Abstract

Concentration of biofuel feedstock crop production in specific regions of the USA is dependent on the relative comparative advantage of production in a specific region based on several agronomic and economic factors. For the southeastern region of the USA, energy cane and sweet sorghum have been identified as two feedstock crops with the greatest potential for further development of production. This study utilized field trial data from yield studies in Louisiana to develop estimates of feedstock crop production costs and biofuel feedstock input costs for these two crops. Results indicated that feedstock production costs on a harvest yield basis, as well as the related dry matter basis, were heavily dependent on yield level. Economic research from this study indicated that energy cane had a slight cost advantage compared with sweet sorghum, although production of sorghum in certain periods during the growing season was very cost competitive with energy cane.

Similar content being viewed by others

Introduction

As the production of bioenergy feedstock crops in the USA increases in response to the further development and expansion of the biofuel and bioenergy sectors, competition for agricultural land for the production of feedstock crops versus traditional agricultural crops will also increase. Competition for agricultural land will be expected to be more prevalent in some regions of the country than others, due to suitability of soil and climate to potential feedstock crops as well as other factors, and the magnitude of this increased demand for crop land would also be expected to be heavily influenced by alternative federal programs and policies which might develop relating to proposed national renewable portfolio standards, policies regulating carbon dioxide emissions, and other related energy/environmental issues [1]. Murphy et al. (2011) discussed the expected implications for land competition from a global perspective [2]. They concluded that the global demand for biofuels, perhaps reaching as high as 20–30% of total energy demand, will continue to increase the competition for land use between traditional crops and newer biofuel feedstock crops. They also conclude that the production of biofuel feedstock crops which exhibit strong sustainability criteria will continue to be important, with both supportive and competitive aspects related to food security.

Production of dedicated energy crops will only expand and compete for available agricultural land if the expected net returns from the production of those crops exceed expected net returns from the production of traditional agricultural crops. In the southeastern USA, biomass energy crops with the greatest potential for production area expansion include energy cane and sweet sorghum [3]. A more recent study which utilized simulation analysis to project future biomass feedstock availability at the national level projected the greatest increase in available biomass would come from energy crops, including perennial crops switch grass, miscanthus, and energy cane along with the annual crop sweet sorghum. Simulated biomass feedstock production levels indicated that by 2040, energy crop production would represent from 49.7 to 63.8% of estimated future biomass production, with the remaining shares distributed among forestry resources, agricultural residues, and waste resources [4].

This article presents research results from a study which investigated the expected production costs of producing energy cane and sweet sorghum as biofuel feedstock crops in the southeastern USA. Yield information from research trials conducted in Louisiana for these two feedstock crops was utilized along with cost estimates of field crop planting, cultivation, and harvest operations with the objective of determining the production cost per output unit of producing energy cane and sweet sorghum in alternative commercial production scenarios. Estimated crop production costs were then converted to measures of feedstock cost per dry matter unit which would be utilized as the primary input into biofuel production operations.

The range of potential energy crops which could be grown in the USA for biomass feedstock production is broad and diverse [4]. In addition to the alternative types of agricultural energy crops which could be grown, in terms of annual versus perennial crops and the range of potential crops within each crop type category, the range of production areas across the USA in which these crops could be produced is quite varied over a range of alternative climatic growing conditions. Research results presented here is focused on the economics of producing energy cane and sweet sorghum as feedstock crops in the southeastern USA. These results will be of interest to agricultural producers in the region who may be contemplating the addition of energy crop production to their farming operations. It would also be of benefit to biofuel and bioproduct manufacturers who may have an interest in utilizing these particular crops as feedstock input material. And finally, the feedstock production cost estimates presented here adds to the general body of knowledge and information which will eventually form the foundation and lead to the establishment of a viable commodity market for biomass feedstock material.

Review of Relevant Previous Research

Earlier work by Turhollow (1994) evaluated the comparative economics related to potential energy crop production of various feedstock types across regions of the USA [5]. This study identified the Midwest and South as the regions of the country with the greatest potential for feedstock crop production, with emphasis on sweet sorghum and energy cane. Macrelli et al. evaluated the technical and economic prospects of bioethanol produced from the lignocellulosic portions of sugar cane (bagasse and leaves) associated with the production of sugar cane bioethanol on Brazil [6]. Utilizing simulation analysis, results indicated that production of second generation bioethanol from sugar cane bagasse and leaves in Brazil was currently economically competitive starch-based bioethanol production in Europe and, further, that sugar cane bioethanol could be produced at a lower cost with enzyme costs continuing to decline and if subsidies were used to compensate for the opportunity cost from the sale of excess electricity.

