Abstract

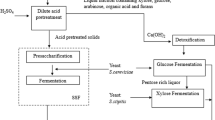

In this study, a central composite design and response surface methodology were used to study the effect of various hydrolysis variables (temperature, pH, and time) on the acid hydrolysis of Jerusalem artichoke-derived inulin using three different mineral acids (HCl, H2SO4, and H3PO4). Numerical optimization was used to maximize the sugar yield of Jerusalem artichoke powder within the experimental range for each of the mentioned acid. The influence of each acid on the formation of hydroxymethylfurfural (HMF; a known by-product and inhibitor for fermentative organisms) was also investigated. H2SO4 was found to have a better potential for sugar yields compared to two other acids (HCl and H3PO4) since it can hydrolyze the highest amount of inulin (98.5 %) under optimal conditions (temperature of 97 °C, pH of 2.0, and time period of 35 min) without producing inhibiting HMF concentrations. The sulfuric hydrolysate of Jerusalem artichoke was fermented via solventogenic clostridia to acetone-butanol-ethanol (ABE). An ABE yield of 0.31 g g−1 and an overall fermentation productivity of 0.25 g l−1 h−1 were obtained, indicating the suitability of this feedstock for fermentative ABE production.

Similar content being viewed by others

References

Schiel-Bengelsdorf B, Montoya J, Linder S, Dürre P (2013) Butanol fermentation. Environ Technol 34:1691–1710. doi:10.1080/09593330.2013.827746

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861. doi:10.1016/j.biortech.2009.11.093

Sánchez OJ, Cardona CA (2008) Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour Technol 99:5270–5295. doi:10.1016/j.biortech.2007.11.013

Sarchami T, Rehmann L (2014) Optimizing enzymatic hydrolysis of inulin from Jerusalem artichoke tubers for fermentative butanol production. Biomass Bioenergy 69:175–182. doi:10.1016/j.biombioe.2014.07.018

Jones DT, Woods DR (1986) Acetone-butanol fermentation revisited. Microbiol Rev 50:484–524

Dürre P (2007) Biobutanol: an attractive biofuel. Biotechnol J 2:1525–1534. doi:10.1002/biot.200700168

Qureshi N, Ezeji TC, Ebener J et al (2008) Butanol production by Clostridium beijerinckii. Part I: use of acid and enzyme hydrolyzed corn fiber. Bioresour Technol 99:5915–5922. doi:10.1016/j.biortech.2007.09.087

García V, Päkkilä J, Ojamo H et al (2011) Challenges in biobutanol production: how to improve the efficiency? Renew Sustain Energy Rev 15:964–980. doi:10.1016/j.rser.2010.11.008

Raganati F, Olivieri G, Procentese A et al (2013) Butanol production by bioconversion of cheese whey in a continuous packed bed reactor. Bioresour Technol 138:259–265

Gao K, Rehmann L (2014) ABE fermentation from enzymatic hydrolysate of NaOH-pretreated corncobs. Biomass Bioenergy 66:110–115. doi:10.1016/j.biombioe.2014.03.002

Szambelan K, Nowak J, Jelen H (2005) The composition of Jerusalem artichoke (Helianthus tuberosus L.) spirits obtained from fermentation with bacteria and yeasts. Eng Life Sci 5:68–71. doi:10.1002/elsc.200400052

Matías J, González J, Royano L, Barrena R (2011) Analysis of sugars by liquid chromatography-mass spectrometry in Jerusalem artichoke tubers for bioethanol production optimization. Biomass Bioenergy 35:2006–2012. doi:10.1016/j.biombioe.2011.01.056

Tasić MB, Konstantinović BV, Lazić ML, Veljković VB (2009) The acid hydrolysis of potato tuber mash in bioethanol production. Biochem Eng J 43:208–211. doi:10.1016/j.bej.2008.09.019

Pedersen M, Viksø-Nielsen A, Meyer AS (2010) Monosaccharide yields and lignin removal from wheat straw in response to catalyst type and pH during mild thermal pretreatment. Process Biochem 45:1181–1186. doi:10.1016/j.procbio.2010.03.020

Almeida RM, Modig T, Petersson A et al (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. Journal Chem Technol Biotechnol 349:340–349. doi:10.1002/jctb

Schwab K, Wood JA, Rehmann L (2013) Pyrolysis byproducts as feedstocks for fermentative biofuel production: an evaluation of inhibitory compounds through a synthetic aqueous phase. Ind Eng Chem Res 52:18234–18240. doi:10.1021/ie403354k

Razmovski R, Vucurovic V, Miljic U, Puskas V (2013) Effect of temperature on acid hydrolysis of Jerusalem artichoke as raw material for ethanol production. Acta Period Technol 44:279–287. doi:10.2298/APT1344279R

Jain VK, Baratti J (1985) Effect of acid or enzymatic hydrolysis on ethanol production by Zymomonaz mobilis growing on Jerusalem artichoke juice. Biotechnol Lett 530:527–530

