Abstract

The use of mechanically separated meat (MSM) from poultry in meat and sausage products is subject to declaration. Current methods such as microscopy or calcium analysis have proven to be insufficient to ensure the specific detection of MSM in meat and sausage products. When using MSM during production, intervertebral disc and cartilage specific proteins from chicken unavoidably end up in the sausages. Thus, a pseudo-MRM-LC–MS/MS-based assay was developed and validated, which uses intervertebral disc and cartilage specific peptides to detect MSM in meat and sausage products. All five marker peptides were assigned to collagen II alpha 1 which makes up a large part of the proteome of intervertebral discs and cartilage. In order to evaluate the validity of the methodology, a total of 23 positive controls (MSM content 5–90%) and a total of 19 negative controls were examined in a blinded study. After unblinding, 22 of 23 positive controls were correctly classified. Only one self-produced sample with 5% MSM was declared as a negative case (overall sensitivity 96%). In contrast, all negative controls were correctly classified as negative (specificity 100%). In summary, the LC–MS/MS assay allowed the specific detection of MSM in real samples with unknown composition down to 10% MSM in the meat content.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The substitution of high-priced with low-priced ingredients can be observed in the food industry, e.g., the “horse meat scandal in 2013” (Premanandh 2013) or silver-medal awarded sausages which were made from mechanically separated meat (MSM) (Deter 2018).

According to the Directive Regulation (EC) No. 853/2004 (European Commission 2004), MSM is a product that is “obtained by removing meat from flesh-bearing bones after boning or from poultry carcases, using mechanical means resulting in the loss or modification of the muscle fibre structure.” MSM from poultry or pigs is subject to labeling but its use in food preparations is generally permitted. In contrast, MSM from cattle, sheep and goats, is not allowed in EU due to health concerns (European Commission 2001). Another — possibly not labeled — ingredient in sausages is chicken skin. This is normally used in animal feed but may be sufficient to label a sausage as a poultry sausage (European Commission 2010).

In 2010 and 2011, around 129,000 tons (64, 000 t from poultry and pork, respectively; European Commission 2013) of mechanically separated meat (MSM) also referred to as mechanically deboned meat or mechanically recovered meat were produced in Germany alone. As stated by the European Commission, a total of 60,000 tons of MSM from poultry and pork were exported to other member states or to third countries. In conclusion, the whereabouts of an additional total of 70,000 tons of MSM remained unknown (European Commission 2015, Foodwatch 2014).

MSM is currently detected microscopically via the visual detection of bone fragments from the meat sample, which may contaminate the meat pulp due to the mechanical production process (Tremlova et al. 2006; Mohamed et al. 2016; Langen & Horn 2020). The verification is complex and lengthy and does not always have the desired reliable results, since only a small portion of the sample is analyzed (Pospiech et al. 2019). In addition, increased calcium content, resulting from bone fragments, can be an indicator of mechanically separated meat (European Commission 2005). This detection also has a very limited sensitivity, since the calcium content in MSM can be adjusted to inconspicuous values during production (personal communication). Furthermore, antibody-based methods have proven unsuitable in the past (Pickering et al. 1995).

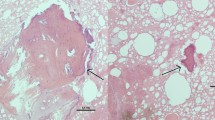

Iammarino et al. (2020) described a new effort for the detection of mechanically separated meat using the 90Sr content in meat and sausage products. The precision of the method was 61% and could be increased to 87% with the help of further investigation parameters (Ca-, 88Sr-, and ash content). Mohamed et al. (2016) investigated commercial and experimentally produced emulsion-type sausages formulated with 0, 10, 30, 50, 70, and 90% mechanically recovered poultry meat (MPRM). These sausages were examined for ash, bones, cartilage, and calcium content. In addition, histological sections were investigated after staining with H&E and Trichrome blue. In summary, the addition of 10% of MRPM could not be detected, whereas 30% or more MRPM were detected due to significant changes in technological properties, as well as induced structural changes in bone and cartilage content. Similar studies using Raman spectroscopy were performed by Wubshet et al. (2019). Based on 79 MSM samples, a rapid method to determine the calcium and ash content of MSM-derived bones and meat mixtures was developed. Recently, Wieja et al. (2021) described a new method to classify different MSM-types. Ultrasound was used, and the ultrasound velocity of minced hand deboned chicken fillets and low/high pressure MSM from chicken carcasses/collarbones differed significantly. The methods are proposed to be used in an industrial process control to determine the protein, fat and sodium content (Wieja et al. 2021), or the ash and calcium content (Wubshet et al. 2019), respectively.

Since there is a suspicion that the labeling requirements for MSM are not fulfilled in all cases, there is a need for better corresponding detection methods. According to the German Agricultural Society (DLG), a reliable detection of MSM, added hydrolyzed proteins or blood plasma in meat products, has so far not been possible without a doubt. In order to overcome such deficits, new modern analytical methods such as LC–MS/MS-based proteomic approaches are becoming popular for food authentication (Ortea et al. 2016; Fiorino et al. 2019; Hassoun et al. 2020; Nolleta and Ötleş 2020). Recently, an official governmental working group was founded in Germany with the aim of detecting food fraud with the help of protein analysis (Stoyke et al. 2019). Current applications include a method for the detection of transglutaminase (Jira and Schwägele 2017), the addition of porcine blood plasma (Stader et al. 2019), and the detection of allergens or authenticity checks for food products (Fiorino et al. 2019; Johnson and Downs 2019; Lasch et al. 2019; Ruhland and Klinger 2019; Stoyke et al. 2019). Whereas the latter include the detection of one species in another, e.g., pork in beef products (exemplarily von Bargen et al. 2013; von Bargen et al. 2014), until now, a distinction of different parts of one species, which would be necessary for the detection of MSM in meat products, is an unsolved challenge.