Monge et al. evaluated the economic implications of lignocellulosic biofuel production utilizing energy cane and sweet sorghum in Texas under three different technologies: hydrolysis, pyrolysis, and gasification [7]. Simulation results indicated that improved feedstock availability and biofuel technological productivity would greatly enhance the feasibility probabilities of the production technologies to be economically self-sustaining. Another research study evaluating biomass sorghum production in Texas investigated the relationships between crop yields, water use efficiency, and economic returns under limited water resource conditions [8]. Results of the study concluded that while sorghum crop yields under irrigation were greater than non-irrigated (rain-fed) conditions and that dryland production of sorghum failed to yield positive net farm returns, there were no significant differences among various irrigation treatments evaluated, suggesting that acceptable crop biomass yield levels could be obtained with restricted amounts of irrigation water.

Kim and Day (2011) evaluated the composition of sugarcane, energy cane, and sweet sorghum as potential feedstock supply crops which would be processed at an existing raw sugar factory [9]. Although energy cane and sweet sorghum have different harvest periods during the year, this study showed that both crops were similar in structure and chemical composition and could be handled by existing sugarcane harvest and processing system. Challenges for commercial operation of these crops as biofuel feedstock inputs included determining the optimum conditions for milling, pretreatment, and enzymatic hydrolysis of each feedstock to maximize ethanol yields, feasibility of incorporating new crops into the existing sugar cane infrastructure, and possibility of partitioning feedstocks for both fuel and sugar during normal sugar cane processing season in Louisiana.

An earlier and related study evaluated the potential farm-level costs of producing energy cane as a biofuel feedstock [10]. This earlier study utilized energy cane research plot yields for the plant cane through third stubble crops to project expected energy cane yields for potentially longer crop cycles, with feedstock production costs (biofuel feedstock input costs) estimated per unit of dry matter. Research results presented here extend this earlier work by incorporating actual research plot yields of energy cane through harvest of a sixth stubble crop as well as the inclusion of field trial results for sweet sorghum produced for biomass.

Feedstock Cost Estimation Methods

The primary objective of this study was to estimate the expected production costs of biofuel feedstock crops under alternative season-long commercial production scenarios and then translate those production costs into an estimate of feedstock input cost per unit of dry matter associated with biofuel production. Estimation of feedstock costs per unit of output required three data components: (a) expected harvest yields for energy cane and sweet sorghum, (b) specification of alternative season-long cropping sequences which would meet required daily feedstock supply volumes at a processing facility, and (c) estimation of the variable and fixed production costs associated with each field operation involved in the planting, cultivation, and harvest of the feedstock crops. These estimation procedures used in this analysis are described in the following sections.

Feedstock Crop Yields

Energy cane feedstock yields employed in this study were crop yield field trial results from a much larger feedstock research project [11]. The objective of this broad-based project, sponsored by the US Department of Energy and the Sun Grant Initiative, was to address information gaps related to the implementation of a billion-ton US bioenergy industry by the year 2030 [3]. As part of the investigation of the potential for energy cane production as part of this overall project, energy cane field trials were conducted, starting in the fall of 2008, at eight locations across five southern states (Hawaii, Georgia, Louisiana, Mississippi, and Texas). Eleven energy cane genotypes (varieties) were evaluated for general assessment and winter hardiness screening to be included in the study. Five genotypes were eventually chosen as being deemed suitable for continued testing at more northern latitudes [11]. Observed energy cane yields varied greatly by variety and location. In general, higher yields were observed at more southern locations, the lowest yield at the most northern locations. Energy cane yields from the trials at St. Gabriel, LA, were generally at mid-range levels across all research locations.

Estimates of energy cane crop yields utilized in this study were taken from energy cane variety field trials conducted at the Louisiana State University AgCenter Sugar Research Station in St. Gabriel, LA [12]. The five selected varieties of energy cane were planted in 2008 in research plots on the station. These plots were harvested over the next 6 years to estimate the yield for the plant cane crop (harvested in 2009) and the first stubble through fifth stubble crops (harvested in 2010 through 2014). For purposes of this study, harvested crop yields were averaged across varieties to obtain an average expected yield per crop age. Average expected yield per total farm harvested land area unit was calculated by taking a weighted average yield over three alternative crop cycle lengths: harvest through third, fourth, and fifth stubble.