Kim K, Hamdy MK (1986) Acid hydrolysis of Jerusalem artichoke for ethanol fermentation. Biotechnol Bioeng XXVIII:138–141

Razmovski RN, Šćiban MB, Vučurović VM (2011) Bioethanol production from Jerusalem artichoke by acid hydrolysis. Rom Biotechnol Lett 16:6497–6503

Bekers M, Grube M, Upite D et al (2007) Carbohydrates in Jerusalem artichoke powder suspension. Nutr Food Sci 37:42–49. doi:10.1108/00346650710726940

Szambelan K, Nowak J (2006) Acid and enzymatic hydrolysis of Jerusalem artichoke (Helianthus tuberosus) tubers for further ethanol production. Electron J Polish Agric Univ 9:36

Bekers M, Grube M, Upite D et al (2008) Inulin syrup from dried Jerusalem artichoke. LLU Raksti 21:116–121

Böhm A, Kaiser I, Trebstein A, Henle T (2004) Heat-induced degradation of inulin. Eur Food Res Technol 220:466–471. doi:10.1007/s00217-004-1098-8

Dao TH, Zhang J, Bao J (2013) Characterization of inulin hydrolyzing enzyme(s) in commercial glucoamylases and its application in lactic acid production from Jerusalem artichoke tubers (Jat). Bioresour Technol 148:157–162. doi:10.1016/j.biortech.2013.08.123

Zhang C, Houtman CJ, Zhu JY (2014) Using low temperature to balance enzymatic saccharification and furan formation during SPORL pretreatment of Douglas-fir. Process Biochem 49:466–473. doi:10.1016/j.procbio.2013.12.017

Zhu W, Houtman CJ, Zhu JY et al (2012) Quantitative predictions of bioconversion of aspen by dilute acid and SPORL pretreatments using a unified combined hydrolysis factor (CHF). Process Biochem 47:785–791. doi:10.1016/j.procbio.2012.02.012

Ezeji T, Qureshi N, Blaschek HP (2007) Butanol production from agricultural residues: impact of degradation products on Clostridium beijerinckii growth and butanol fermentation. 97:1460–1469. doi: 10.1002/bit

Zhang Y, Han B, Ezeji TC (2012) Biotransformation of furfural and 5-hydroxymethyl furfural (HMF) by Clostridium acetobutylicum ATCC 824 during butanol fermentation. N Biotechnol 29:345–351. doi:10.1016/j.nbt.2011.09.001

Qureshi N, Bowman MJ, Saha BC et al (2012) Effect of cellulosic sugar degradation products (furfural and hydroxymethyl furfural) on acetone–butanol–ethanol (ABE) fermentation using Clostridium beijerinckii P260. Food Bioprod Process 90:533–540. doi:10.1016/j.fbp.2011.09.002

Guo L, Zhang J, Hu F et al (2013) Consolidated bioprocessing of highly concentrated Jerusalem artichoke tubers for simultaneous saccharification and ethanol fermentation. Biotechnol Bioeng 110:2606–2615. doi:10.1002/bit.24929

Gao K, Li Y, Tian S, Yang X (2012) Screening and characteristics of a butanol-tolerant strain and butanol production from enzymatic hydrolysate of NaOH-pretreated corn stover. World J Microbiol Biotechnol 28:2963–2971. doi:10.1007/s11274-012-1107-1

Chen L, Xin C, Deng P, Ren J, Liang HBF (2010) Butanol production from hydrolysate of Jerusalem artichoke juice by Clostridium acetobutylicum L7. Chin J Biotechnol 26:991–996

Shaheen R, Shirley M, Jones DT (2000) Comparative fermentation studies of industrial strains belonging to four species of solvent-producing clostridia. J Mol Microbiol Biotechnol 2:115–124

Yerushalmi L, Volesky B, Leung WK, Neufeld RJ (1983) Variations of solvent yield in acetone-butanol fermentation. Eur J Appl Microbiol Biotechnol 18:279–286

Napoli F, Olivieri G, Russo ME et al (2011) Continuous lactose fermentation by Clostridium acetobutylicum—assessment of acidogenesis kinetics. Bioresour Technol 102:1608–1614. doi:10.1016/j.biortech.2010.09.004

Lee SY, Park JH, Jang SH et al (2008) Fermentative butanol production by Clostridia. Biotechnol Bioeng 101:209–228. doi:10.1002/bit.22003

Acknowledgments

The authors wish to thank the Institute for Chemicals and Fuels from Alternative Resources (ICFAR) for providing Jerusalem artichoke tubers as well as the Sand Plains Community Development Fund, Agriculture Canada, Natural Sciences and Engineering Research Council of Canada (NSERC), and the Canada Foundation for Innovation (CFI) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarchami, T., Rehmann, L. Optimizing Acid Hydrolysis of Jerusalem Artichoke-Derived Inulin for Fermentative Butanol Production. Bioenerg. Res. 8, 1148–1157 (2015). https://doi.org/10.1007/s12155-014-9568-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-014-9568-8