A first effort by Surowiec et al. (2011) used the combination of an off-gel electrophoresis with LC–MS/MS to define potential marker peptides for MSM. Subunits of hemoglobin and myosin-binding protein C were identified but showed little significance, since differences in concentrations of these proteins between muscle tissue and MSM only depended on the type of MSM production (Surowiec et al. 2011).

Thus, new approaches, not using meat tissue for discrimination, must be discussed. Due to the production process, MSM contains not only meat but also intervertebral disc material as well as, for example, cartilage, tendon, periosteum bone marrow, or bone (Trindade et al. 2004). For an alternative (new) method, it is therefore necessary to identify suitable tissue types. The results of Surowiec et al. (2011) illustrate that bone marrow should be excluded due to its high blood and lipid content. Furthermore, the use of the periosteum proteome was discarded in this study, since the periosteum could be unintentionally detached during processing, giving a false-positive result. Also, tendon-specific marker peptides might not be useful, since tendons can be found in meat products, even when good manufacturing practices are applied.

Intervertebral discs and cartilages are of special interest, because they are soft, i.e., they cannot be separated completely, and should inevitably occur in MSM. In addition, their proteome consists predominantly of collagens. Collagens are structural proteins (fiber bundle-forming proteins) and are found, among others, in the white, inelastic fibers of tendons, ligaments, bones, and cartilages. The collagen composition in the various compartments (tissue types) of the chicken is very different. While collagen II is predominantly found in intervertebral discs, cartilage contains both collagen I and II, while another collagen-rich material such as the chicken skin contains only collagen I (Ricard-Blum 2011). In conclusion, when MSM is used during the production of meat products, corresponding intervertebral disc or cartilage-specific proteins/peptides from chickens unavoidably end up in the sausages.

The detection of tissue or species-specific collagens/collagen fragments, in particular intervertebral disc / cartilage-specific collagens/collagen fragments, therefore could be indicative for the (non-)use of MSM in sausages and cold meat (Branscheid et al. 2009). A methodology with strong evidence, such as the LC–MS/MS, would take advantage of this fact and not directly detect MSM, but rather identify the content of cartilage or intervertebral disc material as an indirect marker (the course of the assay development and validation is shown in SF1 as graphical abstract).

Thus, in a first step, collagen-specific peptides for intervertebral discs/cartilage of chicken were identified by bottom-up LC–MS/MS. Afterwards, the intervertebral disc and cartilage-specific peptides were validated by the investigation of the following:

-

(1)

Pure collagen II alpha 1 (COL2A1) to confirm the origin of the specific peptides

-

(2)

High-pressure mechanically separated meat to validate that the selected peptides can be detected in pure MSM with high specificity

-

(3)

Purchased or specifically prepared real samples with various MSM contents in a blinded validation study

Materials and Methods

Animal Material

All chicken samples used in this study were commercially available and cover the complete range of slaughter chicken from discounters, from organic markets, peacock chicken, and soup chicken. This was to ensure the general applicability of the methodology. Twenty-seven whole chickens were purchased from retailers in and around Bremerhaven (Germany) and examined for this study. It was fresh discounter ware from different suppliers (19 samples) or goods from suppliers from organic rearing (5 samples) and frozen goods (3 samples) as well as 10 fresh thighs. The chickens and the 10 thighs were all processed in the same manner (supplementary Fig. SF2). The chickens were broken down into individual parts such as breast meat, skin, thigh meat, tendon, cartilage, and intervertebral discs. In addition, meat residues that were still adhered to the bone were scraped off manually with a scalpel. This scraped off meat contains material from the periosteum.

After the chickens had been dissected, the sample material (1.5–100 g; low amounts for intervertebral disc or cartilage material) was lyophilized (24 h, Alpha 1–2 LDplus; Christ GmbH, Germany), homogenized in a mixer (Nutrition Mixer, DS Produkte GmbH, Germany), and stored at − 20 °C until further use.

Sample Preparation

The enzymatic digestion of 0.3–0.5 g lyophilized sample (representing approx. 1–2 g of homogenized fresh sample) with thermolysin was carried out according to a protocol of Lasch et al. (2019). In brief, the lyophilized sample was dissolved in 8 mL ultra-pure water (Labtower™ 30 EDI; Thermo Fisher Scientific, Dreieich, Germany) and homogenized (Ultra-Turrax, 15,000 rpm, 1 min). Subsequently, the samples were heat-denatured (95 °C, 10 min), and after cooling (40 °C), 3 mg thermolysin (CAS-Nr: 9073–78-3, Geobacillus stearothermophilus; Sigma-Aldrich, Hamburg, Germany) in 2 mL ultra-pure water was added. After incubation (4 h, 37 °C), the enzyme was deactivated by heat denaturation (95 °C, 10 min). The samples were then centrifuged in 15-mL Falcon tubes (3800 g, 10 min, Universal 320R; Hettich, Germany). The resulting supernatant was decanted into 5-mL disposable syringes (VWR International GmbH, Darmstadt, Germany) and filtered through a HPLC syringe filter (Rotilabo®-syringe filters, pore size 0.45 µm, mixed cellulose ester (CME), Carl Roth GmbH + Co.KG, Karlsruhe). The protein content of the samples was determined (280 nm method) and then adjusted to a content of 2 mg/mL by dilution with ultra-pure water. The samples were stored in this state in the refrigerator at 4 °C until further use (Lasch et al. 2019).

