Abstract

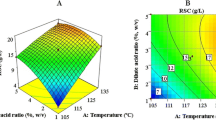

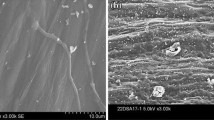

Rice straw hydrolysate produced in rice straw pretreatment, comprising a lot of fermentable sugars, is generally released into the environment. This not only causes environment pollution but also wastes fermentable sugars from rice straw. To alleviate environment impact, maximize ethanol production from rice straw, and reduce the cost of ethanol production, rice straw hydrolysate and NaOH-pretreated rice straw were converted to ethanol using ethanol-type fermentation and simultaneous saccharification and fermentation (SSF) by sludge. Meanwhile, microbial community in sludge was analyzed to find the relationship between ethanol production and microbial community succession during ethanol-type fermentation and SSF. Under the optimal condition of the COD, pH and oxidation–reduction potential (ORP) value of rice straw hydrolysate with 6280.56 mg/L, 6.7, and − 42 mV, ethanol-type fermentation with the sludge of 15 g obtained the highest ethanol concentration (8.34 g/L) and the highest COD removal rate (54.83%). For SSF, the maximum ethanol concentration (3.75 g/L) produced by pretreated rice straw and sludge from ethanol-type fermentation with the sludge of 15 g was higher than that (2.61 g/L) generated by pretreated rice straw and sludge from ethanol-type fermentation with the sludge of 22.5 g. This indicated that sludge from ethanol-type fermentation with the sludge of 15 g more efficiently converted rice straw to ethanol than sludge from ethanol-type fermentation with the sludge of 22.5 g. Microbial community analysis suggested that ethanol production had a negative correlation with the relative abundance changes of Bacteroidetes, when the relative abundance of Firmicutes constantly rose in ethanol-type fermentation and SSF. This study provides a scientific basis for maximizing ethanol production from rice straw by microbial regulation in sludge, which could further reduce the cost of ethanol production.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Chen L, Wang M, Zhang Z, Feng Y (2021) Application of electric potential improves ethanol production from xylose by active sludge. Biotechnol Biofuels 14:215. https://doi.org/10.1186/s13068-021-02065-y

Boboescu IZ, Gherman VD, Lakatos G, Pap B, Biro T, Maroti G (2016) Surpassing the current limitations of biohydrogen production systems: the case for a novel hybrid approach. Bioresour Technol 204:192–201. https://doi.org/10.1016/j.biortech.2015.12.083

Chen GY, Wang XT, Li J, Yan BB, Wang Y, Wu X (2019) Environmental, energy, and economic analysis of integrated treatment of municipal solid waste and sewage sludge: a case study in China. Sci Total Environ 647:1433–1443. https://doi.org/10.1016/j.scitotenv.2018.08.104

Xu Y, Gong H, Dai X (2021) High-solid anaerobic digestion of sewage sludge: achievements and perspectives. Front Env Sci Eng 15(4):71. https://doi.org/10.1007/s11783-020-1364-4

Zheng L, Xu Y, Geng H, Dai X (2022) Enhancing short-term ethanol-type fermentation of waste activated sludge by adding saccharomycetes and the implications for bioenergy and resource recovery. J Environ Sci 113:179–189. https://doi.org/10.1016/j.jes.2021.06.005

Liu K, Chen Y, Xiao N, Zheng X, Li M (2015) Effect of humic acids with different characteristics on fermentative short-chain fatty acids production from waste activated sludge. Environ Sci Technol 49:4929–4936. https://doi.org/10.1021/acs.est.5b00200

Lay CH, Lin HC, Sen B, Chu CY, Lin CY (2012) Simultaneous hydrogen and ethanol production from sweet potato via dark fermentation. J Clean Prod 27:155–164. https://doi.org/10.1016/j.jclepro.2011.12.027

Devendra LP, Pandey A (2016) Hydrotropic pretreatment on rice straw for bioethanol production. Renew Energ 98:2–8. https://doi.org/10.1016/j.renene.2016.02.032

Taherdazeh MJ, Karimi K (2007) Acid-based hydrolysis processes for ethanol from lignocellulosic materials: a review. Bioresour 2:472–499

