Abstract

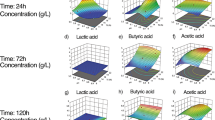

In a two-stage anaerobic digestion (AD) process approach, the relation between the type of fermentation that occurs during the acidogenic stage and methane production potential from tequila vinasse (TV) remains unexplored. This study aimed to investigate the effect of lactate fermentation type on the biochemical methane potential (BMP) of TV. To this end, a series of batch cultures were carried out to perform two sequential lactate-type fermentations, i.e., first (carbohydrates → lactate + acetate) and second (lactate + acetate → butyrate + H2) fermentation, which were further tested for mesophilic BMP using an automatic gas measuring device. Raw TV was also included in the comparison as a control (single-stage AD). During the primary fermentation, 75% of the total fermentable sugars were metabolized into lactate (12.6 g/L) and acetate (6.6 g/L) by the bacterial cluster mainly encompassing Klebsiella, Enterobacter, and Streptococcus, as supported by Illumina MiSeq sequencing analysis. During the secondary fermentation, lactate and acetate were bioconverted into butyrate (5.1 g/L) and hydrogen (115.6 NmL/g VSadded) by Clostridium. During methanogenesis, all tested feedstocks resulted in different BMP performances. The primary lactate fermentation led to the highest BMP (435.9 NmL CH4/g VSadded), methane production rate (105.8 NmL CH4/day), and chemical oxygen demand removal efficiency (92.9%), which were 46.2%, 89.3%, and 8.8%, respectively, higher than those attained from raw TV. Methanobacterium and Methanolinea dominated in the starter granular sludge culture, suggesting the hydrogenotrophic pathway was key for methane formation. This study shows for the first time the viability of the lactate-type fermentation for designing enhanced two-stage TV-fed AD processes.

Similar content being viewed by others

References

López-López A, Davila-Vazquez G, León-Becerril E, Villegas-García E, Gallardo-Valdez J (2010) Tequila vinasses: generation and full scale treatment processes. Rev Environ Sci Biotechnol 9:109–116. https://doi.org/10.1007/s11157-010-9204-9

Consejo regulador del Tequila (CRT). Available at: https://www.crt.org.mx/estadisticascrtweb/; 2018. Accessed 6 Jan 2020

Buitron G, Carvajal C (2010) Biohydrogen production from tequila vinasses in an anaerobic sequencing batch reactor: effect of initial substrate concentration, temperature and hydraulic retention time. Bioresour Technol 01:9071–9077. https://doi.org/10.1016/j.biortech.2010.06.127

van Lier JB, Mahmoud N, Zeeman G (2008) Anaerobic wastewater treatment, in biological wastewater treatment: principles modelling and design. IWA Publishing, London, pp 401–442. https://doi.org/10.1021/es00154a002

Lindner J, Zielonka S, Oechsner H, Lemmer A (2016) Is the continuous two-stage anaerobic digestion process well suited for all substrates? Bioresour Technol 200:470–476. https://doi.org/10.1016/j.biortech.2015.10.052

Ruggeri B, Tommasi T, Sanfilippo S (2015) Two-step anaerobic digestion process, in BioH2 & BioCH4 through anaerobic digestion. Springer-Verlag:161–191. https://doi.org/10.1007/978-1-4471-6431-9

Pohland FG, Ghosh S (1971) Developments in anaerobic stabilization of organic wastes: the two-phase concept. Environ Lett 1:255–266. https://doi.org/10.1080/00139307109434990

Kleerebezem R, Joosse B, Rozendal R, Van Loosdrecht MCM (2015) Anaerobic digestion without biogas? Rev Environ Sci Biotechnol 14:787–801. https://doi.org/10.1007/s11157-015-9374-6

Venkata Mohan S, Nikhil GN, Chiranjeevi P, Nagendranatha Reddy C, Rohit MV, Naresh Kumar A, Sarkar O (2016) Waste biorefinery models towards sustainable circular bioeconomy: critical review and future perspectives. Bioresour Technol 215:2–12. https://doi.org/10.1016/j.biortech.2016.03.130

Sträuber H, Lucas R, Kleinsteuber S (2016) Metabolic and microbial community dynamics during the anaerobic digestion of maize silage in a two-phase process. Appl Microbiol Biotechnol 100:479–491. https://doi.org/10.1007/s00253-015-6996-0

Feng K, Deng Z, Wang Q, Zhang Y, Zheng C (2020) Effect of pre-fermentation types on the potential of methane production and energy recovery from food waste. Renew Energy 146:1588–1595. https://doi.org/10.1016/j.renene.2019.07.127

Chen X, Yuan H, Zou D, Liu Y, Zhu B, Chufo A, Jaffar M, Li X (2015) Improving biomethane yield by controlling fermentation type ofacidogenic phase in two-phase anaerobic co-digestion of food wasteand rice straw. Chem Eng J 273:254–260. https://doi.org/10.1016/j.cej.2015.03.067