LC–MS/MS

The LC–MS and LC–MS/MS analysis was performed as already described by Lasch et al. (2019) using an Eksigent 200 microLC-system online coupled to an AB Sciex TripleTOF 4600 (AB Sciex, Darmstadt, Germany) in positive electrospray modus. Digested samples (4 °C) were separated on a HALO Fused-Core C18 LC column (50 × 0.5 mm, 2.7 µm, 90 A; MZ Analysentechnik, Mainz, Germany) at 35 °C using a solvent gradient (Eluent A, water with 0.1% formic acid; Eluent B, acetonitrile with 0.1% formic acid) with Eluent A 97.5% for 0.5 min to 65% in 21 min to 5% in 0.5 min, constant for another 5 min and back to 97.5%. The flow rate was held at 20 µL/min. For each analysis, an aliquot of 5 µL of sample was injected.

Eluted peptides were analyzed in the information-dependent acquisition (IDA; Table 1) or pseudo-multiple reaction monitoring (pMRM; Table 1, 3) workflow using the Analyst software (v1.7.1; AB Sciex, Darmstadt, Germany). For CID-fragmentation, nitrogen was used as collision gas. The collision energy was optimized for each marker ion.

The pMRM transitions (also designated as MRMHR or PRM) are generated by cycling through the predefined set of the five precursor ions. Subsequently, full scan fragment ion spectra of each precursor are collected, and “pMRM”-transitions are reconstructed by the software (Higgs et al. 2013; Domon and Gallien 2015; Faktor et al. 2017). The pMRM transitions were optimized for the specific marker ions only, to improve the detection limit of the assay.

Definition of Specific Marker Ions (MarkerView)

For this purpose, bioinformatics (MarkerView 1.2.1; ABSciex, Darmstadt, Germany) was used to compile the data of the individual measurements and to sort them according to tissue type. The resulting peak list characterizes every marker ion by its m/z ratio as well as its molecular weight (kDa). All marker ions detected were matched and annotated for further comparison of sample groups. For clustering, marker ions in different samples were regarded as identical if the deviation in molecular weight was less than ± 0.05 Da and if the retention-time deviation was less than ± 0.5 min (Table 2).

The tissue type-specific marker ions were then defined by comparing the individual tissue types against all other samples, and the m/z lists were sorted according to the highest discriminatory value (minimum p < 0.05; t test). To define marker ions, the following quality-control and selection criteria were adapted:

-

(1)

One-fold-charged molecules are not accepted as candidates.

-

(2)

The mean signal intensity for marker ions must be more than 100,000 counts.

-

(3)

The frequency of occurrence of every candidate biomarker must be 100% in one of the groups (breast meat, tendon, skin, etc.).

-

(4)

The mean amplitude in a diagnostic group must be more than 100-fold higher than that of the comparison group.

-

(5)

MSMS experiments on the marker ions were successful (pMRM transitions could be allocated).

-

(6)

Marker ions identified as peptides show a minimal size of six amino acids.

Finally, principal component analysis (PCA) was used to evaluate the discriminative power by distinguishing the seven subgroups (skin, tendon, breast meat, scraped off meat, thighs, and offal vs intervertebral disc/cartilage) on the basis of the marker ions pattern. In general, only the two axes with the greatest variability are retained in PCA, and the result is displayed as a 2-D scatter plot (Lasch et al. 2019; Uhlig et al. 2019).

Identification of Specific Marker Ions

Protein identification was carried out by ProteinPilot V 5.0 (AB Sciex, Darmstadt, Germany). The database search was carried out with the Paragon search engine (Shilov et al. 2007) using the UniProt database from 26/11/2020. When automatic assignment of spectra by ProteinPilot was not successful, manual annotation (Δ m/z = ± 0.005) was performed using the Bio Tool Kit V. 2.2.0 (ABSciex, Darmstadt, Germany).

All spectra were checked with ProteinBlast (https://blast.ncbi.nlm.nih.gov/Blast.cgi) for correct assignment to the protein as well as for species specificity.

Verification of Protein Specificity with Pure COL2A1

Finally, pure collagen II alpha 1 (COL2A1) from chicken sternal cartilage (C9301, Sigma-Aldrich, Hamburg, Germany) was enzymatically digested to confirm the origin of the potential markers. For this purpose, the collagen was dissolved (1 mg/mL) in 0.1 M acetic acid and stirred for 2 days in the refrigerator. Five hundred microgram of protein were transferred to an Eppendorf vial and digested with 20 µg thermolysin analogously to the method described above without centrifugation and filtering of the sample.

