Abstract

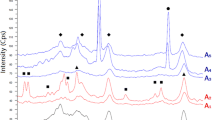

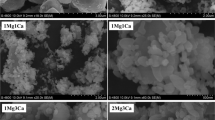

The catalytic transesterification of rapeseed oil toward biodiesel production was examined over four mixtures of MgO–CaO oxides as heterogeneous catalysts. The mixed oxidic system (100-x)MgO-(x)CaO, with x = 0, 1, 2, and 5 was synthesized via co-precipitation with ammonia in the presence of poly-vinyl-alcohol (PVA). The solid catalysts were characterized by X-ray powder diffraction (XRD), X-ray fluorescence spectroscopy (XRF), diffraction laser scattering (DLS), N2 adsorption-desorption porosimetry, and scanning electron microscopy/energy dispersive spectroscopy (SEM/EDS) techniques. The reaction took place in a stirred batch reactor where rapeseed oil was mixed with methanol, n-hexane, and the solid catalyst. Pure MgO oxide showed high catalytic activity, and the methyl ester yield was 97.7% while the gradual addition of CaO resulted in low methyl ester yield in the range 5–63%. This strong inhibition of the catalytic reaction was described phenomenologically by a standard deactivation formula. Τhe rapid drop of activity was attributed to the extensive flocculation of primary MgO crystallites triggered by the addition of CaO (~ 270 times larger). In this case, the reactants and/or products of the reaction suffer considerable diffusion limitations, probably of anomalous nature, in their way toward the active surface of MgO nanoparticle catalysts buried deep into the labyrinth of flocs made up of several hundreds of such active — but scarcely available — crystallites.

Similar content being viewed by others

Availability of Data and Material

Not applicable.

Code Availability

Not applicable.

References

Naik SN, Goud VV, Rout PK, Dalai AK (2010) Production of first and second generation biofuels: a comprehensive review. Renew Sust Energy Rev 14(2):578–597. https://doi.org/10.1016/j.rser.2009.10.003

Corma A, Iborra S, Velty A (2007) Chemical routes for the transformation of biomass into chemicals. Chem Rev 107(6):2411–2502. https://doi.org/10.1021/cr050989d

Margellou A, Kontominas M, Pomonis P (2019) Oilseed valorization for biodiesel production via catalytic transformation. In: Harvey L (ed) Oilseeds: Production, Varieties and Management Practices. Nova Science Publishers, pp 1–59

Tran NH, Kannangara GS (2013) Conversion of glycerol to hydrogen rich gas. Chem Soc Rev 42(24):9454–9479. https://doi.org/10.1039/c3cs60227c

Rodrigues A, Bordado JC, Santos RGd (2017) Upgrading the glycerol from biodiesel production as a source of energy carriers and chemicals-a technological review for three chemical pathways. Energies 10 (11):1817

Basha SA, Gopal KR (2012) A review of the effects of catalyst and additive on biodiesel production, performance, combustion and emission characteristics. Renew Sust Energ Rev 16(1):711–717. https://doi.org/10.1016/j.rser.2011.08.036

Koutsouki AA, Tegou E, Badeka A, Kontakos S, Pomonis PJ, Kontominas MG (2016) In situ and conventional transesterification of rapeseeds for biodiesel production: the effect of direct sonication. Ind Crops Prod 84:399–407. https://doi.org/10.1016/j.indcrop.2016.02.031

Koutsouki AA, Tegou E, Kontakos S, Kontominas MG, Pomonis PJ, Manos G (2015) In situ transesterification of Cynara cardunculus L. seed oil via direct ultrasonication for the production of biodiesel. Fuel Process Technol 134:122–129. https://doi.org/10.1016/j.fuproc.2015.01.024

Vicente G, Martinez M, Aracil J (2004) Integrated biodiesel production: a comparison of different homogeneous catalysts systems. Bioresour Technol 92(3):297–305. https://doi.org/10.1016/j.biortech.2003.08.014

Lam MK, Lee KT, Mohamed AR (2010) Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: a review. Biotechnol Adv 28(4):500–518. https://doi.org/10.1016/j.biotechadv.2010.03.002

Abdullah SHYS, Hanapi NHM, Azid A, Umar R, Juahira H, Khatoon H, Endut A (2017) A review of biomass-derived heterogeneous catalyst for a sustainable biodiesel production. Renew Sust Energ Rev 70:1040–1051. https://doi.org/10.1016/j.rser.2016.12.008

Georgogianni KG, Katsoulidis AP, Pomonis PJ, Kontominas MG (2009) Transesterification of soybean frying oil to biodiesel using heterogeneous catalysts. Fuel Process Technol 90(5):671–676. https://doi.org/10.1016/j.fuproc.2008.12.004