Sekar R, Shin HD, Dichristina TJ (2016) Direct conversion of cellulose and hemicellulose to fermentable sugars by a microbially-driven Fenton reaction. Bioresour Technol 218:1133–1139. https://doi.org/10.1016/j.biortech.2016.07.087

Sriariyanun M, Gundupalli MP, Phakeenuya V, Phusamtisampan T, Cheng YS, Venkatachalam P (2024) Biorefinery approaches for production of cellulosic ethanol fuel using recombinant engineered microorganisms. J Appl Sci Eng 27(2):1985–2005. https://doi.org/10.6180/jase.202402_27(2).0001

Wang Y, Liu P, Zhang G, Yang Q, Lu J, Xia T, Peng L, Wang Y (2021) Cascading of engineered bioenergy plants and fungi sustainable for low-cost bioethanol and high-value biomaterials under green-like biomass processing. Renew Sust Energ Rev 137:110586. https://doi.org/10.1016/j.rser.2020.110586

Zhang R, Gao H, Wang Y, He B, Lu J, Zhu W, Peng L, Wang Y (2023) Challenges and perspectives of green-like lignocellulose pretreatments selectable for low-cost biofuels and high-value bioproduction. Bioresour Technol 369:128315. https://doi.org/10.1016/j.biortech.2022.128315

Jørgensen H, Kristensen JB, Felby C (2007) Enzymatic conversion of lignocellulose into fermentable sugars: challenges and opportunities. Biofuel Bioprod Bior 1:119–134. https://doi.org/10.1002/bbb.4

Zheng W, Chen X, Xue Y, Hu J, Gao MT, Tsang YF (2017) The influence of soluble polysaccharides derived from rice straw upon cellulase production by Trichoderma reesei. Process Biochem 61:130–136. https://doi.org/10.1016/j.procbio.2017.06.007

Sen B, Chou YP, Wu SY, Liu CM (2016) Pretreatment conditions of rice straw for simultaneous hydrogen and ethanol fermentation by mixed culture. Int J Hydrogen energ 41:4421–4428. https://doi.org/10.1016/j.ijhydene.2015.10.147

Zhang R, Hu Z, Wang Y, Hu H, Li F, Li M, Ragauskas A, Xia T, Han H, Tang J, Yu H, Xu B, Peng L (2023) Single-molecular insights into the breakpoint of cellulose nanofibers assembly during saccharification. Nat Commun 14:1100. https://doi.org/10.1038/s41467-023-36856-8

Zhang R, Hu Z, Peng H, Liu P, Wang Y, Li J, Lu J, Wang Y, Xia T, Peng L (2023) High density cellulose nanofibril assembly leads to upgraded enzymatic and chemical catalysis of fermentable sugars, cellulose nanocrystals and cellulase production by precisely engineering cellulose synthase complexes. Green Chem 25:1096–1106. https://doi.org/10.1039/D2GC03744K

Hans M, Kumar S, Chandel AK, Polikarpov I (2019) A review on bioprocessing of paddy straw to ethanol using simultaneous saccharification and fermentation. Process Biochem 85:125–134. https://doi.org/10.1016/j.procbio.2019.06.019

Afedzi AEK, Parakulsuksatid P (2023) Recent advances in process modifications of simultaneous saccharification and fermentation (SSF) of lignocellulosic biomass for bioethanol production. Biocatal Agr Biotech 54:102961. https://doi.org/10.1016/j.bcab.2023.102961

Ren N, Wang B, Huang JC (1997) Ethanol-type fermentation from carbohydrate in high rate acidogenic reactor. Biotechnol Bioeng 54:428–433. https://doi.org/10.1002/(SICI)1097-0290(19970605)54:5%3c428::AID-BIT3%3e3.3.CO;2-U

Li J, Zheng G, He J, Chang S, Qin Z (2009) Hydrogen-producing capability of anaerobic activated sludge in three types of fermentations in a continuous stirred-tank reactor. Biotechnol Adv 27(5):573–577. https://doi.org/10.1016/j.biotechadv.2009.04.007