Confirmation of Specific Marker ions in MSM

In order to confirm potential markers, eighteen samples of pure high-pressure mechanically separated meat from chicken were processed as described above (lyophilized, homogenized, digested) and examined by LC–MS/MS. High pressure MSM was selected, because in the case of chicken, it accounts for about 80% of the total mechanically separated meat produced (European Commission 2010).

Validation of the Assay by the Detection of Mechanically Separated Meat in Real Samples of Unknown Composition

To ensure the validity of the assay, a total of 42 real samples with unknown composition were examined in a blinded fashion. Eighteen negative control samples (NC) were prepared under supervision by different butchers in Northern Germany (supplementary Table ST1). It should be emphasized that two negative controls (NC 17, 18) were prepared using collagen hydrolysate (Albers Fleischereibedarf WB/Gelantine Eiweiß; Charge 04,042,018). This was to ensure that the possible use of such powders would not affect the validity of the assay. In addition, 20 positive control samples (PC) with MSM contents of 12–90% (median, 29%; mean, 41 ± 29%) were purchased (supplementary Table ST1). Furthermore, four additional samples were specifically produced by a master butcher. These samples were made of tight meat (manually deboned from chicken leg, 75%), chicken skin (15%), water (9%), curing salt (nitrite pickling salt), phosphate, and spices for the control sample (NC 19, 0% MSM). For the other three samples, the meat content was partially replaced by increasing amounts of MSM (5, 10, 20%).

All samples were then subjected in duplicates to the standardized sample preparation (lyophilized, homogenized, digested) ahead of the LC–MS/MS analysis. After classification of the samples (containing MSM yes/no), the samples were unblinded, and the precision of the method was determined.

Assignment of samples

The marker ions and the pMRM transitions were evaluated using the MasterView software tool (1.1, ABSciex Darmstadt, Germany) for the assignment of whether or not there is MSM in the (blinded) samples examined. For a positive assignment of a marker ion, a small difference in retention time (Δ t < ± 0.1 min) and a high mass accuracy (Δ m/z < ± 0.002 Da) are mandatory. Furthermore, only pMRM transitions with intensity (counts) ≥ 50 and a signal to noise ratio (SNR) of at least 3:1 were used, and at least three out of four MRM transitions must be detected, respectively.

Statistical Analysis

Calculations for median, mean value, and standard deviation were calculated in Excel® (Office 2019). The t test (p value < 0.05) and the PCA were performed in markerview (ABSciex, Darmstadt, Germany) as described by Lasch et al. (2019) and Uhlig et al. (2019).

Results

Currently, it is not possible to unambiguously identify mechanically separated meat in sausages and meat products. Hence, there is the possibility that labeling obligations are not always met. Consequently, even reputable producers are placed under the general suspicion of adding MSM undeclared, since negative evidence cannot be provided.

Using bottom-up LC–MS/MS, a detection method for mechanically separated meat from chickens in sausages was developed, to circumvent this issue. The detection was carried out indirectly via the detection of intervertebral disc and cartilage proteome-specific marker peptides. For this purpose, differences in the proteome of different chicken compartments such as breast meat, thigh meat, skin, tendons, offal, intervertebral discs/cartilage, and scraped off meat were identified by untargeted bottom-up LC–MS/MS.

Definition of Specific Marker ions for Invertebral Disc and Cartilage Material

Initial analysis runs revealed that the reproducible analysis of chicken samples is possible using bottom-up proteomics and that a set of identical peptides can be found in every chicken compartment investigated (data not shown). Hence, a typical marker ion (presumably peptide) pattern for each of the different chicken compartments could be established after thermolytic digestion based on a total of 36,722 m/z values using MarkerView.

Intervertebral disc material and cartilage is rich in collagens, especially collagen II. Therefore, it was expected that the potential marker ions (presumably peptides) for intervertebral disc and cartilage would mainly be assigned to collagens. Thus, a comparison between collagen-rich tissue types was given priority to rule out a false-positive classification. By comparing the mass lists of the tissue types skin, intervertebral disc/cartilage, and tendon, 3193 marker candidates could be defined, all of which had a p value of < 0.05. From those initially marker candidates, the best 200 with p values < 10−18 were chosen, resulting in a distinct separation of the subgroup intervertebral disc/cartilage from a combined group consisting of skin, tendon, breast meat, scraped off meat, thigh meat, and offal by principal component analysis (PCA, supplementary Fig. SF3).

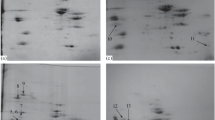

Out of this initial list, the specific marker ions were defined according to the criteria described above. As a result, a final selection of five specific marker ions (M1-5; Fig. 1) for intervertebral disc and cartilage was defined (Table 3), allowing the discrimination from all other tissue types investigated.