Boey PL, Maniam GP, Abd Hamid S (2011) Performance of calcium oxide as a heterogeneous catalyst in biodiesel production: a review. Chem Eng J 168(1):15–22. https://doi.org/10.1016/j.cej.2011.01.009

Liu XJ, He HY, Wang YJ, Zhu SL, Piao XL (2008) Transesterification of soybean oil to biodiesel using CaO as a solid base catalyst. Fuel 87(2):216–221. https://doi.org/10.1016/j.fuel.2007.04.013

Semwal S, Arora AK, Badoni RP, Tuli DK (2011) Biodiesel production using heterogeneous catalysts. Bioresour Technol 102(3):2151–2161. https://doi.org/10.1016/j.biortech.2010.10.080

Borges ME, Diaz L (2012) Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions: a review. Renew Sust Energ Rev 16(5):2839–2849. https://doi.org/10.1016/j.rser.2012.01.071

Kouzu M, Hidaka J (2012) Transesterification of vegetable oil into biodiesel catalyzed by CaO: a review. Fuel 93(1):1–12. https://doi.org/10.1016/j.fuel.2011.09.015

Sahu G, Gupta NK, Kotha A, Saha S, Datta S, Chavan P, Kumari N, Dutta P (2018) A review on biodiesel production through heterogeneous catalysis route. Chem Bioeng Rev 5(4):231–252. https://doi.org/10.1002/cben.201700014

Piker A, Tabah B, Perkas N, Gedanken A (2016) A green and low-cost room temperature biodiesel production method from waste oil using egg shells as catalyst. Fuel 182:34–41. https://doi.org/10.1016/j.fuel.2016.05.078

Chen G, Shan R, Shi J, Yan B (2014) Ultrasonic-assisted production of biodiesel from transesterification of palm oil over ostrich eggshell-derived CaO catalysts. Bioresour Technol 171:428–432. https://doi.org/10.1016/j.biortech.2014.08.102

Laskar IB, Rajkumari K, Gupta R, Chatterjee S, Paul B, Rokhum L (2018) Waste snail shell derived heterogeneous catalyst for biodiesel production by the transesterification of soybean oil. RSC Adv 8(36):20131–20142. https://doi.org/10.1039/c8ra02397b

El-Gendy N, Hamdy A, Abu Amr SS (2014) An investigation of biodiesel production from wastes of seafood restaurants. Int J Biomater 2014:609624. https://doi.org/10.1155/2014/609624

Almerindo GI, Probst LFD, Campos CEM, de Almeida RM, Meneghetti SMP, Meneghetti MR, Clacens J-M, Fajardo HV (2011) Magnesium oxide prepared via metal–chitosan complexation method: application as catalyst for transesterification of soybean oil and catalyst deactivation studies. J Power Sources 196(19):8057–8063. https://doi.org/10.1016/j.jpowsour.2011.05.030

Xu CL, Enache DI, Lloyd R, Knight DW, Bartley JK, Hutchings GJ (2010) Mgo catalysed triglyceride transesterification for biodiesel synthesis. Catal Lett 138(1–2):1–7. https://doi.org/10.1007/s10562-010-0365-5

Verziu M, Cojocaru B, Hu JC, Richards R, Ciuculescu C, Filip P, Parvulescu VI (2008) Sunflower and rapeseed oil transesterification to biodiesel over different nanocrystalline MgO catalysts. Green Chem 10(4):373–381. https://doi.org/10.1039/b712102d

Jeon H, Kim DJ, Kim SJ, Kim JH (2013) Synthesis of mesoporous MgO catalyst templated by a PDMS–PEO comb-like copolymer for biodiesel production. Fuel Process Technol 116:325–331. https://doi.org/10.1016/j.fuproc.2013.07.013

Margellou A, Koutsouki A, Petrakis D, Vaimakis T, Manos G, Kontominas M, Pomonis PJ (2018) Enhanced production of biodiesel over MgO catalysts synthesized in the presence of Poly-Vinyl-Alcohol (PVA). Ind Crops Prod 114:146–153. https://doi.org/10.1016/j.indcrop.2018.01.079

Taufiq-Yap YH, Lee HV, Yunus R, Juan JC (2011) Transesterification of non-edible Jatropha curcas oil to biodiesel using binary Ca-Mg mixed oxide catalyst: effect of stoichiometric composition. Chem Eng J 178:342–347. https://doi.org/10.1016/j.cej.2011.10.019