The calculation of a weighted average energy cane yield per harvested area unit over the entire farm (i.e., over the entire crop cycle) for each of the three energy cane harvest crop cycle lengths can be stated mathematically as follows:

where Ayld3, Ayld4, and Ayld5 represent the weighted average energy cane crop yield per hectare through harvest of a third, fourth, and fifth stubble crop, YldPc is the harvested yield per hectare for the plant cane crop, YldSt1, YldSt2, YldSt3, YldSt4, and YldSt5 are the harvested yields per hectare for the first stubble through fifth stubble crops, and the equation coefficients represent the percentage of farm acreage harvested of each crop stage. Numerator coefficients represent the percent of total farm area harvested for each specific crop age, and denominator coefficients represent the percent of total farm area harvested.

Weighted average energy cane crop yields over alternative crop cycle lengths are shown in Table 1. Two measures of crop yield per harvest area are presented here: (a) harvest yield and (b) dry matter yield. Producers typically measure crop yields based on the weight of the feedstock material at harvest in the field. Harvest yield levels in the field are relatively higher due to the high moisture content of the harvested feedstock at that point in time. In addition, transportation costs of hauling the harvested material from the farm either directly to a biofuel processor or to an intermediate drying facility would most likely be stated in terms of cost per harvest weight. Biofuel processors are more interested in the dry matter content, since this is the material which will be used as an input into the biofuel production process. As a result, the market price paid to feedstock producers would be based on the dry matter content of the feedstock material provided to the processor and would be stated in terms of price per dry matter weight. Therefore, both feedstock yield measures were included in this analysis. Average yield values for a crop cycle through harvest of third stubble were estimated to be 90.56 mg ha−1 (cane yield harvest weight) with an average dry matter content yield of 16.70 mg ha−1 of biomass. Similar average yield estimates for crop cycles through fourth and fifth stubble were calculated to be 88.66 and 87.74 mg ha−1 (harvest weight) and 17.28 and 18.07 mg ha−1 dry matter yield, respectively.

Estimated yields for sweet sorghum as a biofuel feedstock crop were taken from research trials conducted by the LSU AgCenter in 2012 and 2013 at the Iberia Research Station in Jeanerette, LA [13]. Selected sweet sorghum varieties in the non-irrigated yield trials included early, medium, and late maturity. Sweet sorghum maturity is controlled by the length of day or photoperiod. Varieties of sweet sorghum in the yield trials were planted monthly from early April to early June. Yield was estimated for six 15-day harvest periods. Yield results from these trials are shown in Table 2. The average sweet sorghum harvest yield across all varieties was estimated to be 72.41 mg ha−1 harvest weight, with a dry matter yield of 16.14 mg ha−1. The lowest harvest yields were observed in the first harvest period (July 15–Aug 1), while the highest average harvest yields were observed in the third harvest period (Aug 15–Aug 31). As these trials utilized first-generation sweet sorghum hybrid varieties in a non-irrigated production regime and are in line with some earlier studies in other locations, higher yields would be expected with the inclusion of irrigation as a production practice, development of more advanced hybrid varieties, and production practices tailored to the characteristics of particular sweet sorghum varieties.

Feedstock Cropping Sequence

Five alternative biofuel feedstock crop production sequences were simulated in this study to estimate the average expected feedstock production cost over a range of typical production alternatives. These alternative cropping sequences are presented in Table 3. Three energy cane production sequences were included. Each of these energy cane production alternatives included a 90-day harvest season, with harvest through third, fourth, and fifth stubble crops (scenarios 1–3). One exclusive sweet sorghum production option was included (scenario 4). This production sequence, also a 90-day harvest season, included equal production levels from each of the six sweet sorghum harvest periods. The final cropping sequence (scenario 5) represented a 180-day harvest season, with sweet sorghum harvested during the first 90 days of the harvest season and energy cane, through fifth stubble, harvested over the last 90 days of the harvest season.