The five final marker peptides (m/z 564.278 (M1), 704.835 (M5), 826.702 (M3), 839.409 (M4), and 861.885 (M2)) are highlighted by circles in the MS-spectrum of pure COL2A1 after digestion with thermolysin. Inset: MS/MS-spectrum of the selected pMRM-transitions (m/z 630.328, 683.334, 1048.520, and 1365.659) shown for M4 (m/z = 839,409; twofold charged)

Investigation of Pure Collagen II Alpha 1 (COL2A1)

For two of the five marker ions (M3, M5; supplementary Figs. SF4, SF6), a UniProt database match to COL2A1 (CO2A1_CHICK, UniProt n.d.) was received with ProteinPilot. Besides, the described sequences of M3 and M5 occur in COL2A1 only and are almost exclusively assigned to the species “bird.” Exceptions have only been found in the marine environment (shark, herring, etc.) by Protein Blast. Although very good MS/MS spectra were available, one marker (M4; SF 5) could initially only be manually annotated (allowed mass deviation + / − 0.005 Da). A database search with ProteinPilot using an alternative database of unchecked sequences (uniprot_tremble.fasta; 090321) confirmed these annotations and allocated the sequence (in accordance with ProteinBlast) as COL2A1 (Q90W37_CHICK).

The marker ions M1 and M2 could not be assigned to any known amino acid sequences. But, characteristic mass differences of m/z = 162.05 were detected in the MSMS-spectra of M1 and M2 (supplementary Figs. SF7, SF8). In COL2A1 lysine is post-translationally 5-hydroxylated in some or all of the chains (in GxK-motifs). These hydroxy-lysine motifs are then additionally glycosylated with glucose-galactose (uniprot.org/uniprot/P02460#sequences). The cleavage of these sugar molecules would explain the observed mass differences of m/z = 162.05 (monomer) and m/z = 324.10 (dimer).

Nonetheless, it needs to be emphasized that the five marker ions in pure intervertebral disc and cartilage material, sausage samples, and in pure COL2A1 resulted in identical fragment spectra (SF4-8), so that all marker ions could be assigned to COL2A1 and are hereinafter referred to as marker peptides.

Marker Validation on High-Pressure Mechanically Separated Meat Samples

The five marker peptides were then applied to 18 samples of pure MSM. The aim of these investigations was to prove that the marker peptides for intervertebral disc and cartilage can be detected in chicken-MSM. The assignment of the marker peptide pattern on the pure MSM showed all markers as distinct positive with positive evidence for all pMRM transitions, respectively.

Blinded Marker Validation on Sausages and Cold Meat Samples with Different Amounts of Mechanically Separated Meat

Finally, the assay was applied and validated on two subsets of sausages with unknown proportions of MSM (supplementary Table ST1, ST2).

The first group consisted of 18 negative controls and 20 positive controls. These were either produced under supervision at butchers in northern Germany (negative controls) or purchased from different retailers (positive controls).

Another group of four blinded validation samples containing 0–20% MSM was then purposefully prepared by a master butcher, to estimate the limit of detection. Two samples were evaluated positive (10, 20% MSM). One sample (0% MSM) was correctly classified as negative, while one sample (5% MSM) was classified as negative, as only two out of the five markers were detectable (supplementary Table ST2).

In summary, after unblinding, it was found that all positive controls with MSM contents of 10–90% were correctly classified (overall sensitivity of the assay 96%). Likewise, all negative controls (even those with added collagen hydrolysate) were correctly classified (specificity of the assay 100%).

Finally, studies (n = 20) on chicken wings and mixtures of different chicken compartments showed that the sample homogeneity did not appear to affect correct classification of samples (data not shown).

Discussion

The assay developed defined specific marker peptides for intervertebral discs and cartilage of chicken. All marker peptides could be identified or assigned to chicken collagen II which proved to be a suitable marker for high-pressure MSM. Furthermore, it was shown that the detection of MSM in real samples such as sausages and cold meat was successfully implemented. A blinded study with a total of 42 samples revealed significant amounts of COL2A1 in the positive controls, whereas all negative controls showed no elevated COL2A1 levels. The sensitivity of the assay was 96%, and the specificity was 100% (overall precision 98%). Only one sample with MSM content of 5% was classified as negative for MSM.

It should be noted that the LC–MS/MS methodology could also detect lower levels of MSM (< 10%). However, workers boning meat with a knife may cut into the cartilage, allowing small pieces to penetrate the boned meat. Although this effect is less likely in poultry due to the cutting technique, the accidentally transferred cartilage pieces could lead to a false-positive result. Therefore, the selection rules for a positive classification were chosen conservatively, so that low levels of MSM (e.g., 5%) would rather be classified as “false negative” to avoid “false positive”.

Finally, two other important issues were addressed. First, the extent to which collagen hydrolysates can lead to a false-positive result was investigated. The negative controls produced for this purpose (NC 17, 18 (CH); ST2) were correctly classified as negative for MSM. Thus, it can be excluded that the use of collagen hydrolysates in sausage products influences the classification. Secondly, the extent to which sample homogeneity affects the classification was investigated. But here, too, it could be shown on differently homogenized samples that although the signal intensities fluctuate, the classification of the samples is not influenced (data not shown). Thus, the developed method has proven to be sensitive and specific even compared to established standard methods. Mohamed et al. (2016) have shown that below a level of 30% MSM, detection via calcium content or even histology is no longer reliable, and it was emphasized that no evidence for MSM at lower levels (10% MSM). In contrast, the proposed LC–MS/MS method has shown that detection of 10% MSM was successful even in commercially available real samples of varying composition (ST1,2).