Zhou M, Yan B, Wong JWC, Zhang Y (2018) Enhanced volatile fatty acids production from anaerobic fermentation offood waste: a mini-review focusing on acidogenic metabolic pathways. Bioresour Technol 248:68–78. https://doi.org/10.1016/j.biortech.2017.06.121

Pipyn P, Verstraete W (1981) Lactate and ethanol as intermediates in two-phase anaerobic digestion. Biotechnol Bioeng 23:1145–1154. https://doi.org/10.1002/bit.260230521

Detman A, Mielecki D, Pleśniak Ł, Bucha M, Janiga M, Matyasik I, Chojnacka A, Jędrysek MO, Błaszczyk MK, Sikora A (2018) Methane-yielding microbial communities processing lactate-rich substrates: a piece of the anaerobic digestion puzzle. Biotechnol Biofuels 11:116. https://doi.org/10.1186/s13068-018-1106-z

Wu Y, Wang C, Liu X, Ma H, Wu J, Zuo J, Wang K (2016) A new method of two-phase anaerobic digestion for fruit and vegetable waste treatment. Bioresour Technol 211:16–23. https://doi.org/10.1016/j.biortech.2016.03.050

Satpathy P, Steinigeweg S, Siefert E, Cypionka H (2017) Effect of lactate and starter inoculum on biogas production from fresh maize and maize silage. Adv Microbiol 7:358–376. https://doi.org/10.4236/aim.2017.75030

Garcia-Aguirre J, Aymerich E, González-Mtnez de Goñi J, Esteban-Gutierrez M (2017) Selective VFA production potential from organic waste streams: assessing temperature and pH influence. Bioresour Technol 244:1081–1088. https://doi.org/10.1016/j.biortech.2017.07.187

García-Depraect O, Gómez-Romero J, León-Becerril E, López-López A (2017) A novel biohydrogen production process: co-digestion of vinasse and Nejayote as complex raw substrates using a robust inoculum. Int J Hydrog Energy 42:5820–5831. https://doi.org/10.1016/j.ijhydene.2016.11.204

García-Depraect O, Valdez-Vázquez I, Rene ER, Gómez-Romero J, López-López A, León-Becerril E (2019) Lactate and acetate based biohydrogen production through dark co- fermentation of tequila vinasse and nixtamalization wastewater: metabolic and microbial community dynamics. Bioresour Technol 282:236–244. https://doi.org/10.1016/j.biortech.2019.02.100

García-Depraect O, Rene ER, Diaz-Cruces VF, León-Becerril E (2019) Effect of process parameters on enhanced biohydrogen production from tequila vinasse via the lactate-acetate pathway. Bioresour Technol 273:618–626. https://doi.org/10.1016/j.biortech.2018.11.056

García-Depraect O, León-Becerril E (2018) Fermentative biohydrogen production from tequila vinasse via the lactate-acetate pathway: operational performance, kinetic analysis and microbial ecology. Fuel 234:151–160. https://doi.org/10.1016/j.fuel.2018.06.126

García-Depraect O, Rene ER, Gómez-Romero J, López-lópez A, León-Becerril E (2019) Enhanced biohydrogen production from the dark co-fermentation of tequila vinasse and nixtamalization wastewater: novel insights into ecological regulation by pH. Fuel 253:159–166. https://doi.org/10.1016/j.fuel.2019.04.147

Fuess LT, Ferraz ADN, Machado CB, Zaiat M (2018) Temporal dynamics and metabolic correlation between lactate-producing and hydrogen-producing bacteria in sugarcane vinasse dark fermentation: the key role of lactate. Bioresour Technol 247:426–433. https://doi.org/10.1016/j.biortech.2017.09.121

Fuess LT, Zaiat M, Augusto Oller do Nascimento C (2019) Novel insights on the versatility of biohydrogen production from sugarcane vinasse via thermophilic dark fermentation: impacts of pH-driven operating strategies on acidogenesis metabolite profiles. Bioresour Technol 286:121379. https://doi.org/10.1016/j.biortech.2019.121379

Asunis F, De Gioannis G, Isipato M, Muntoni A, Polettini A, Pomi R, Rossi A, Spiga D (2019) Control of fermentation duration and pH to orient biochemicals and biofuels production from cheese whey. Bioresour Technol 289:121722. https://doi.org/10.1016/j.biortech.2019.121722

Blanco VMC, Oliveira GHD, Zaiat M (2019) Dark fermentative biohydrogen production from synthetic cheese whey in an anaerobic structured-bed reactor: performance evaluation and kinetic modeling. Renew Energy 139:1310–1319. https://doi.org/10.1016/j.renene.2019.03.029

Holliger C, Alves M, Andrade D, Angelidaki I, Astals S, Baier U, Bougrier C, Buffière P, Carballa M, de Wilde V, Ebertseder F, Fernández B, Ficara E, Fotidis I, Frigon JC, de Laclos HF, Ghasimi DS, Hack G, Hartel M, Heerenklage J, Horvath IS, Jenicek P, Koch K, Krautwald J, Lizasoain J, Liu J, Mosberger L, Nistor M, Oechsner H, Oliveira JV, Paterson M, Pauss A, Pommier S, Porqueddu I, Raposo F, Ribeiro T, Rüsch Pfund F, Strömberg S, Torrijos M, van Eekert M, van Lier J, Wedwitschka H, Wierinck I (2016) Towards a standardization of biomethane potential tests. Water Sci Technol 74:2515–2522. https://doi.org/10.2166/wst.2016.336

