolics by using deep eutectic solvents. Food Chem 200:159–166

Chakraborty R, Mukhopadhyay P, Bera M, Suman S (2011) Infrared-assisted freeze drying of tiger prawn: parameter optimization and quality assessment. Drying Technol 29(5):508–519

da Silva Carvalho AG, da Costa MMT, Barros HD, d F Q, Cazarin C B B, Junior M R M and Hubinger M D, (2019) Anthocyanins from jussara (Euterpe edulis Martius) extract carried by calcium alginate beads pre-prepared using ionic gelation. Powder Technol 345:283–291

Drevelegka I, Goula AM (2020) Recovery of grape pomace phenolic compounds through optimized extraction and adsorption processes. Chem Eng Process-Process Intensif 149:107845

El Darra N, Grimi N, Vorobiev E, Louka N, Maroun R (2013) Extraction of polyphenols from red grape pomace assisted by pulsed ohmic heating. Food Bioprocess Technol 6(5):1281–1289

Goula AM, Thymiatis K, Kaderides K (2016) Valorization of grape pomace: drying behavior and ultrasound extraction of phenolics. Food Bioprod Process 100:132–144

Khan MKI, Maan AA, Aadil RM, Nazir A, Butt MS, Rashid MI, Afzal MI (2020) Modelling and kinetic study of microwave assisted drying of ginger and onion with simultaneous extraction of bioactive compounds. Food Sci Biotechnol 29(4):513–519

Khan M K I, Ghauri Y M, Alvi T, Amin U, Khan M I, Nazir A, ... & Maan A A (2021) Microwave assisted drying and extraction technique; kinetic modelling, energy consumption and influence on antioxidant compounds of fenugreek leaves. Food Science Technol 42:56020.

Kutlu N, Isci A, Sakiyan O, Yilmaz AE (2021) Extraction of phenolic compounds from cornelian cherry (Cornus mas L.) using microwave and ohmic heating assisted microwave methods. Food Bioprocess Technol 14(4):650–664

Kwiatkowski M, Kravchuk O, Skouroumounis GK, Taylor DK (2020) Microwave-assisted and conventional phenolic and colour extraction from grape skins of commercial white and red cultivars at veraison and harvest. J Clean Prod 275:122671

Loizzo MR, Tundis R, Bonesi M, Menichini F, Mastellone V, Avallone L, Menichini F (2012) Radical scavenging, antioxidant and metal chelating activities of Annona cherimola Mill.(cherimoya) peel and pulp in relation to their total phenolic and total flavonoid contents. J Food Compos Anal 25(2):179–184

Loizzo MR, Sicari V, Pellicanò T, Xiao J, Poiana M, Tundis R (2019) Comparative analysis of chemical composition, antioxidant and anti-proliferative activities of Italian Vitis vinifera by-products for a sustainable agro-industry. Food Chem Toxicol 127:127–134

Moro KIB, Bender ABB, da Silva LP, Penna NG (2021) Green extraction methods and microencapsulation technologies of phenolic compounds from grape pomace: a Review. Food Bioprocess Technol 14(8):1407–1431

Moschona A, Liakopoulou-Kyriakides M (2018) Encapsulation of biological active phenolic compounds extracted from wine wastes in alginate-chitosan microbeads. J Microencapsul 35(3):229–240

Nakov G, Brandolini A, Hidalgo A, Ivanova N, Stamatovska V, Dimov I (2020) Effect of grape pomace powder addition on chemical, nutritional and technological properties of cakes. LWT 134:109950

Olalere OA, Gan CY, Akintomiwa OE, Adeyi O, Adeyi A (2021) Optimisation of microwave-assisted extraction and functional elucidation of bioactive compounds from Cola nitida pod. Phytochem Anal 32(5):850–858

Pasha I, Ahmad F, Usman M (2021) Elucidation of morphological characteristics, crystallinity, and molecular structures of native and enzyme modified cereal brans. J Food Biochem 45(7):e13768

Raj GB, Dash KK (2020) Microwave vacuum drying of dragon fruit slice: artificial neural network modelling, genetic algorithm optimization, and kinetics study. Comput Electron Agric 178:105814

Sies H, Jones DP (2020) Reactive oxygen species (ROS) as pleiotropic physiological signalling agents. Nat Rev Mol Cell Biol 21(7):363–383

Stojanovic R, Belscak-Cvitanovic A, Manojlovic V, Komes D, Nedovic V, Bugarski B (2012) Encapsulation of thyme (Thymus serpyllum L.) aqueous extract in calcium alginate beads. J Sci Food Agric 92(3):685–696

Suna S (2019) Effects of hot air, microwave and vacuum drying on drying characteristics and in vitro bioaccessibility of medlar fruit leather (pestil). Food Sci Biotechnol 28(5):1465–1474

Funding

Funding for open access charge Universidade de Vigo/CISUG. Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. We are thankful to Higher Education Commission, Islamabad-Pakistan for funding this research under the project number TDF-03–146. Thanks to GAIN (Axencia Galega de Innovación) for supporting this research (grant number IN607A2019/01).

Author information

Authors and Affiliations

Contributions

A. H.: conceptualization, methodology, investigation, validation, formal analysis, writing—original draft preparation; A. A. M.: methodology, investigation, validation, formal analysis, contribution in writing; M. K. I. K.: methodology, investigation, validation, formal analysis, and contribution in writing in relevant section; A. N.: data analysis, writing—review and editing, final draft supervision and monitoring. M. U. K.: review and editing, final draft supervision and monitoring; M. A. S.: review and editing, final draft supervision, and monitoring; M. R.: review and editing, final draft supervision, and monitoring; J. M. L.: review and editing, final draft supervision, and monitoring. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics Approval

Not applicable.

Consent to Participate

All authors has given their full consent to participate.

Consent for Publication

All authors has given their full consent for publication.

Conflict of Interest

Abdul Hameed declares that he no conflict of interest. Abid Aslam Maan declares that he no conflict of interest. Akmal Nazir declares that he no conflict of interest. Usman Amin declares that he no conflict of interest. Muhammad Kashif Iqbal Khan declares that he no conflict of interest. Muhammad Usman Khan declares that he no conflict of interest. Mohammad Ali Shariati declares that he no conflict of interest. Maksim Rebezov declares that he no conflict of interest. José M. Lorenzo declares that he no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hameed, A., Maan, A.A., Nazir, A. et al. Microwave-Vacuum Extraction Technique as a Green and Clean Label Technology: Kinetics, Efficiency Analysis, and Effect on Bioactive Compounds. Food Anal. Methods 16, 525–540 (2023). https://doi.org/10.1007/s12161-022-02437-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-022-02437-6

control,

control,

10 inHg,

10 inHg,

15 inHg, and ■ 20 inHg

15 inHg, and ■ 20 inHg

10 inHg,

10 inHg,

15 inHg, and ■ 20 in of Hg) on extraction yield (a), effective diffusivity (b), activation energy (c), and specific energy consumption (d)

15 inHg, and ■ 20 in of Hg) on extraction yield (a), effective diffusivity (b), activation energy (c), and specific energy consumption (d)