Abstract

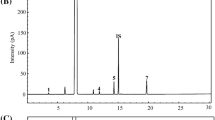

Fusel oils (FOs) are higher alcohols (including propanol, isobutanol, isoamylol, and active amyl alcohol), which affect the aroma profiles and flavor profiles of wine. A novel method for determination of FOs in lychee wine was developed using headspace gas chromatography (HS-GC). Results showed that 12% standard curve (SC) can be used to determinate the FOs of low alcoholic beverages, yet 40% SC can be used for high alcoholic beverages (e.g., brandy). Optimization of the parameters of equilibrium temperature at 50 °C was maintained for 30 min. The stabilized gas-liquid phase ratio of 3:1 for further research had no significant differences with others, which is caused by the distribution coefficient of K ≫ 100. The addition of sodium chloride (NaCl) decreased the partition coefficient of FOs markedly, and an inverse situation was observed for the extraction of FOs saturating at 1.25 g NaCl in 5 mL LW. Relative standard deviations (RSD) of reproducibility tests were in the range of 1.03–4.91%. Meanwhile, the mean recoveries of low, middle, and high concentration levels were 100.94, 103.2, and 96.74%, respectively. HS-GC was a stabilized, concise, and efficient method compared with the International Organization of Vine and Wine (OIV) method of OIV-MA-BS-14. These findings provide a foundation to determine higher alcohols of alcoholic beverages.

Similar content being viewed by others

References

Akubor P, Obio S, Nwadomere K, Obiomah E (2003) Production and quality evaluation of banana wine. Plant Food Hum Nutr 58:1–6

Almonds BB, Beetroot GE, Belitz H, Grosch W, Schieberle P (2009) Aroma compounds. In: Food chemistry, 4rd edn. Springer, Berlin, pp 340–402

Alves JA, de Oliveira Lima LC, Nunes CA, Dias DR, Schwan RF (2011) Chemical, physical–chemical, and sensory characteristics of lychee (Litchi chinensis Sonn) wines. J Food Sci 76:S330–S336

Alves JA, Lima LCDO, Dias DR, Nunes CA, Schwan RF (2010) Effects of spontaneous and inoculated fermentation on the volatile profile of lychee (Litchi chinensis Sonn) fermented beverages. Int J Food Sci Tech 45:2358–2365

AOAC (2005). Official methods of analysis of AOAC International: AOAC International

Bakierowska AM, Trzeszczyński J (2003) Graphical method for the determination of water/gas partition coefficients of volatile organic compounds by a headspace gas chromatography technique. Fluid Phase Equilib 213:139–146

Chai XS, Dhasmana B, Zhu JY (1998) Determination of volatile organic compound contents in kraft mill streams using headspace gas chromatography. J Pulp Pap Sci 24:50–54

Chai XS, Schork FJ, DeCinque A (2005) Simplified multiple headspace extraction gas chromatographic technique for determination of monomer solubility in water. J Chromatogr A 1070:225–229

Chen D, Chia JY, Liu S-Q (2014) Impact of addition of aromatic amino acids on non-volatile and volatile compounds in lychee wine fermented with Saccharomyces cerevisiae MERIT.Ferm. Int J Food Microbiol 170:12–20

Crank J (1975) The mathematics of diffusion, 2d edn. Oxford University Press, England

Dörmő N, Bélafi-Bakó K, Bartha L, Ehrenstein U, Gubicza L (2004) Manufacture of an environmental-safe biolubricant from fusel oil by enzymatic esterification in solvent-free system. Biochem Eng J 21:229–234

EC (2000) Laying down Community reference methods for the analysis of spirits drinks. Commission Regulation (EC) No 2870/2000 333:20–46

Falk A, Gullstrand E, Löf A, Wigaeus-Hjelm E (1990) Liquid/air partition coefficients of four terpenes. Brit J Ind Med 47:62–64

Fan A, Yuan W, Zhang H, Xue X, Qi X, Miao C (2012) Determination of aromatic components in chardonnay alcoholic fermentation by static headspace-GC-MS. China Brewing 3:047 (in Chinese)

Ferreira MC, Meirelles AJA, Batista EAC (2013) Study of the fusel oil distillation process. Ind Eng Chem Res 52:2336–2351

Güvenç A, Kapucu N, Kapucu H, Aydoğan Ö, Mehmetoğlu Ü (2007) Enzymatic esterification of isoamyl alcohol obtained from fusel oil: optimization by response surface methodolgy. Enzyme Microb Tech 40:778–785

Henrickson C (2005) Chemistry. Wiley, Hoboken

Hong J, Chen R, Zeng X-A, Han Z (2016) Effect of pulsed electric fields assisted acetylation on morphological, structural and functional characteristics of potato starch. Food Chem 192:15-24

Hough J, Stevens R (1961) Beer flavour. IV Factors affecting the production of fusel oil. J Inst Brew 67:488–494

Jones K, Wills R (1966) Separation and composition of a Scotch whisky fusel oil. J Inst Brew 72:196–201

Kolb B, Ettre LS (2006) Static headspace-gas chromatography: theory and practice. Wiley, Hoboken

Küçük Z, Ceylan K (1998) Potential utilization of fusel oil: a kinetic approach. Turk J Chem 22:289–300

Kuhn E, Thorngate J. (2003) Complete separation and quantification of fusel oils by capillary GC. Agilent Technologies

Kujawski W, Capala W, Palczewska-Tulinska M, Ratajczak W, Linkiewicz D, Michalak B (2002) Application of membrane pervaporation process to the enhanced separation of fusel oils. Chem Pap 5:3–6