Angelidaki I, Alves M, Bolzonella D, Borzacconi L, Campos JL, Guwy AJ, Kalyuzhnyi S, Jenicek P, van Lier J (2009) Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci Technol 59:927–934. https://doi.org/10.2166/wst.2009.040

APHA (2005) Standard methods for the examination of water and wastewater, 21st edn. American Public Health Association/American Water Works Association/Water Environmental Federation, Washington DC

RTLGenomics, Data analysis methodology. http://www.rtlgenomics.com/docs/Data_Analysis_Methodology.pdf. Accessed 15 Oct 2018

Strömberg S, Nistor M, Liu J (2014) Towards eliminating systematic errors caused by the experimental conditions in biochemical methane potential (BMP) tests. Waste Manag 34:1939–1948. https://doi.org/10.1016/j.wasman.2014.07.018

Moset V, Al-zohairi N, Møller HB (2015) The impact of inoculum source, inoculum to substrate ratio and sample preservation on methane potential from different substrates. Biomass Bioenergy 83:474–482. https://doi.org/10.1016/j.biombioe.2015.10.018

Schievano A, Tenca A, Lonati S, Manzini E, Adani F (2014) Can two-stage instead of one-stage anaerobic digestion really increase energy recovery from biomass? Appl Energy 124:335–342. https://doi.org/10.1016/j.apenergy.2014.03.024

Tao Y, Hu X, Zhu X, Jin H, Xu Z, Tang Q, Li X (2016) Production of butyrate from lactate by a newly isolated Clostridium sp. BPY5. Appl Biochem Biotechnol 179:361–374. https://doi.org/10.1007/s12010-016-1999-6

Cabrol L, Marone A, Tapia-Venegas E, Steyer JP, Ruiz-Filippi G, Trably E (2017) Microbial ecology of fermentative hydrogen producing bioprocesses: useful insights for driving the ecosystem function. FEMS Microbiol Rev 41:158–181. https://doi.org/10.1093/femsre/fuw043

Schwalm ND III, Mojadedi W, Gerlach ES, Benyamin M, Perisin MA, Akingbade KL (2019) Developing a microbial consortium for enhanced metabolite production from simulated food waste. Fermentation 5(4):98. https://doi.org/10.3390/fermentation5040098

Hung C, Cheng C, Guan D, Wang S (2010) Interactions between Clostridium sp. and other facultative anaerobes in a self-formed granular sludge hydrogen-producing bioreactor. Bioresour Technol 6:2–9. https://doi.org/10.1016/j.ijhydene.2010.06.010

Hung CH, Cheng CH, Guan DW, Wang ST, Hsu SC, Liang CM (2011) Interactions between Clostridium sp. and other facultative anaerobes in a self-formed granular sludge hydrogen-producing bioreactor. Int J Hydrog Energy 36:8704–8711. https://doi.org/10.1016/j.ijhydene.2010.06.010

Shah FA, Mahmood Q, Shah MM, Pervez A, Asad SA (2014) Microbial ecology of anaerobic digesters: the key players of anaerobiosis. Sci World J 21. https://doi.org/10.1155/2014/183752

Pol LWH, Lopes SIDC, Lettinga G, Lens PNL (2004) Anaerobic sludge granulation. Water Res 38:1376–1389. https://doi.org/10.1016/j.watres.2003.12.002

Toledo-Cervantes A, Guevara-Santos N, Arreola-Vargas J, Snell-Castro R, Méndez-Acosta HO (2018) Performance and microbial dynamics in packed-bed reactors during the long-term two-stage anaerobic treatment of tequila vinasses. Biochem Eng J 138:12–20. https://doi.org/10.1016/j.bej.2018.06.020

Arreola-Vargas J, Snell-Castro R, Rojo-Liera NM, González-Álvarez V, Méndez-Acosta HO (2018) Effect of the organic loading rate on the performance and microbial populations during the anaerobic treatment of tequila vinasses in a pilot-scale packed bed reactor. J Chem Technol Biotechnol 93:591–599. https://doi.org/10.1002/jctb.5413

Acknowledgments

Víctor F. Diaz-Cruces acknowledges CONACYT for the MSc scholarship 621447.

Funding

This work was financially supported by Fondo SENER- CONACYT Sustentabilidad Energética, Clúster Biocombustibles Gaseosos (project 247006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Diaz-Cruces, V.F., García-Depraect, O. & León-Becerril, E. Effect of Lactate Fermentation Type on the Biochemical Methane Potential of Tequila Vinasse. Bioenerg. Res. 13, 571–580 (2020). https://doi.org/10.1007/s12155-020-10093-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10093-z