For each of the five alternative feedstock production sequences evaluated in this study, the production area required to supply a processing facility with a fixed daily supply of feedstock biomass over a specified harvest season was determined. These required areas of production are shown in Table 4. Processing capacity utilized in this study was similar to what currently exists for sugarcane processing in Louisiana. With a processing capacity of 544 mg h−1 and a daily processing period of 24 h, the daily feedstock requirement for a processing facility at this specified capacity would be 13,056 mg day−1. Over a 90- and 180-day processing season, total biomass feedstock requirements would be 1,175,710 and 2,351,421 mg, respectively. Using these supply requirements along with the average energy cane and sweet sorghum yields presented earlier, total production areas required to meet supply demands were estimated. Required production areas for energy ranged from 12,982 ha for harvest through third stubble to 13,400 ha for harvest through fifth stubble. Required production areas of sweet sorghum, based on 15-day harvest periods, ranged from 4699 ha for the July 15 to July 30 period to 2037 ha for the Aug. 16 to Aug. 30 period.

Feedstock Production Costs

Farm level production costs for energy cane produced as a biofuel feedstock were estimated for three alternative production scenarios. Whole farm costs for the production of energy cane were estimated for crop cycles through the harvest of third stubble, fourth stubble, and fifth stubble. Production costs for seedcane expansion, planting, cultivation, and harvest operations for energy cane were developed from cost estimates for sugarcane, since the production practices for both crops are very similar. Seedcane expansion and planting operations would be expected to be very labor intensive, as is the case with sugarcane planting. Assuming that energy cane planting costs would be similar in magnitude to sugarcane planting costs, planting labor costs would account for approximately 47% of the initial hand planting operation phase and 40% of the secondary mechanical planting operation phase [14]. Cultivation costs of energy cane would involve some early season tillage, with the majority of variable costs comprised of fertilizer, herbicide, and insecticide expenses. A typical pesticide program would include one insecticide application and three to four herbicide applications during the growing season. These pesticide costs were estimated to be approximately $235 per hectare, representing 30% of total variable cultivation costs. Fertilization costs would be expected to increase by crop age, as greater levels of primary nutrients (nitrogen (N), phosphate (P), potash (K)) are required for production of older stubble cane. Nutrient application for energy cane used in this analysis was similar to that used in current sugarcane production. Application rates for N/P/K were 89.7/0.0/89.7 kg ha−1 for plant cane, 112.1/44.8/112.1 kg ha−1 for first stubble, and 123.3/44.8/112.1 kg ha−1 for older stubble crops. Estimated fertilization material costs for plant cane, first stubble, and older stubble energy cane production were estimated to be $166, $283, and $295 ha−1, representing 27, 36, and 38% of variable expenses per hectare, respectively. Harvest operations would be highly mechanized, as is the case with sugarcane. Harvest variable costs would include about 20% for labor and the remainder for fuel and repairs. A detailed explanation of the proposed energy cane seedcane expansion and production operations as they relate to farm production area has been described elsewhere, and those assumptions are incorporated into this analysis [10].

The distribution of whole farm area under production of energy cane for the three alternative production scenarios evaluated in this study is shown in Table 5. Percentage values in the table represent the percentage of total farm area in each energy cane production phase, including planting, cultivation, and harvest. Under a crop cycle through harvest of third stubble, 20% of the total farm area would be planted each year, with 3.3% hand planted and 19.7% mechanically planted. Total area harvested under this crop cycle would equal 80% of total farm area, with 3.9% harvested for seed and 76.1% harvested for biomass. With some plant cane and first stubble being harvested for replant as seed, the percent of total farm area harvested for biomass would include 16.4% from the plant cane crop, 19.7% from first stubble, 20.0% from second stubble, and 20.0% from third stubble. As area in energy cane production is kept for harvest in additional succeeding years (through fourth and fifth stubble), the percent of area harvested for biomass increases as the percent of land required for planting decreases. For crop cycle through harvest of a fourth stubble crop, 16.7% of total farm area is planted each year and 83.3% is harvested with 80.1% harvested for biomass and 3.9% harvested for seed. For crop cycle through harvest of a fifth stubble crop, 14.3% of total farm area is planted each year and 85.7% is harvested with 82.9% harvested for biomass and 3.3% harvested for seed.