Fan M, Zhang P, Ma Q (2012) Enhancement of biodiesel synthesis from soybean oil by potassium fluoride modification of a calcium magnesium oxides catalyst. Bioresour Technol 104:447–450. https://doi.org/10.1016/j.biortech.2011.11.082

Buasri A, Rochanakit K, Wongvitvichot W, Masa-Ard U, Loryuenyong V (2015) The application of calcium oxide and magnesium oxide from natural dolomitic rock for biodiesel synthesis. Energy Procedia 79:562–566. https://doi.org/10.1016/j.egypro.2015.11.534

Bhatia SK, Gurav R, Choi TR, Kim HJ, Yang SY, Song HS, Park JY, Park YL, Han YH, Choi YK, Kim SH, Yoon JJ, Yang YH (2020) Conversion of waste cooking oil into biodiesel using heterogenous catalyst derived from cork biochar. Bioresour Technol 302:122872. https://doi.org/10.1016/j.biortech.2020.122872

Mandari V, Devarai SK (2021) Biodiesel production using homogeneous, heterogeneous, and enzyme catalysts via transesterification and esterification reactions: a critical review. Bioenergy Res:1-27. https://doi.org/10.1007/s12155-021-10333-w

Aghel B, Mohadesi M, Sahraei S (2018) Effect of different cosolvents on transesterification of waste cooking oil in a microreactor. Chem Eng Technol 41(3):598–605. https://doi.org/10.1002/ceat.201700025

Kim HJ, Kang BS, Kim MJ, Park YM, Kim DK, Lee JS, Lee KY (2004) Transesterification of vegetable oil to biodiesel using heterogeneous base catalyst. Catal Today 93–5:315–320. https://doi.org/10.1016/j.cattod.2004.06.007

Scholz F, Kahlert H (2015) The calculation of the solubility of metal hydroxides, oxide-hydroxides, and oxides, and their visualisation in logarithmic diagrams. ChemTexts 1(1):7. https://doi.org/10.1007/s40828-015-0006-0

Wei Z, Xu C, Li B (2009) Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresour Technol 100(11):2883–2885. https://doi.org/10.1016/j.biortech.2008.12.039

Correia LM, Campelo ND, Novaes DS, Cavalcante CL, Cecilia JA, Rodriguez-Castellon E, Vieira RS (2015) Characterization and application of dolomite as catalytic precursor for canola and sunflower oils for biodiesel production. Chem Eng J 269:35–43. https://doi.org/10.1016/j.cej.2015.01.097

Riekert L (1964) P. G. Ashmore: Catalysis and inhibition of chemical reactions. Butterworth & Co. Ltd., London 1963. 375 Seiten (15,5 × 24,65 cm) mit 128 Abbildungen. Preis: In. 75 s. Berichte der Bunsengesellschaft für physikalische Chemie 68 (10):999-1000. https://doi.org/10.1002/bbpc.19640681023

Seiyama T (1992) Total oxidation of hydrocarbons on perovskite oxides. Catal Rev Sci Eng 34(4):281–300. https://doi.org/10.1080/01614949208016313

Leontiou A, Ladavos A, Giannakas A, Bakas T, Pomonis P (2007) A comparative study of substituted perovskite-type solids of oxidic La1−xSrxFeO3±δ and chlorinated La1−xSrxFeO3±δClσ form: Catalytic performance for CH4 oxidation by O2 or N2O. J Catal 251(1):103–112. https://doi.org/10.1016/j.jcat.2007.07.012

Levenspiel O (1999) Chemical reaction engineering. Wiley, New York

Schmidt LD (2004) The engineering of chemical reactions, 2nd edn. Oxford University Press, Oxford

Iosifidis A, Petrakis DE, Pomonis PJ (2009) Anomalous diffusion during isopropanol decomposition on (ZrO2)1–x(CeO2)x catalysts. Appl Catal A: Gen 364(1–2):199–210. https://doi.org/10.1016/j.apcata.2009.05.053

Acknowledgements

We acknowledge the support from the Department of Plant Production of the Technological Educational Institute of Epirus in Arta, Greece and the Laboratory of Prof. G. Manos for their kind supply of the rapeseed oil.

Funding

This research project has been co-financed by the European Union (European Regional Development Fund- ERDF) (348151) and Greek national funds through the Operational Program “THESSALY- MAINLAND GREECE AND EPIRUS-2007-2013” of the National Strategic Reference Framework (NSRF 2007-2013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Margellou, A.G., Koutsouki, A.A., Petrakis, D.E. et al. Catalysis and Inhibition of Transesterification of Rapeseed Oil over MgO–CaO. Bioenerg. Res. 16, 528–538 (2023). https://doi.org/10.1007/s12155-022-10430-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-022-10430-4