Li Z, Lou Y, Ding J, Liu BF, Xie GJ, Ren NQ, Xing D (2020) Metabolic regulation of ethanol-type fermentation of anaerobic acidogenesis at different pH based on transcriptome analysis of Ethanoligenens harbinense. Biotechnol Biofuels 13:101. https://doi.org/10.1186/s13068-020-01740-w

Shi E, Li J, Zhang M (2019) Application of IWA Anaerobic Digestion Model No. 1 to simulate butyric acid, propionic acid, mixed acid, and ethanol type fermentative systems using a variable acidogenic stoichiometric approach. Water Res 161:242–250. https://doi.org/10.1016/j.watres.2019.05.094

Oh SE, Van Ginkel S, Logan BE (2003) The relative effectiveness of pH control and heat treatment for enhancing biohydrogen gas production. Environ Sci Technol 37:5186–5190. https://doi.org/10.1021/es034291y

Ren J, Sang Y, Ni J, Tao J, Lu J, Zhao M, Yao YF (2015) Acetylation regulates survival of Salmonella enterica serovar Typhimurium under acid stress. Appl Environ Microbiol 81:5675–5682. https://doi.org/10.1128/AEM.01009-15

Ryan D, Pati NB, Ojha UK et al (2015) Global transcriptome and mutagenic analyses of the acid tolerance response of Salmonella enterica serovar Typhimurium. Appl Environ Microbiol 81:8054–8065. https://doi.org/10.1128/AEM.02172-15

Croce S, Wei Q, D’Imporzano G, Dong R, Adani F (2016) Anaerobic digestion of straw and corn stover: the effect of biological process optimization and pre-treatment on total bio-methane yield and energy performance. Biotechnol Adv 34:1289–1304. https://doi.org/10.1016/j.biotechadv.2016.09.004

Gong M, Ren N, Xing D (2005) Start-up of hydrogen bio-production reactor and ethanol-type fermentation. Acta Energiae Solaris Sinica 26(2):244–247 (in Chinese)

Zhao Z, Zhang Y, Yu Q, Dang Y, Li Y, Quan X (2016) Communities stimulated with ethanol to perform direct interspecies electron transfer for syntrophic metabolism of propionate and butyrate. Water Res 102:475–484. https://doi.org/10.1016/j.watres.2016.07.005

Wang J, Chi Q, Pan L, Zhang R, Mu Y, Shen J (2023) New insights into enhanced biodegradation of 4-bromphenol in a nitrate-reducing system: process performance and mechanism. Water Res 242:120200. https://doi.org/10.1016/j.watres.2023.120200

Fu SF, He S, Shi XS, Katukuri NR, Dai M, Guo RB (2015) The chemical properties and microbial community characterization of the thermophilic microaerobic pretreatment process. Bioresour Technol 198:497–502. https://doi.org/10.1016/j.biortech.2015.09.029

Zhang S, Liu M, Chen Y, Pan YT (2017) Achieving ethanol-type fermentation for hydrogen production in a granular sludge system by aeration. Bioresour Technol 224:349–357. https://doi.org/10.1016/j.biortech.2016.11.096

Liu SC (2004) Analysis and measurement in papermaking industry. Chemical Industry Press, Beijing, pp 19–27

Krishna SH, Chowdary GV, Reddy DS, Ayyanna C (1999) Simultaneous saccharification and fermentation of pretreated Antigonum leptopus (Linn) leaves to ethanol. J Chem Technol Biot 74(11):1055–1060. https://doi.org/10.1002/(SICI)1097-4660(199911)74:11%3c1055::AID-JCTB148%3e3.3.CO;2-Q

Zhao Z, Zhang Y (2019) Application of ethanol-type fermentation in establishment of direct interspecies electron transfer: a practical engineering case study. Renew Energ 136:846–855. https://doi.org/10.1016/j.renene.2019.01.055

Zhao ZQ, Sun C, Li Y, Peng H, Zhang YB (2020) Upgrading current method of anaerobic co-digestion of waste activated sludge for high-efficiency methanogenesis: establishing direct interspecies electron transfer via ethanol-type fermentation. Renew Energ 148:523–533. https://doi.org/10.1016/j.renene.2019.10.058