Farm production area distributions by crop production phase were combined with production cost estimates for each production phase to develop estimated weighted average total farm area estimates of energy cane production costs per land area unit. These estimated production costs are shown in Table 6 for the three energy cane production scenarios. Estimates of variable and fixed production costs taken from values for the 2015 crop year for sugarcane in Louisiana were used to develop these energy cost estimates [14]. Production costs per land area unit for each crop production phase were multiplied by the percentage of total farm area for each production phase and summed to estimate weighted average production costs. For an energy cane production crop cycle through harvest of third stubble, total feedstock crop production costs were estimated to be $1357.87 ac−1, with $1027.79 ac−1 in variable production costs, and $330.08 ac−1 in fixed production costs. Total production costs through harvest of a fourth stubble crop were estimated to be $1380.83 ac−1, with $1048.86 in variable costs and $331.96 in fixed costs. Total production costs through harvest of a fifth stubble crop were estimated to be $1397.22 ac−1, with $1063.92 in variable costs and $333.31 in fixed costs.

The production cost estimates presented in Table 6 represent the annual expected whole farm costs assuming that the same production phase land rotation is maintained from 1 year to the next by planting a specified amount of land each year. Annualized estimates of energy cane variable production cost for one crop cycle, from the first year of planting through the last year of harvest, are presented in Table 7. These costs are disaggregated into (a) crop establishment costs, associated with seedcane harvesting and planting operations, and (b) biomass cultivation and harvest costs, associated with field operations on field to be harvested for biomass. The net present value of these total variable costs were estimated using an 8% discount rate and then were annualized using the annuity formula A = PV [0.08 / (1 − (1.08)−n)]. This annualized value was then divided by the average area per year devoted to crop establishment to result in an annualized crop establishment cost per acre. Variable crop establishment cost estimates in this analysis decreased as the crop cycle was expanded to include more years of harvest before replanting, while annualized biomass cultivation and harvest costs per acre increased only slightly for longer crop cycles.

Projected costs associated with the production of sweet sorghum are shown in Table 8. The six cost estimates listed are associated with each of the six possible production phases for sweet sorghum. The basic cost of producing a sweet sorghum crop, including estimates of the variable and fixed cost associated with each production operation, was estimated to be $1308.37 ha−1. This cost estimated includes expenses associated with all required phases of sweet sorghum production including pre-planting fallow operations, planting, fertilization, weed control, and harvest. Major components of estimated variable costs would include fallow land preparation, fertilization (98.7/67.2/67.2 kg ha−1 for N/P/K), and harvest costs, with seed and herbicide costs representing the remainder of variable production costs. Total variable costs were estimated to be $945.79 ha−1 with total fixed costs at $362.58 ha−1. Given the fact that harvest of sweet sorghum would occur prior to the end of the calendar year for some planting dates, some number of field disking would be required to maintain weed control through the end of the season. Estimated total per additional field disking was specified at approximately $22 ha−1, with $12 ha−1 in variable expense, and $10 ha−1 in fixed equipment cost. The number of post-harvest field diskings required for each sweet sorghum production phase, along with the associate production cost, is shown in Table 8.

Results

Estimated feedstock production costs per area and per output unit are shown in Table 9 for the five cropping sequences evaluated in this study. Average variable production cost for the three energy cane cropping sequences (scenarios 1–3) ranged from $1028 ha−1 for harvest through third stubble to $1064 ha−1 for harvest through fifth stubble. This slight increase in variable cost per hectare, as crop cycle is extended, is due to two factors. First, variable cultivation cost is slightly higher for stubble cane and for plant cane due to greater use of tillage and/or herbicide operations for weed control. A greater percentage of farm production area in older stubble energy cane crops for longer crop cycles results in a higher weighted average cultivation cost per farm hectare. Secondly, as crop cycle length extends to longer years, a greater portion of the farm production area is harvested for biomass, resulting in a higher average harvest cost per farm hectare. With estimated fixed costs at approximately $330 ha−1 for each of the three energy cane production scenarios, total production costs for energy cane feedstock production were estimated to range from $1358 to $1397 ha−1.

Variable cost for the sweet sorghum production scenario (scenario 4) was estimated to be somewhat lower than cost estimates for energy cane at $966 ha−1. Inclusion of fixed production costs for equipment resulted in a total production cost estimate for sweet sorghum production at $1345 ha−1, similar to estimates for energy cane. Average sweet sorghum production costs per hectare were weighted by the number of acres required during each of the six harvest seasons to provide a fixed supply of feedstock per day as listed in Table 4. A feedstock production scenario of 50% energy cane and 50% sweet sorghum (scenario 5) had estimated total average production costs of $1368 ha−1.