In addition, in contrast to the LC–MS/MS-based approach by Surowiec et al. (2011) or a capillary gel electrophoresis-based approach by Day and Brown (2001), specific marker peptides were defined. These specific peptides are not based on blood or muscle components and could successfully be adapted to MSM-/non-MSM-samples of unknown composition. Significant advantages are also shown in comparison to a method currently published by Immarino (Iammarino et al. 2020) using liquid scintillation counting of 90Sr. Immarino achieves a precision of 61%, but in the case of MSM-containing samples, the sensitivity was only 22% (11 of 50 samples correctly classified). The sensitivity in terms of HP-MSM could be increased to 90% by using multiparameter analysis (90Sr; in addition, 88Sr/Ca by ICP/MS), but the lowest proportion of MSM in the samples was 20%, which is twice as high as in our approach. Similar results are described by Dalipi et al. (2018) which use total reflection X-ray fluorescence spectroscopy (TXRF) to detect low and high pressure MSM in meat and sausage samples. The method has been successfully developed and even tested on samples of unknown composition. However, the authors note that differentiation between MSM and fresh meat is only successful to an MSM content of 40%, which is four times higher as in this LC–MS/MS-assay.

Besides, the newly developed LC–MS/MS assay does not compete with recently presented methods by Wieja et al. (2021) and Wubshet et al. (2019). In both cases, the composition of meat and sausage products was successfully correlated with biochemical and chemical parameters such as fat, protein, and ash/calcium content. For this purpose, Wieja et al. correlated the determination of ultrasonic velocities in samples containing MSM to assess product quality, whereas Wubshet et al. successfully used Raman spectroscopy. However, in both cases, the aim is not to detect MSM in a regulatory context. Rather, the methods are intended to be used as a real-time method to monitor the composition of meat and sausage products, especially in an industrial environment.

Conclusion

In conclusion, the new assay allows the detection of much smaller amounts of MSM (10%) in commercially available meat samples compared to all currently established standard methods, such as microscopy, calcium detection, and liquid scintillation counting (20%) or TXRF (40%). Therefore, the assay addresses the need for new specific methods for the detection of MSM for food control authorities, as stated by the DLG. Furthermore, the method has the advantage that an all-encompassing biochemical and chemical characterization of sample material (lipid, protein, ash, Ca, carbohydrate, etc.) can be omitted, since the high specificity of the pMRM-transitions allows the selective detection of MSM-specific marker peptides.

Outlook

In the future, the assay will be adapted to other LC–MS/MS-platforms, such as tripleQuads, to ensure its general applicability. Initial investigations are promising here, since it has already been possible to detect all marker peptides and MRM transitions on an AB Sciex 5500 (GfL, data not shown). In addition, the exact structure of the presumably glycosylated marker peptides M1 and M2 remains to be elucidated.

Beyond that, similar assays will be developed for other species such as turkey and pork which have a significant impact in the MSM market. First investigations of turkey (data not shown due to small sample number) suggest that the detection of turkey MSM can also succeed on the basis of the intervertebral disc/cartilage proteome.

Moreover sheep, goat and cattle are of great importance since the use of MSM of these species is forbidden in the European Community due to health concerns.

Finally, the quantification of mechanical separated meat will be addressed in more detail. Even though the composition of MSM might vary from batch to batch, the use of synthesized marker peptides or synthesized and labeled marker peptides should allow a more precise estimation of the MSM content. In this context, the studies on low-pressure MSM will be extended. Up to now, only initial investigations have been carried out on low-pressure MSM. All specific peptides could also be detected in these (data not shown), but the number of samples is too small and method validation on blinded samples is pending.

Data Availability

All information regarding sample handling and processing are included in the manuscript or in the supplements.

Code Availability

No special software application except the mentioned original software tools supplied by the manufacturer of the mass spectrometry device is needed, and no customized software tools are used.

Abbreviations

- COL2A1:

-

Collagen II alpha 1

- COL2aA1:

-

Collagen IIa alpha 1

- IDA:

-

Information-dependent acquisition

- LC :

-

Liquid chromatography

- pMRM:

-

Pseudo-multiple reaction monitoring

- MPRM:

-

Mechanically recovered poultry meat

- MRM:

-

Multiple-reaction monitoring

- MS:

-

Mass spectrometry

- MSM:

-

Mechanically separated meat

- MS/MS:

-

Tandem mass spectrometry

- RT:

-

Retention time

- SNR:

-

Signal-to-noise ratio

- TOF:

-

Time of flight

References

Branscheid W, Judas M, Höreth R (2009) The morphological detection of bone and cartilage particles in mechanically separated meat. Meat Sci 81:46–50

Dalipi R, Berneri R, Curatolo M, Borgese L, Depero LE, Sangiorgi E (2018) Total reflection X-ray fluorescence used to distinguish mechanically separated from non-mechanically separated meat. Spectrochim Acta B 148:16–22

Day L, Brown H (2001) Detection of mechanically recovered chicken meat using capillary gel electrophoresis. Meat Sci 57:31–37. https://doi.org/10.1016/S0309-1740(00)00127-3

Deter A (2018). DLG-Medaille für Wurst aus Separatorenfleisch? https://www.topagrar.com/management-und-politik/news/dlg-medaille-fuer-wurst-aus-separatorenfleisch-9410232.html. Last access, Aug. 6th 2021

Domon B, Gallien S (2015) Recent advances in targeted proteomics for clinical applications. Proteomics Clin Appl 9:423–431. https://doi.org/10.1002/prca.201400136

European Commission (2001) Regulation (EC) No 999/2001. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32001R0999&from=DE,%20. Last access, Aug. 6th 2021

European Commission (2004) Directive Regulation (EC) No 853/2004 of the European Parliament and of the Council laying down specific hygiene rules for on the hygiene of foodstuffs. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32004R0853. Last access, Aug. 6th 2021.