Mohd-Zaki Z, Bastidas-Oyanedel JR, Lu Y, Hoelzle R, Pratt S, Slater FR, Batstone DJ (2016) Influence of pH regulation mode in glucose fermentation on product selection and process stability. Microorganisms 4(1):2. https://doi.org/10.3390/microorganisms4010002

Fang HHP, Liu H (2002) Effect of pH on hydrogen production from glucose by a mixed culture. Bioresour Technol 82:87–93. https://doi.org/10.1016/S0960-8524(01)00110-9

Liu CG, Xue C, Lin YH, Bai FW (2013) Redox potential control and applications in microaerobic and anaerobic fermentations. Biotechnol Adv 31:257–265. https://doi.org/10.1016/j.biotechadv.2012.11.005

Khongsay N, Lin YH, Laopaiboon P, Laopaiboon L (2014) Improvement of very-high-gravity ethanol fermentation from sweet sorghum juice by controlling fermentation redox potential. J Taiwan Ins Chem E 45:302–307. https://doi.org/10.1016/j.jtice.2013.07.011

Wang J, Zhao H, Zhang Q, Cai H, Wang P (2013) Application of a metal-insulator-semiconductor (MIS) sensor for extracellular redox potential detection. Sensor Actuat B: Chem 182:538–545. https://doi.org/10.1016/j.snb.2013.03.046

Chen X, Jiang S, Zheng Z, Pan L, Luo S (2012) Effects of culture redox potential on succinic acid production by Corynebacterium crenatum under anaerobic conditions. Process Biochem 47:1250–1255. https://doi.org/10.1016/j.procbio.2012.04.026

Lin YH, Chien WS, Duan KJ, Chang PR (2011) Effect of aeration timing and interval during very-high-gravity ethanol fermentation. Process Biochem 46:1025–1028. https://doi.org/10.1016/j.procbio.2011.01.003

Sanz JL, Rojas P, Morato A, Mendez L, Ballesteros M, González-Fernández C (2017) Microbial communities of biomethanization digesters fed with raw and heat pre-treated microalgae biomasses. Chemosphere 168:1013–1021. https://doi.org/10.1016/j.chemosphere.2016.10.109

Ren C, Wen Z, Xu Y, Jiang W, Gu Y (2016) Clostridia: a flexible microbial platform for the production of alcohols. Curr Opin Chem Biol 35:65–72. https://doi.org/10.1016/j.cbpa.2016.08.024

Zhao Z, Li Y, Quan X, Zhang Y (2017) New application of ethanol-type fermentation: stimulating methanogenic communities with ethanol to perform direct interspecies electron transfer. ACS Sustainable Chem Eng 5:9441–9453. https://doi.org/10.1021/acssuschemeng.7b02581

Ren N, Xing D, Rittmann BE, Zhao L, Xie T, Zhao X (2007) Microbial community structure of ethanol type fermentation in bio-hydrogen production. Environ Microbiol 9:1112–1125. https://doi.org/10.1111/j.1462-2920.2006.01234.x

Haapasalo M, Ranta H, Shah H, Ranta K, Lounatmaa K, Kroppenstedt RM (1986) Mitsuokella dentalis sp. nov. from dental root canals. Int J Syst Bacteriol 36:566–568. https://doi.org/10.1099/00207713-36-4-566

Ren N, Guo W, Wang X, Xiang W, Liu B, Wang X, Ding J, Chen Z (2008) Effects of different pretreatment methods on fermentation types and dominant bacteria for hydrogen production. Int J Hydrogen Energ 33:4318–4324. https://doi.org/10.1016/j.ijhydene.2008.06.003

Funding

This work was financially supported by the Natural Science Foundation of Hubei Province of China (2014CFB183) and the Foundation of Central Guidance on Local Science and Technology Development in China (2022BGE252).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Ji-Liang Lü, Zhen Wang, Min Tao, Han Zheng, Chao-Gang Lou, Shanshan Yang, and Xianli Liu. The first draft of the manuscript was written by Ji-Liang Lü, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lü, JL., Wang, Z., Tao, M. et al. Fermentation of Rice Straw and Its Hydrolysate with Sludge for Ethanol Production. Bioenerg. Res. (2024). https://doi.org/10.1007/s12155-024-10771-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12155-024-10771-2