In addition to variable and fixed feedstock production costs, Table 9 also includes a charge for land rent. Since much of the land area devoted to biofuel feedstock crop production in the southeastern USA would be operated under a lease arrangement by a tenant farm operator, land rent is a charge which must be included in any evaluation of feedstock crop production economic feasibility. In this analysis, land rent was charged at a typical one sixth crop share, calculated at breakeven revenue. Using this rental calculation, estimated land rent charges were similar across the five cropping sequences, ranging from $269 ha−1 for the sweet sorghum scenario to $279 for the energy cane scenario through fifth stubble.

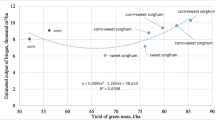

Using the average energy cane harvest yields for crop cycles through harvest of third, fourth, and fifth stubble, presented in Table 1, and the average sweet sorghum harvest yields for each harvest period, presented in Table 2, total feedstock production costs per harvest output unit were estimated. Total feedstock costs for the energy cane production scenarios ranged from $17.99 to $19.11 per harvest ton. Total estimated feedstock costs per unit for sweet sorghum were higher at $23.88 per harvest ton, due primarily to the lower relative average yields observed for sweet sorghum over the harvest periods. Converting these feedstock costs to a value per dry matter unit, using the dry matter yield values from Tables 1 and 2 yielded estimates of total feedstock cost per dry ton ranging from $92.80 to $97.57 t−1 for energy cane, $106.57 t–1 for sweet sorghum, and $99.97 t−1 for combined production of both feedstock crops. These cost estimates per unit of dry matter yield would represent input costs to a biofuel processing utilizing these energy cane or sweet sorghum crops as feedstock. For biofuel feedstock crop production to be economically viable and sustainable over the long run, revenue received from the sale of feedstock crop material would need to cover all associated production costs including any charges for land rent.

An important aspect of the establishment of a viable feedstock crop production sector is the ability of biofuel feedstock crops to compete for agricultural land with other agricultural crops traditionally grown in a specific region. For production of feedstock crops to be economically viable over the long run, the expected net returns per land area unit would need to be similar to or exceed expected net returns from crops currently in production. In the southeastern region of the USA, corn, cotton, rice, and soybeans are the primary major agricultural crops produced, with smaller total area in crops such as grain sorghum, peanuts, sugarcane, and wheat. Based upon regional production costs estimates by USDA, the feedstock production costs per hectare listed in Table 9 are similar to production cost estimates for corn ($1593 ha−1) and soybeans ($1272 ha−1) and are lower than cost estimates for cotton ($2668 ha−1) and rice ($2142 ha−1) [15]. Relative expected crop yields and market prices, and their impact on net returns, also are important factors in the comparative decision analysis of land use. The two feedstock crops evaluated in this study each have advantages and disadvantages which will impact their production economic viability. Energy cane would, in many cases, not require irrigation, as the production of sweet sorghum might. However, energy cane is a perennial crop, which would hold land in production of a single crop over a multi-year period, whereas sweet sorghum or other annual feedstock crops would have more flexibility of being incorporated into a farming operation’s production plans. And finally, the ability of feedstock crops to compete for agricultural land will depend, to large extent, on the establishment of a relatively predictable market price will low year-to-year variability. Most likely, this feedstock market price structure would be established initially through the use of price-specified production contracts, to ensure sufficient supplies of feedstock material, until a functional feedstock commodity market develops.

Conclusions

Agronomic and economic research evaluating the comparative advantage of producing alternative biofuel feedstock crops in various regions of the country has advanced to the point where more realistic analysis can be conducted regarding the feasibility of producing a specific feedstock crop in a specific region. A wider array of research field trials has been conducted across regions to provide more accurate and realistic estimates of expected feedstock crop yields produced in various areas under alternative production systems. Further, additional research efforts have provided more advanced and updated information regarding specific production practices required for producing feedstock crops with the goals of maximizing crop yields and minimizing production costs.