European Commission (2005) Commission Regulation (EC) No 2074/2005. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32005R2074. Last access, Aug. 6th 2021

European Commission (2010) Communication from the commission to the European Parliament and the Council. COM (2010) 704 final. https://ec.europa.eu/transparency/regdoc/rep/1/2010/EN/1-2010-704-EN-F1-1.Pdf. Last access, Aug. 6th 2021

European Commission (2013) DG(SANCO) 2012–6355 - MR FINAL, Ref. Ares (2013)702140–16/04/2013. http://ec.europa.eu/food/audits-analysis/act_getPDF.cfm?PDF_ID=10318. Last access, Aug. 6th 2021

European Commission (2015) DG(SANTE)/2014–7278 – Final, Ref. Ares(2015)2035192 - 13/05/2015. Overview report of a series of audits carried out in 2012 and in 2013 in order to evaluate the control systems in place Governing the production of Mechanically separated meat. add: https://ec.europa.eu/food/auditsanalysis/overview_reports/act_getPDF.cfm?PDF_ID=357. Accessed 28 Feb 2022

Faktor J, Sucha R, Paralova V, Liu YS, Bouchal P (2017) Comparison of targeted proteomics approaches for detecting and quantifying proteins derived from human cancer tissues. Proteomics 17:1600323. https://doi.org/10.1002/pmic.201600323

Fiorino GM, Fresch M, Brümmer I, Losito I, Arlorio M, Brockmeyer J et al (2019) Mass spectrometry-based untargeted proteomics for the assessment of food authenticity: the case of farmed versus wild-type salmon. J AOAC Int. https://doi.org/10.5740/jaoacint.19-0062

Foodwatch (2014) 70.000 Tonnen Separatorenfleisch gesucht. https://www.foodwatch.org/fileadmin/foodwatch.de/news/Separatorenfleisch_Hintergrundpapier_final_2014-04-28_01.pdf. Last access, Aug. 6th 2021

Hassoun A, Mage I, Schmidt WF, Temiz HT, Li L, Kim H-Y et al (2020) Fraud in animal origin food products: advances in emerging spectroscopic detection methods over the past five years. Foods 9:1069. https://doi.org/10.3390/foods9081069

Higgs RE, Butler JP, Han B, Knierman MD (2013) Quantitative proteomics via high resolution MS quantification: capabilities and limitations. Int J Proteomics 2013:674282. https://doi.org/10.1155/2013/674282

Iammarino M, Miedico O, Petrella A, Mangiacotti M, Chiaravalle AE (2020) Innovative approaches for identifying a mechanically separated meat: evaluation of radiostrontium levels and development of a new tool of investigation. J Food Sci Technol 57(2):484–494. https://doi.org/10.1007/s13197-019-04076-y

Jira W, Schwägele F (2017) A sensitive high performance liquid chromatography–tandem mass spectrometry method for the detection of microbial transglutaminase in different types of restructured meat. Food Chem 221:1970–1978. https://doi.org/10.1016/j.foodchem.2017.06.030

Johnson PE, Downs M (2019) From signal to analytical reporting for allergen detection by mass spectrometry. J AOAC Int. https://doi.org/10.5740/jaoacint.19-0053

Langen M, Horn D (2020) Bildatlas Histologie Fleisch und Fleischerzeugnisse: Befunde beurteilen - Ergebnisse sicher bewerten, 1st edn. Behrs Verlag, Hamburg

Lasch P, Uhlig S, Uhlig C, Wilhelm C, Bergmann N, Wittke S (2019) Development and in-house validation of an LC-MS and LC-MS/MS assay for the determination of food fraud for different fish species. J AOAC Int. https://doi.org/10.5740/jaoacint.19-0061

Mohamed MA, Zahran DA, Kasem GMA, Emara MMT, Mansour NM (2016) Detection of mechanically recovered poultry meat (MRPM) in traditional Egyptian luncheon (emulsion type sausage). Pol J Food Nutr Sci 66(1):17–23. https://doi.org/10.1515/pjfns-2015-0013

Nollet L, Ötleş S (2020) Proteomics for food authentication, 1st edn. CRC Press, Boca Raton (ISBN 9780367205058)

Ortea I, O’Connor G, Maquet A (2016) Review on proteomics for food authentication. J Proteomics 147:212–255

Pickering K, Griffin M, Smethurst P, Hargin KD, Stewart CA (1995) Investigation of methods to detect mechanically recovered meat in meat products - IV: Immunology. Meat Sci 40:327–336

Pospiech M, Zikmund T, Javůrková Z, Kaiser J, Tremlová B (2019) An innovative detection of mechanically separated meat in meat products. Food Anal Methods 12:652–657

Premanandh J (2013) Horse meat scandal-A wake-up call for regulatory authorities. Food Control 34(2):568–569

Ricard-Blum S (2011) The collagen family. Cold Spring Harb Perspect Biol 3(1):a004978. https://doi.org/10.1101/cshperspect.a004978