Lee PR, Chong ISM, Yu B, Curran P, Liu SQ (2013) Effect of precursors on volatile compounds in papaya wine fermented by mixed yeasts. Food Technol Biotech 51:92–100

Lee PR, Ong YL, Yu B, Curran P, Liu SQ (2010) Profile of volatile compounds during papaya juice fermentation by a mixed culture of Saccharomyces cerevisiae and Williopsis saturnus. Food Microbiol 27:853–861

Lee PR, Yu B, Curran P, Liu SQ (2011) Effect of fusel oil addition on volatile compounds in papaya wine fermented with Williopsis saturnus var. mrakii NCYC 2251. Food Res Int 44:1292–1298

Liu Y, Yuan X (1995) Research on selection of headspace analysis condition of liquor. Journal of Zhenzhou University (Natural Science Edition) 27:80–84 (in Chinese)

Mestres M, Busto O, Guasch J (1997) Chromatographic analysis of volatile sulphur compounds in wines using the static headspace technique with flame photometric detection. J Chromatogr A 773:261–269

Musyimi S, Sila D, Okoth E, Onyango C, Mathooko F (2014) Production and characterization of wine from mango fruit (Mangifera indica) varieties in Kenya. Jomo Kenyatta University of Agriculture and Technology 16:3–19

Odabasi M, Cetin E, Sofuoglu A (2006) Determination of octanol–air partition coefficients and supercooled liquid vapor pressures of PAHs as a function of temperature: application to gas–particle partitioning in an urban atmosphere. Atmos Environ 40:6615–6625

OIV (2015) Compendium of international methods of analysis of wines and musts (2 vol.). http://www.oiv.int/public/medias/4005/compendium-2016-en-vol2.pdf. Accessed 10 July 2015

Osypenko O, Dolomakin Y, Osypenko V (2013) Сoncentration of fusel oil in alcohol column. Ukrainian Journal of Food Science 2:248–252

Patidar P, Mahajani SM (2012) Esterification of fusel oil using reactive distillation—part I: reaction kinetics. Chem Eng J 207–208:377–387

Rohrschneider L (1973) Solvent characterization by gas-liquid partition coefficients of selected solutes. Anal Chem 45:1241–1247

Sato A, Nakajima T (1979) Partition coefficients of some aromatic hydrocarbons and ketones in water, blood and oil. Brit J Ind Med 36:231–234

Schwarzenbach RP, Gschwend PM, Imboden DM (2005) Environmental organic chemistry. Wiley, Hoboken

Sulaiman AK (2010) Design of fusel oil separation column using Hysys program. Sudan Engineering Society Journal 56:53–60

Swiegers JH, Bartowsky EJ, Henschke PA, Pretorius IS (2005) Yeast and bacterial modulation of wine aroma and flavour. Aust J Grape Wine R 11:139–173

Tehrany EA, Mouawad C, Desobry S (2007) Determination of partition coefficient of migrants in food simulants by the PRV method. Food Chem 105:1571–1577

Ubeda C, Callejón RM, Hidalgo C, Torija MJ, Mas A, Troncoso AM, Morales ML (2011) Determination of major volatile compounds during the production of fruit vinegars by static headspace gas chromatography–mass spectrometry method. Food Res Int 44:259–268

Vilanoval M, Oliveira JM (2012) Application of gas chromatography on the evaluation of grape and wine aroma in Atlantic viticulture (NW Iberian Peninsula). In: Gas chromatography in plant science, wine technology, toxicology and some specific applications. Intech, European Union, pp 109–146

Villamor RR (2012) The impact of wine components on the chemical and sensory properties of wines. Dissertation, Washington State University

Wang L-H, Wang M-S, Zeng X-A, Zhang Z-H, Gong D-M, Huang Y-B (2016) Membrane destruction and DNA binding of cells induced by carvacrol and its combined effect with a pulsed electric field. J Agric Food Chem 64(32):6355-6363

Wang L-H, Wang M-S, Zeng X-A, Gong D-M, Huang Y-B (2017) An in vitro investigation of the inhibitory mechanism of β-galactosidase by cinnamaldehyde alone and in combination with carvacrol and thymol. Biochimica et Biophysica Acta (BBA) - General Subjects 1861(1):3189-3198

Whitmore FC, Olewine JH (1938) The separation of primary active amyl alcohol from fusel oil by distillation. J Am Chem Soc 60:2569–2570

Zeng XA, Chen XD, Zhang L, Qin FGF (2008) Composition analysis of litchi juice and litchi wine. Int J Food Eng 4:1556–3758

Zhu JY, Liu PH, Chai XS, Bullock KR, Teja AS (2000) Henry’s law constant of methanol in pulping spent liquors. Environ Sci Technol 34:1742–1746

Acknowledgements

This research was supported by the National Natural Science Foundation of China (21576099, 21376094) as well as S&T projects of Guangdong Province (2015A030312001 and 2013B020203001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Zhong-Sheng Tang declares that he has no conflict of interest. Xin-An Zeng declares that he has no conflict of interest. Charles S. Brennan declares that he has no conflict of interest. Wei-Qi Xie declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

About this article

Cite this article

Tang, ZS., Zeng, XA., Brennan, C.S. et al. A Novel Method for Detection of Fusel Oil in Wine by the Use of Headspace Gas Chromatography. Food Anal. Methods 10, 3338–3349 (2017). https://doi.org/10.1007/s12161-017-0884-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-0884-4