The objectives of the research study presented in this article were to estimate the expected production costs of producing energy cane and sweet sorghum as biofuel feedstock crops in the southeastern USA and to convert these production cost estimates into feedstock input costs on a dry matter basis. Harvest yields for the two crops were based on research trials through the end of three alternative crop cycle lengths for the perennial energy cane crop and over six alternative growing seasons for the annual sweet sorghum crop. Total production costs, including land rent, were estimated to be in the range of $18 to $24 per harvest weight ton. Conversion of production cost estimates to a dry matter basis indicated a slight advantage for energy cane over sweet sorghum, both in terms of dry matter yield and total production cost per dry matter unit. The lowest cost energy production scenario had estimated feedstock costs of approximately $93 per dry matter ton. Analysis projections by the Department of Energy would suggest a target feedstock cost of below $80 per dry ton, with average feedstock costs closer to $50–$60 t−1, as a long run goal for industry economic efficiency [4, 16]. As harvest yield and dry matter content are the most significant variables in determining eventual feedstock cost per dry matter unit, both of these agronomic factors would require further improvement to enhance the long-term economic viability of utilizing these two feedstock crops in a biofuel production process.

References

Sands RD, Malcolm SA, Suttles SA, and Marshall E (2017) Dedicated Energy Crops and Competition for Agricultural Land, U.S. Department of Agriculture, Economic Research Service, Economic Research Report No. 223

Murphy R, Woods J, Black M, McManus M (2011) Global developments in the competition for land from biofuels. Food Policy 36(Supplement 1):S52–S61

U. S. Billion-Ton Update: Biomass supply for a bioenergy and bioproducts industry, U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, August 2011

2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy, U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, July (2016)

Turhollow A (1994) The economics of energy crop production. Biomass Bioenergy 6:229–241

Macrelli S, Mogensen J, Zacchi G (2012) Techno-economic evaluation of 2nd generation bioethanol production from sugar cane bagasse and leaves integrated with the sugar-based ethanol process. Biotechnology for Biofuels 5:22

Monge JJ, Ribera LA, Jifon JL, da Silva JA, Richardson JW (2014) Economics and uncertainty of lignocellulosic biofuel production from energy cane and sweet sorghum in South Texas. J Agric Appl Econ 46(4):457–485

Enciso J, Jifon J, Ribera L, Zapata SD, Ganjegunte GK (2015) Yield, water use efficiency and economic analysis of energy sorghum in South Texas. Biomass Bioenergy 81:339–344

Kim M, Day DF (2011) Composition of sugar cane, energy cane, and sweet sorghum suitable for ethanol production at Louisiana sugar Mills. J Ind Microbiol Biotechnol 38:803–807

Salassi ME, Brown K, Hilbun BM, Deliberto MA, Gravois KA, Mark TB, Falconer LL (2014) Farm-scale cost of producing perennial energy cane as a biofuel feedstock. Bioenergy Research 7:609–619

Owens, V. N., D. L. Karlen, and J. A. Lacey et al. 2016 Regional feedstock partnership report: enabling the billion-ton vision—Appendix A: Energycane (Saccharum spp.). U.S. Department of Energy and Idaho National Laboratory

Gravois K, Finger M, Kimbeng C, Pontif M, and Baldwin B (2014) Yield and fiber content of high-fiber sugarcane clones. Sugar Research Station Annual Report, LSU AgCenter, pp 118–121

Viator HP (2015) Logistics for sustainable sweet sorghum biomass production. Louisiana Agriculture Magazine 58(2):12–13

Salassi ME, Deliberto MA and Hilbun BM (2015) Projected Costs and Returns Crop Enterprise Budgets for Sugarcane Production in Louisiana, 2015, LSU Agricultural Center, Dept. of Agricultural Economics and Agribusiness, A.E.A. Information Series No. 305

2015 Commodity Costs and Returns, U.S. Department of Agriculture, Economic Research Service, [www.ers.usda.gov/data-products/commodity-costs-and-returns/

2011 Feedstock Platform Review Report (2012) U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy

Acknowledgements

Research results presented in this article are based upon work that was supported by the National Institute of Food and Agriculture, US Department of Agriculture, under award number 2011-69005-30515.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Salassi, M.E., Holzapfel, A., Hilbun, B.M. et al. Feedstock Crop Production Costs and Biofuel Feedstock Input Costs Associated with the Production of Energy Cane and Sweet Sorghum in the Southeastern USA. Bioenerg. Res. 10, 772–782 (2017). https://doi.org/10.1007/s12155-017-9838-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-017-9838-3