Ruhland M, Klinger R (2019) Food fraud: a simple and efficient LC–MS/MS approach for peptide-based food authentication. J AOAC Int. https://doi.org/10.5740/jaoacint.19-0058

Shilov IV, Seymour SL, Patel AA, Loboda A, Tang WH, Keating SP et al (2007) The Paragon Algorithm, a next generation search engine that uses sequence temperature values and feature probabilities to identify peptides from tandem mass spectra. Mol Cell Proteomics 6:1638–1655. https://doi.org/10.1074/mcp.T600050-MCP200

Stader C, Judas M, Jira W (2019) A rapid UHPLC-MS/MS screening method for the detection of the addition of porcine blood plasma to emulsion-type pork sausages. Anal Bioanal Chem 41:6697–6709. https://doi.org/10.1007/s00216-019-02043-2

Stoyke M, Becker R, Brockmeyer J, Jira W, Popping B, Uhlig S et al (2019) German government official methods board points the way forward: launch of a new working group for mass spectrometry for protein analysis to detect food fraud and food allergens. J AOAC Int. https://doi.org/10.5740/jaoacint.19-0056

Surowiec I, Koistinen KM, Fraser PD, Bramley PM (2011) Proteomic approach for the detection of chicken mechanically recovered meat. Meat Sci 89:233–237

Tremlova B, Sarha P, Pospiech M, Buchtova H, Randulova Z (2006) Histologische Untersuchung verschiedener Arten von Separatorenfleisch. Arch Lebensmittelhyg 57:85–91

Trindade MA, de Felício PE, Contreras Castillo CJ (2004) Mechanically separated meat of broiler breeder and white layer spent hens. Sci Agric 61(2):234–239

Uhlig S, Colson B, Hettwer K, Simon K, Uhlig C, Wittke S et al (2019) Valid machine learning algorithms for multiparameter methods. ACQUAL. https://doi.org/10.1007/s00769-019-01384-w

UniProt COL 2A1, Gallus gallus. www.uniprot.org/uniprot/P02460#sequences. Last access Aug. 6th 2021

von Bargen C, Dojahn J, Waidelich D, Humpf HU, Brockmeyer J (2013) New sensitive high-performance liquid chromatography – tandem mass spectrometry method for the detection of horse and pork in halal beef. J Agric Food Chem 61:11986–11994. https://doi.org/10.1021/jf404121b

von Bargen C, Brockmeyer J, Humpf HU (2014) Meat authentication: a new HPLC − MS/MS based method for the fast and sensitive detection of horse and pork in highly processed food. J Agric Food Chem 62:9428–9435. https://doi.org/10.1021/jf503468t

Wieja K, Kiełczyński P, Szymański P, Szalewski M, Balcerzak A, Ptasznik S (2021) Identification and investigation of mechanically separated meat (MSM) with an innovative ultrasonic method. Food Chem 348:128907. https://doi.org/10.1016/j.foodchem.2020.128907

Wubshet SG, Wold JP, Böcker U, Wahlstrøm Sanden K, Afseth NK (2019) Raman spectroscopy for quantification of residual calcium and total ash in mechanically deboned chicken meat. Food Control 95:267–273. https://doi.org/10.1016/j.foodcont.2018.08.017

Funding

Open Access funding enabled and organized by Projekt DEAL. This research was funded in part by the German Federal Ministry of Economic Affairs and Energy (BMWi) “Central Innovation Programme for small and medium-sized enterprises (ZIM),” Project type: cooperative projects (KK), Funding Code: KK5125601BM0.

Author information

Authors and Affiliations

Contributions

1. Christian Wilhelm did the laboratory work by LC–MS/MS, wrote the draft of this report, reviewed the final version of this report, and supplied all figures and tables.

2. Mikko Hofsommer co-initiated this study, is co-inventor of the assay, and reviewed the report. He was also responsible for purchasing the positive controls and unblinding the study.

3. Prof. Dr. Stefan Wittke co-initiated the study, is co-inventor of the assay, and was the supervisor of C. Wilhelm. As the laboratory head, he supervised the laboratory work in the laboratory for Marine Biotechnology, wrote the final version of this report, and evaluated all data.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Conflict of Interest

Stefan Wittke and Mikko Hofsommer are the inventors of a patent application (Verfahren und Vorrichtung zum Nachweis von Schlachtnebenprodukten und/oder Separatorenfleisch) by the University of Applied Sciences Bremerhaven and GfL Gesellschaft für Lebensmittel-Forschung mbH in Germany on February 10th, 2020. The respective file number is 10 2020 103 267.6. On February 10th, 2021, an additional European patent application (using the priority of the German application) with the file number 21 156 405.9 was registered. Before funding (ZIM, started in 03.2021), Christian Wilhelm was paid in part by the GfL and the University of applied Sciences Bremerhaven and worked at the University of Applied Sciences in Bremerhaven in the laboratory for (Marine) Biotechnology. Moreover, it is important to emphasize that S. Wittke did not receive any personal financial support from the GfL and does not have any shares.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wilhelm, C., Hofsommer, M. & Wittke, S. Detection of Mechanically Separated Meat from Chicken in Sausages and Cold Meat by Targeted LC–MS/MS Analysis. Food Anal. Methods 15, 1899–1908 (2022). https://doi.org/10.1007/s12161-022-02231-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-022-02231-4